Xiamen DTG Tech CO., Ltd (DTG)

Founded in 2002 and headquartered in Xiamen, China, Xiamen DTG Tech Co., Ltd (DTG) specializes in providing one-stop mold and injection molding solutions. Focused on innovative technology and high-quality services, we cover multiple industries including industrial product design, prototyping, mold design, plastic injection molding, assembly, and packaging development. Over more than 23 years of steady growth, DTG has become a leading manufacturer both domestically and internationally, with strong technical expertise and production capabilities. The company holds ISO 9001:2015 certified, ensuring that all products and services comply with international standards, while consistently prioritizing quality and providing clients with comprehensive solutions from product development and manufacturing to after-sales support.

our history

A timeline that captures our journey of growth, innovation, and continuous progress.

Present

DTG employs 80 staff, operates a 2,500 m² facility, and boasts comprehensive technical capabilities. We now offer one-stop solutions spanning product design, mold design and manufacturing, prototyping, product analysis, injection molding, 3D printing, assembly, and packaging.

2019

Obtained ISO 9001 quality management system certification to further enhance management standards and product consistency.

2015

Established an international trade subsidiary to serve global clients with high-quality products and services.

2005

Expanded its operations by introducing advanced mold processing equipment, thereby improving production capacity and product precision.

2002

Founded in Xiamen with only six employees and basic mold design and injection molding equipment, DTG initially focused on mold manufacturing and small-batch production.

Leadership Team

Project Director Mr. Leo Liu brings over two decades of expertise in product design, mold engineering, injection molding, and project management.

He has held key roles at leading companies including Omni Mold (Singapore), Sunningdale Tech, and Becton Dickinson, where he spearheaded the development of precision plastic components for global clients such as HP, Dell, and Apple.

Under his leadership, DTG consistently advances technical standards, streamlines production processes, and ensures that every project meets the highest quality and on-time delivery expectations.

Discover more about his professional achievements on LinkedIn.

Core Services

Product & Mold Design Engineering: Transforming clients’ ideas into efficient, manufacturable mold solutions through optimized structural and manufacturability analysis.

Rapid Prototyping: Delivering high-precision prototypes to support functional testing, market validation, and design iterations—shortening development cycles and reducing upfront investment risks.

Industrial 3D Printing: Leveraging advanced 3D printing technologies for the rapid formation of complex parts and small-batch production, meeting agile development and customization requirements.

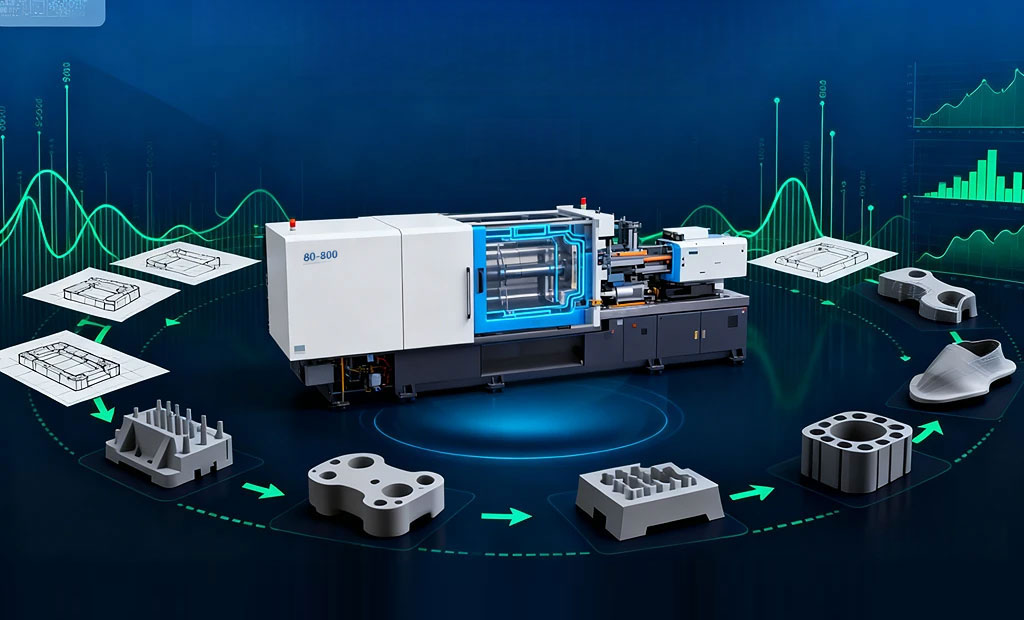

Plastic Injection Molding: Equipped with machines ranging from 80 to 800 tons, we specialize in processing various engineering plastics and two-color molding, capable of manufacturing everything from tiny components to large housings.

Die Casting: Providing zinc and aluminum die-cast parts and mold solutions for the home appliance, automotive, and lighting industries—offering excellent strength, precision, and durability.

Secondary Processing & Assembly: Delivering post-processing services such as painting, silk-screening, and ultrasonic welding, ensuring products are delivered fully assembled.

Plastic Blow Molding: Specializing in hollow plastic products (e.g., bottles, containers, and industrial parts) for the packaging, medical, and consumer goods sectors.

Equipment & Capabilities

DTG continuously upgrades its facilities, evolving from basic equipment to modern production lines:

Injection Molding Machines: Multiple units ranging from 80T to 800T

Wire EDM Machines: 4 units

Milling Machines: 7 units

Grinding Machines: 4 units

CNC Machining Centers: 7 units

3D Printing Equipment: EOS, SLS PERFORMANCE, HP MJF 5210, DM POLYSHOT S

Other Equipment: Sink EDM Machines, additional CNC machining equipment, etc.

Quality & Certification

DTG holds ISO 9001:2015 certification, ensuring all products comply with international standards. Rigorous production control guarantees safe, reliable products for global clients.

Selected Authorized Projects & Cases

High-Precision LED Optical Lens: 98% light transmittance, ±0.02 mm flatness, and 500,000 defect-free units delivered on time.

Dynamic Bicycle Chain Cover: Optimized molding process with sample approval and mass production completed in 3 days.

Large Vortex Fountain Assembly: Transparent and black components featuring precision molding, high transparency, and superior gloss.

Flame-Retardant Automotive Lamp Holder: Manufactured with S136 steel (HRC 48-52) and a mold service life of 500,000 cycles.

Custom Silver Doorbell Camera Housing: ABS+PC material with a brushed and vacuum-plated high-gloss finish.

Food-Grade PS Clear Water Bottles: Produced in a Class 100,000 cleanroom with UV sterilization post-packaging.

Flame-Retardant TPE Gaskets: Shock absorption, sealing performance, and V0 flame rating.

PC+ABS Projector Housing: Hybrid material with a high-quality surface finish.

Custom Food Containers: Full-process development from industrial design to mass production.

Vision & Mission

DTG upholds the principle of “Quality First, Customer First,” dedicating itself to excellence in mold design, mold manufacturing, and injection molding solutions. We continuously invest in technological innovation and process optimization to deliver high-quality, cost-effective products to clients worldwide. Having grown from a small startup with only six employees, we understand that every great idea begins with small steps—whether it’s small production volumes, early-stage designs, limited budgets, or uncertainty about how to move forward. That’s why we welcome projects of any size and provide professional guidance, reliable engineering support, and dedicated service from prototyping to mass production. At DTG, no project is too small, and every customer deserves a partner who takes their product seriously.