Trusted Excellence in Electronic Component Injection Molding

At DTG, we take pride in being a global leader in Electronic Component Injection Molding, delivering Customized On Demand manufacturing solutions that meet the highest standards of quality, precision, and innovation. Our expertise spans across a wide range of electronic applications — from miniature micro-connectors and protective casings to high-performance enclosures and insulation components used in critical electronic systems.

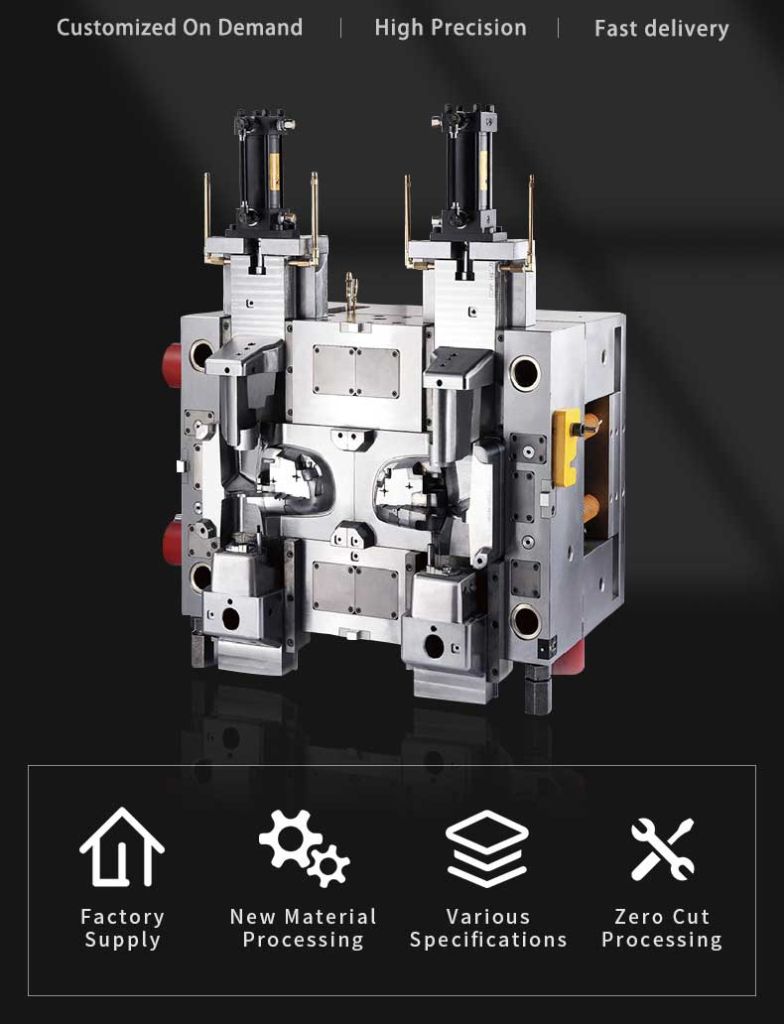

With advanced High Precision molding equipment and Zero Cut Processing technology, every component we produce is engineered with meticulous accuracy and repeatable consistency. Our New Material Processing capabilities allow us to handle a variety of advanced polymers and high-performance materials, ensuring that each part meets stringent electrical, thermal, and mechanical performance requirements.

Through our robust Factory Supply system, DTG delivers efficient, scalable production supported by rigorous quality control at every step — from raw material selection to final inspection. Our Fast Delivery service ensures customers receive precision-molded components on time, maintaining smooth production cycles and reducing downtime. We also offer Various Specifications and full customization options, allowing our clients to develop unique components that fit their specific product designs and regulatory standards.

At DTG, we believe that true excellence comes from combining technical expertise, cutting-edge manufacturing, and a deep understanding of our clients’ needs. Partner with us to create high-quality Electronic Component Injection Molding solutions that enhance reliability, boost performance, and drive innovation throughout the global electronics industry. Together, we build the foundation for smarter, stronger, and more efficient electronic products.

Injection Molding Manufacturing in Electronic Products

- Shells and appearance parts: Injection molding is often used to produce shells and appearance parts of electronic products, such as mobile phone cases, tablet cases, keyboards, mice, etc. These appearance parts usually require high precision, beautiful appearance and good feel. Injection molding technology can achieve complex designs and fine surface treatments to meet the appearance requirements of electronic products.

