The Ultimate Guide to Plastisol for Fishing Lures: Properties, Blending, and Injection Molding Tips

For any brand or manufacturer in the fishing tackle industry, the heart of a great soft plastic lure isn’t just the design—it’s the material. Plastisol for lures is the industry-standard polymer that brings those lifelike crawfish, shrimps, and creatures to life. Its unique properties allow for incredible detail, durability, and flexibility that fish find irresistible. But to consistently produce high-quality baits that perform and sell, you need more than just good soft plastic lure material; you need to master it.

This guide is designed to do just that. We’ll dive deep into what makes Plastisol tick, how to customize it for perfect action, and, critically, how to process it correctly in your injection molding machines. Ultimately, mastering your material is the first step toward reducing waste, improving efficiency, and gaining a competitive edge. And from our perspective as a leading mold manufacturer and molder, we’ll share insights that bridge the gap between material science and production reality.

Plastisol 101: The Chemistry and Core Properties

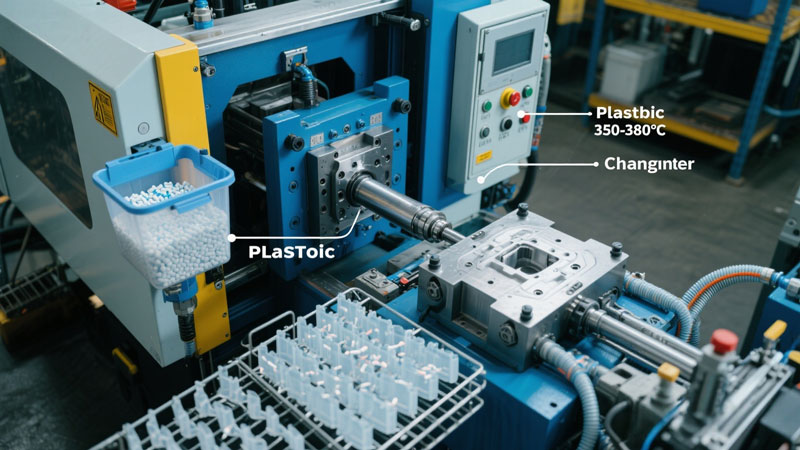

So, what exactly is this widely used material? At its core, Plastisol is a suspension of Polyvinyl Chloride (PVC) resin particles in a plasticizer (a liquid that makes the PVC soft and flexible). It’s a liquid at room temperature but transforms into a solid, rubber-like plastic when heated to a specific injection molding temperature for Plastisol (typically between 350°F and 380°F / 177°C and 193°C).

This phase change is what makes it ideal for creating intricate lures. You can pour or inject it into a detailed mold cavity, apply heat, and get a perfect replica. Its key properties for lure makers include:

- Adjustable Hardness (Softness): By varying the ratio of plasticizer to PVC resin, you can produce lures ranging from super-soft and wiggly to firm and durable. This is the first step in customizing your best plastisol for lures.

- Excellent Flow Characteristics: A good quality Plastisol flows easily into every minute detail of a mold, capturing delicate gill plates, leg segments, and tail textures that are crucial for realism.

- Clarity and Colorability: Many Plastisols start with a transparent or translucent base, making them perfect for creating clear, sparkle-infused, or deeply saturated colors. Learning how to color plastisol effectively is an art in itself.

Customizing Your Plastisol: Hardness, Color, and Additives

This is where you develop your signature baits. A generic Plastisol gets you started, but a tailored one builds your brand.

- Hardness Adjustment: Industry practice indicates that most lure producers keep different hardness grades on hand. A softer formula (like 10-15 Shore A) is perfect for subtle paddle tails or swimming appendages, while a harder one (20-25 Shore A) is better for creature baits or craws that need to hold their shape. You can blend them to hit the exact “chew” you want.

- Mastering Color: Whether you’re wondering how to mix plastisol ink or use powdered pigments, the key is dispersion and temperature stability. Liquid colorants are generally easier to mix evenly. We advise that you always do small test batches to see how colors cure. A common challenge is color shift—a bright orange curing into a dull brown if the temperature is off.

- Going the Extra Mile: Scents and Salt: To make your lures truly effective, you can add attractants like amino-acid-based scents or suspend salt within the Plastisol matrix. Salt adds weight for casting and gives the lure a slightly different sink rate and feel. Importantly, these additives can affect viscosity and may require slight adjustments to your process.

Injection Molding Plastisol: The Critical Parameters

This is where knowledge turns into product. Improper molding can ruin even the best soft plastic lure making material. Let’s break down the key factors.

- Temperature is King: The single most important factor is hitting the correct injection molding temperature for Plastisol. Unlike other plastics like polycarbonate or polystyrene, Plastisol doesn’t just melt; it undergoes gelation and fusion.

- Under-heating results in a tacky, weak lure that tears easily (incomplete fusion).

- Over-heating causes burning, discoloration (“scorching”), and releases toxic fumes. A precise, reliable temperature controller on your injection cylinder and molds is non-negotiable.

