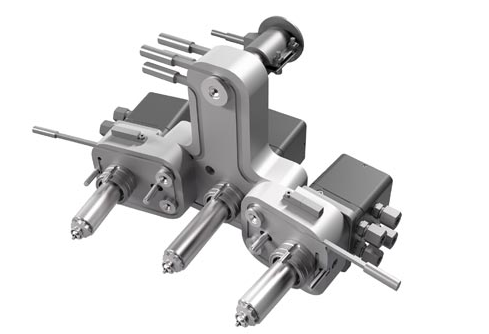

A hot runner system in injection molding is a sophisticated component of the mold that keeps the plastic in a molten state as it travels from the injection molding machine to the mold cavities. This system eliminates the need for runners that solidify and are typically discarded or recycled in a traditional cold runner system. By maintaining the plastic in a liquid state within the hot runner, these systems improve efficiency, reduce waste, and enhance the quality of the molded parts.

Key Components of a Hot Runner System

- Manifold

- The manifold distributes the molten plastic from the injection unit to the various nozzles. It is heated to maintain the plastic in a molten state.

- Nozzles

- The nozzles deliver the molten plastic directly into the mold cavities. They are also heated and can come in various designs depending on the application, such as valve-gated or open nozzles.

- Heaters

- Electric heaters are embedded in the manifold and nozzles to maintain the required temperature. Proper temperature control is crucial to ensure consistent melt flow.

- Temperature Controllers

- These devices regulate the temperature of the heaters to ensure the plastic remains at the correct viscosity for injection.

- Sprue Bushing

- The sprue bushing connects the hot runner system to the injection molding machine. It serves as the entry point for the molten plastic into the manifold.

Advantages of Hot Runner Systems

- Reduced Waste

- Hot runner systems eliminate the need for runners that cool and solidify, thus reducing material waste and saving costs on raw materials.

- Improved Part Quality

- Consistent melt temperature and flow can lead to higher quality parts with better surface finish, reduced warpage, and fewer defects.

- Shorter Cycle Times

- By eliminating the cooling time required for solid runners, hot runner systems can significantly reduce cycle times and increase production efficiency.

- Enhanced Design Flexibility

- Hot runners allow for more complex and intricate part designs as the plastic can be delivered precisely and consistently to different areas of the mold.

- Lower Clamping Force

- Since there is no need to accommodate solid runners, the clamping force required can be lower, reducing wear on the mold and the injection molding machine.

[elementor-template id=”4330″]

Disadvantages of Hot Runner Systems

- Higher Initial Cost

- Hot runner systems are more complex and expensive to design, manufacture, and install compared to cold runner systems.

- Maintenance Complexity

- Maintenance and repair of hot runner systems can be more challenging and require specialized knowledge and equipment.

- Potential for Thermal Degradation

- If not properly controlled, the prolonged heating of the plastic can lead to thermal degradation, affecting the quality of the parts.

Applications of Hot Runner Systems

Hot runner systems are used in a variety of industries, including:

- Automotive

- Production of complex components such as dashboards, door panels, and various under-the-hood parts.

- Consumer Goods

- Manufacturing of high-volume products like packaging, containers, and household items.

- Electronics

- Production of small, detailed components such as connectors, housings, and various electronic parts.

- Medical Devices

- Fabrication of high-precision, high-quality medical components and equipment.

Example of a Hot Runner System in Use

Consider the production of a multi-cavity mold for plastic bottle caps:

- Injection Phase: The molten plastic is injected into the hot runner system via the sprue bushing.

- Distribution: The manifold distributes the molten plastic to several nozzles, each aligned with a mold cavity.

- Cavity Filling: The heated nozzles inject the molten plastic directly into the mold cavities. The consistent temperature maintained by the hot runner system ensures uniform filling and minimizes defects.

- Cooling and Ejection: After the cavities are filled, the mold cools, and the finished bottle caps are ejected. There are no solid runners to remove, which simplifies the process and reduces cycle time.

[elementor-template id=”4331″]

Conclusion

A hot runner system in injection molding is a powerful tool that offers significant advantages in terms of material efficiency, part quality, and production speed. While it involves higher initial costs and complexity, the benefits often outweigh the drawbacks, particularly in high-volume production scenarios or when producing complex parts. Proper design, maintenance, and control of the hot runner system are crucial to maximizing its benefits and ensuring the consistent production of high-quality molded parts.

Related Conten: Mold Manufacturing / Plastic Blow Molding

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|