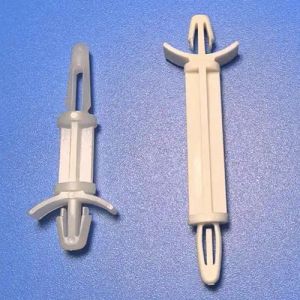

- Connectors and sockets: Connectors, sockets and terminals in electronic products are also often produced using injection molding technology. These parts usually require high precision, reliability and durability, and injection molding technology enables precise mold design and efficient production to meet the connection needs of electronic products.

- Electronic accessories and components: Injection molding is widely used to produce various electronic accessories and components, such as battery compartments, circuit board brackets, electronic slots, etc. These accessories and components often require specific shapes, sizes and material properties, and injection molding technology can meet a variety of complex shapes and precision dimensions.

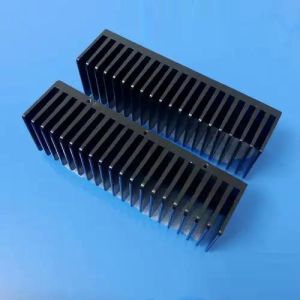

- Heat sinks and heat insulation parts: In some high-performance electronic products, injection molding is used to produce heat sinks and heat insulation parts, such as heat sinks, cooling fan casings, heat shields, etc. These parts usually need to have good thermal conductivity, insulation and high temperature resistance, and injection molding technology can achieve complex heat dissipation structures and precise heat insulation designs.

- Electronic product packaging: Injection molding is also commonly used to produce packaging materials for electronic products, such as plastic boxes, protective covers, packaging boxes, etc. These packaging materials usually need to have good transparency, toughness and impact resistance. Injection molding technology can realize packaging designs of various shapes and sizes to protect electronic products from damage.

Common Electronic Component Applications

Injection molding manufacturing has a wide range of applications in the electronics field, providing an efficient, accurate and cost-effective solution for producing all types of electronic products.

Why Choose DTG Injection Molding Services ?

ISO Certified

ISO Certified

Expertise

Advanced Equipment

Fast delivery

Customer Focus

Our Mold Design Process

For simple parts, product lead times can be reduced to as little as 3 days.Upload your part to see if it qualifies.

01

Requirement Analysis

We start by thoroughly understanding the project requirements, including the part geometry, material properties, production volume, and budget constraints. This initial phase involves close collaboration with the client to gather all necessary information and establish clear design objectives.

02

Conceptual Design

Our team of skilled designers and engineers utilizes advanced CAD software to create conceptual designs based on the project requirements. This phase involves brainstorming innovative solutions and exploring various design options to achieve the desired functionality and manufacturability.

03

Detailed Design

Once the conceptual design is approved, we proceed to the detailed design phase. This stage involves refining the 3D model to incorporate all essential features, such as parting lines, gating systems, cooling channels, and ejection mechanisms. Our designers pay meticulous attention to detail to optimize the mold design for efficiency and performance.04

Simulation & Analysis

Once the conceptual design is approved, we proceed to the detailed design phase. This stage involves refining the 3D model to incorporate all essential features, such as parting lines, gating systems, cooling channels, and ejection mechanisms. Our designers pay meticulous attention to detail to optimize the mold design for efficiency and performance.

05

Design Review & Optimization

The design undergoes thorough review by our team of experts, where potential issues or areas for improvement are identified and addressed. We collaborate closely with the client to incorporate feedback and make any necessary adjustments to optimize the mold design for manufacturability and functionality.

06

Prototype Development

Upon finalizing the design, we proceed to prototype development to validate the mold’s functionality and performance. This stage involves manufacturing prototype molds and conducting rigorous testing to ensure they meet the client’s requirements and quality standards.

07

Finalization & Production Release

Once the prototypes are successfully tested and approved by the client, we finalize the mold design and release it for full-scale production. Our team closely monitors the manufacturing process to ensure the molds are fabricated to the highest standards and deliver consistent, high-quality parts.

08

Continuous Improvement

At Omni, we are committed to continuous improvement and innovation. We regularly evaluate our mold design process to incorporate the latest technologies, best practices, and customer feedback, ensuring we deliver exceptional results with every project.