5 Common Injection Molding Defects in Soft Plastic Lures (and How to Fix Them)

For any brand or manufacturer in the fishing tackle industry, consistent quality isn’t just a goal—it’s the bedrock of your reputation and profitability. Every defective lure that comes off the line represents wasted material, labor, and, most importantly, a potential blow to your brand’s credibility with anglers. Soft plastic lure defects like mold flashing, bubbles, and tears are more than annoyances; they are costly symptoms of deeper issues in the manufacturing process.

At DTG TECH, we’ve spent years partnering with tackle companies worldwide, and in our experience, the majority of recurring production defects can be traced back to the mold itself or the process it enables. This guide will walk you through the five most common defects, explain their root causes from a mold-maker’s perspective, and outline the engineering solutions that prevent them for good. Ultimately, investing in precision tooling and process expertise is the most effective way to reduce your total cost of ownership and protect your brand.

1. Mold Flashing: The Unwanted “Fins” on Your Lures

Mold flashing (often called “flash”) is that thin, web-like layer of excess plastic that forms along the parting line or around ejector pins[citation:3]. In soft plastic lures, it’s especially common on complex shapes like crawfish claws or the seams of creature baits. Not only does it look unprofessional, but it also creates a weak point that can lead to how to prevent lure tearing during a fish’s fight.

Root Causes: Flashing occurs when molten plastisol finds a gap to squeeze into[citation:4]. The primary culprits are insufficient clamp force on the machine, worn-out or poorly fitting mold components, or a parting line that hasn’t been machined to a perfect seal[citation:3][citation:8]. In soft bait molds, wear from abrasive plastisol compounds accelerates this issue.

Our Engineering Solution: Prevention starts with the mold. We build our soft plastic injection molds with high-precision CNC machining to ensure parting surfaces meet with exceptional accuracy. We use hardened steels in high-wear areas and perform rigorous trial runs to confirm the mold seals perfectly under production clamp forces. This demonstrates that a robust mold design is the first line of defense against flash.

2. Bubbles & Voids: The Hidden Weakness

Nothing frustrates a lure maker more than seeing bubbles in plastisol lure bodies or internal voids. These defects weaken the structural integrity of the bait, often causing it to tear easily or creating unsightly surface blemishes[citation:3].

Root Causes: Bubbles are typically trapped air or moisture. Poor venting in the mold cavity is a major cause—if air can’t escape as the material flows in, it gets compressed and trapped[citation:3][citation:8]. Moisture in the plastisol (from improper storage or mixing) can also vaporize under heat, creating bubbles[citation:4].

Our Engineering Solution: We engineer scientifically placed and sized venting channels into our molds. This is not guesswork; it’s based on flow simulation and experience to ensure air is efficiently evacuated from deep, complex cavities like those for a soft plastic lure. Furthermore, we can advise on material handling best practices to prevent moisture-related issues, giving you a complete solution for how to get bubbles out of plastisol permanently[citation:8].

3. Lure Tearing & Poor Hook Hold

When a lure’s appendage tears off on the cast or the hook pulls out too easily, it’s a direct path to a disappointed customer. This critical failure mode is exactly what procurement teams want to know how to prevent.

Root Causes: This defect is often a combination of material formulation and gate design. A gate that is too small or in the wrong location can cause excessive shear and stress concentration in the plastisol, weakening that area[citation:3]. Similarly, a gate that leaves a large, brittle vestige at a critical stress point (like near a hook hanger) creates a natural tear point.

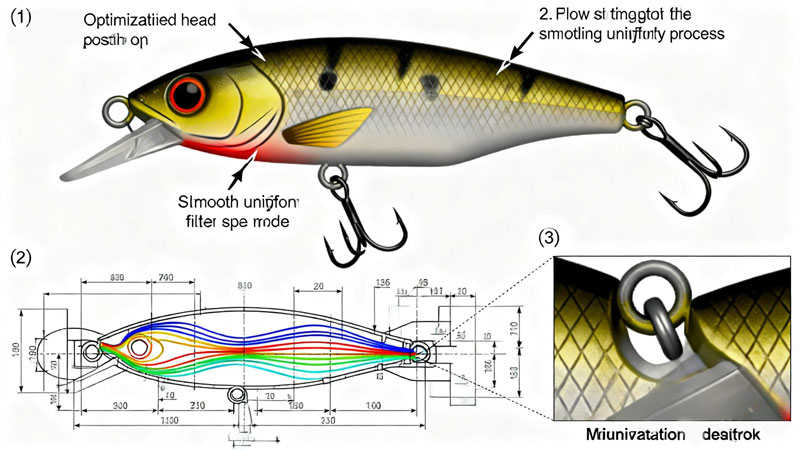

Our Engineering Solution: Our mold design service includes advanced Moldflow analysis to simulate material flow and identify stress points before steel is cut. We optimize gate location, size, and type (e.g., submarine gates) to ensure smooth filling and minimize stress. The goal is to place the gate where it ensures strength and leaves the least noticeable mark, resulting in a more durable and reliable final product.