- Cycle Time and Cooling: Once injected into the hot mold, the Plastisol needs enough time to fully cure. Typically, this is a matter of tens of seconds. The mold then opens, and the lures are often dropped into a water bath or onto a cooling conveyor to set their shape. Optimizing this cycle is key to productivity.

- Avoiding Burned Material: Scorched Plastisol is a common headache. It can happen from material stagnating in a hot barrel or from hot spots in the mold. We recommend using a “low-bleed” or “no-bleed” Plastisol formulation for complex, multi-cavity molds, as they are more thermally stable. Furthermore, purging your machine barrel regularly is essential maintenance.

Material Selection Guide for Popular Bait Types

Not all lures are created equal, and your soft plastic lure making supplies should reflect that. Here’s our practical advice:

- Shrimp & Small Crustaceans: These often benefit from a medium-soft formulation. You want the legs and antennae to have a lifelike flutter. Good clarity in the material can help with realistic translucent effects. A high-gloss mold finish complements this.

- Crawfish/Craw Baits: Durability is key here, as these baits are often hopped along rocky bottoms. A slightly firmer Plastisol helps the claws and body maintain their shape. Adding salt can improve their bottom-scuttling action.

- Worms, Grubs, and Creature Baits: This category varies widely. A super-soft tail on a worm requires a different blend than the firm body. This is where having a versatile material system and molds designed for two-shot or overmolding (a more advanced technique) can be a huge advantage.

Case Study: Delivering Precision for a U.S. Tackle Innovator

Customer feedback suggests that tangible proof is what seals the deal for procurement teams. Let us share a recent collaboration.

Client: A fast-growing sportfishing tackle company based in Florida, USA.

Challenge: They had a brilliant new design for a hyper-realistic shrimp lure but struggled with their previous supplier. The prototypes from existing molds had poor detail definition, inconsistent filling, and high flash (excess material). This led to a high reject rate, slowing down their product launch and increasing their effective cost per unit significantly.

Our Solution: DTG TECH was engaged to redesign and manufacture a new, high-precision 8-cavity aluminum mold for their shrimp. Our engineers performed a thorough DFM (Design for Manufacturability) analysis, optimizing the gate locations and venting system specifically for their chosen plastisol for lures viscosity. We also advised them on a slightly adjusted injection molding temperature for plastisol to achieve perfect fill without burning.

The Result: The new mold produced lures with crisp, flawless detail consistently. The reduced flash meant minimal post-production trimming. Most importantly, the client reported that their production efficiency increased by over 40%, their material waste dropped, and they were able to launch their product two weeks ahead of schedule. Their procurement manager specifically noted that the total cost of ownership of the mold was lower due to its durability and the reduction in downstream labor costs.

Frequently Asked Questions (FAQ)

Q: Where is the best place to buy plastisol for lures?

A: The best plastisol for lures depends on your volume and location. Large chemical distributors supply bulk raw materials, while many specialized tackle-making suppliers offer pre-blended, lure-ready Plastisol in smaller quantities. For those searching “where to buy plastisol for lures near me” or “where to buy plastisol for lures australia“, we recommend searching for regional distributors of PVC plastisols to save on shipping costs.

Q: How different is coloring Plastisol from coloring something like Plasti Dip?

A: The principle is similar, but the formulations differ. How to color plasti dip often involves specific compatible dyes. For Plastisol, you must use heat-stable pigments designed for PVC. Using the wrong colorant can cause curing issues or fade. Always test!

Q: Why is temperature control so much more critical for Plastisol than for other plastics?

A: Materials like polypropylene or polycarbonate have a melt temperature range. Plastisol undergoes a chemical change (fusion). Think of it like cooking an egg—there’s a narrow window between perfectly cooked and burned. Precise control over the injection molding temperature for plastisol is the difference between a premium product and scrap.

Q: Can you help us develop a custom Plastisol formula for our new lure line?

A: Absolutely. While we are experts in mold making and injection molding, part of our product analysis service often involves collaborating with material suppliers and conducting trial runs to find the perfect material and process parameters for your specific design. This integrated approach ensures your product is optimized for performance and manufacturability from the start.

Conclusion & Best Practices

We can conclude that mastery of plastisol for lures is a powerful competitive advantage. Start with a high-quality base material from a reliable supplier. Invest time in developing and documenting your custom blends for hardness and color. Most importantly, respect the process parameters—temperature control is not an area for compromise.

Ultimately, the perfect lure is a synergy of three things: an ingenious design, a perfectly tuned material, and a precision-engineered mold that brings them together reliably. At DTG TECH, we specialize in that critical third component. We don’t just sell molds; we deliver manufacturing solutions that are engineered for your specific material and production goals, helping you ensure quality, meet deadlines, and improve your overall cost-effectiveness.

Ready to Translate Your Perfect Plastisol Formula into Perfect Lures?

Every great material needs a great mold to realize its potential. If you’re looking for a partner to create high-precision, durable, and production-optimized molds for your soft plastic lure line, look no further.

Explore our specialized Soft Plastic Injection Molds here or contact our engineering team today for a consultation. Let’s discuss how we can help you produce lures that look better, last longer, and perform consistently—batch after batch.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|