4. Loss of Detail: When Realism Fades

The selling point of a premium soft plastic lure is its lifelike detail—the individual segments of a crawdad’s tail, the gill plates on a shad. When these details appear blurry or incomplete, the lure loses its effectiveness and perceived value.

Root Causes: Blurred details are usually a direct result of the mold’s surface finish or its ability to be filled completely. A poorly polished cavity, microscopic tooling marks, or inadequate venting (which prevents the material from pressing into the finest textures) can all rob your design of its sharpness.

Our Engineering Solution: We employ a multi-step finishing process. After high-precision machining, cavities undergo hand-polishing to a mirror finish or precise texturing to match your specification. Coupled with our optimized venting and injection process guidance, this guarantees that every scale, leg, and antenna on your soft plastic lure types is reproduced with stunning, consistent clarity.

5. Short Mold Life: The Cycle of Replacement

Perhaps the most significant cost advantage we offer is extending the life of your tooling. Constantly repairing or replacing molds that are worn down by abrasive plastisol, salt additives, or corrosion is a major, unpredictable expense.

Root Causes: Standard mold steels can degrade quickly when exposed to the chemicals and abrasives in soft plastic formulations. This wear leads to increased flashing, loss of detail, and eventually, mold failure.

Our Engineering Solution: We select materials engineered for the job. For high-volume production, we recommend and use premium corrosion-resistant steels like Stavax or hardened steels like H13. These materials withstand abrasive plastisols far longer than standard options. We advise that this upfront investment in superior tool steel dramatically reduces your cost-per-part over the mold’s lifetime and ensures consistent quality for hundreds of thousands of cycles.

Case Study: Solving Chronic Flashing for a U.S. Tackle Brand

Client: A established fishing tackle manufacturer in Texas, USA.

Challenge: They were experiencing chronic and worsening mold flashing on their flagship craw lure, leading to a 15% rejection rate and costly manual trimming. Their existing mold, from a different supplier, was less than two years old but could not maintain a clean parting line.

Our Solution: DTG TECH conducted a full audit of the old mold and the production process. We identified wear on the parting line and suboptimal clamp force settings. We manufactured a new, identical craw mold cavity using hardened H13 steel and achieved a superior surface fit. We also provided the client with precise machine parameters for their presses.

The Result: The new mold eliminated flashing entirely. The client’s rejection rate dropped to near zero, and their post-processing labor costs were significantly reduced. Their Production Manager noted, “The quality and consistency from the DTG mold have not wavered. The delivery was on schedule, and the total cost saved in waste and labor paid for the new tooling in under eight months.”

Frequently Asked Questions (FAQ)

Q: Can’t we just fix these defects by adjusting the injection machine settings?

A: While process tuning can help mitigate some issues, it’s often a temporary fix for a hardware problem. Industry practice indicates that chronic defects like flashing or short shots are usually rooted in mold design or wear[citation:7]. Optimizing the process around a flawed mold limits your efficiency and can create other defects. The most reliable long-term solution is a well-engineered mold paired with a stable process.

Q: How does your ISO certification translate to better mold quality for us?

A: Our ISO-certified quality management system ensures every step—from design review to final inspection—is documented and controlled. This systematic approach guarantees that every mold meets precise specifications consistently, reducing the risk of errors that lead to defects and ensuring reliable performance for your production team.

Q: We have a unique, complex lure design. Can you handle it?

A: Absolutely. Our expertise in prototyping and complex mold manufacturing is why innovators partner with us. We use advanced 3D scanning, CAD design, and multi-axis CNC machining to create molds for geometries that other shops might avoid, ensuring even your most intricate designs are produced flawlessly.

Conclusion & Call to Action

We can conclude that the pursuit of perfect soft plastic lures is won or lost at the mold level. Addressing soft plastic lure defects requires more than quick fixes; it demands a partnership with a manufacturer who understands the intricate relationship between mold geometry, material science, and production dynamics.

At DTG TECH, we don’t just sell molds; we deliver manufacturing solutions. Our focus on precision engineering, durable materials, and deep process knowledge is designed to give you a cost-effective advantage: fewer defects, less waste, longer tool life, and a stronger brand reputation.

Ready to eliminate defects at the source and build a more reliable, profitable production line?

Explore our Soft Plastic Injection Mold portfolio to see our capabilities, or contact our engineering team today for a confidential discussion about your specific challenges and goals.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|