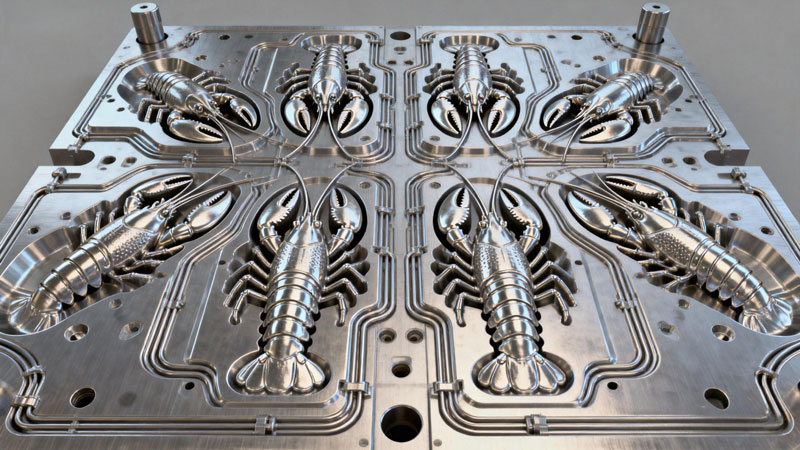

Case Study: How Aollerfilery Scaled Production with Our Multi-Cavity Crawfish Mold

Scaling a successful fishing lure brand from a passionate startup to a dominant market player requires more than great designs—it demands industrial-grade manufacturing capability. This is the story of how Aollerfilery, an innovative soft plastic lure company from Florida, USA, transformed their lure production and captured new market share by partnering with DTG TECH. Their journey from a bottlenecked, single-cavity process to streamlined, high volume lure production perfectly illustrates the transformative power of precision tooling. Ultimately, this soft plastic mold case study demonstrates how the right partnership can turn production constraints into a competitive advantage.

The Client: A Brand Hitting a Production Ceiling

Aollerfilery had developed a cult following among bass anglers for their incredibly realistic and effective crawfish bait. The design was a winner, but their manufacturing process was holding them back. They relied on simple, single-cavity molds for how to make plastic bait molds at a small scale. This method created a severe bottleneck.

Their core challenges were clear:

- Crippling Low Output: Producing lures one at a time made it impossible to meet growing distributor demand or run cost-effective large batches.

- Inconsistent Quality: Manual processes and basic molds led to variations in detail clarity and weight, which is critical for consistent lure action.

- Missed Opportunities: The inability to scale reliably prevented them from launching into larger retail chains or fulfilling major seasonal orders on time.

In our view, this is a classic growth pain for successful brands. The passion and product-market fit are there, but the production infrastructure hasn’t evolved to match the business ambition.

The Challenge: Engineering a Scalable, High-Performance Solution

Aollerfilery came to us with a specific and demanding goal: they needed a mold that could at least quintuple their output without sacrificing the intricate detail that made their crawfish so special. They weren’t just looking for a multi cavity bait mold; they needed a high performance manufacturing tool engineered for their specific, complex geometry.

The technical hurdles were significant. The crawfish design had deep, undercut claws and fine antennae that are notoriously difficult to eject from a multi-cavity soft plastic mold without tearing. Industry experience shows that simply copying a single-cavity design into multiple cavities often leads to filling imbalances and defective parts. They needed a partner who understood both soft plastic mold making and high-volume production dynamics.

Our Collaborative Solution: Precision from Design to Delivery

Our engagement began with a comprehensive design evaluation. We didn’t just take their CAD file and start cutting metal. Our engineers performed a detailed DFM (Design for Manufacturability) analysis, focusing on the challenges unique to high-volume productions.

The three pillars of our solution were:

- Optimized Multi-Cavity Design: We proposed a balanced 6-cavity layout. This wasn’t an arbitrary number; it was calculated to maximize output on their existing injection molding machines while ensuring perfect, even fill across all cavities. We optimized the gate locations and runner system to ensure each lure received material at the same pressure and temperature.

- Advanced Engineering for Complex Geometry: To solve the ejection problem with the claws and antennae, we meticulously adjusted draft angles and designed a custom, multi-stage ejection system. This guaranteed that even the most delicate parts of the lure would release cleanly and consistently, cycle after cycle, which is critical to how to prevent lure tearing during the molding process itself.

- Durable Tooling for Long-Term Value: Understanding the abrasive nature of plastisol and the demand for high volume runs, we manufactured the cavity inserts from hardened NAK80 steel. This premium material offers superior polishability for detail and excellent wear resistance, extending the mold’s life far beyond standard aluminum or soft steel—a key factor in achieving a lower total cost of ownership.

Throughout the mold manufacturing process, we provided regular progress reports. Importantly, we maintained clear, proactive communication in English, ensuring their team was always informed—a critical factor for smooth project management with overseas partners.

The Remarkable Results: A 500% Leap in Production Capacity

The impact of the new mold was immediate and transformative for Aollerfilery’s operations.

- Production Output Skyrocketed: They achieved a 500% increase in production efficiency. What used to take five hours now took one. This directly translated to the ability to accept larger orders and reduce lead times for customers.

- Unmatched Consistency and Quality: Every single lure from the 6-cavity mold was identical. The detail on the shell texture and claws was sharper than ever before, enhancing the product’s realism. This demonstrates that high volume and high quality are not mutually exclusive with the right tooling.

- Significant Cost Per Unit Reduction: The dramatic increase in output, combined with reduced labor and machine time per lure, slashed their overall manufacturing cost. This gave them greater pricing flexibility and improved profitability.

In Their Own Words: Aollerfilery’s Testimonial

“Partnering with DTG TECH was the strategic decision that allowed our brand to graduate to the next level. We were hesitant about moving production overseas, but their ISO-certified process and professional communication put us at ease. The mold arrived on schedule and performed flawlessly from the first test shot. The quality of the lures it produces is exceptional—the detail is even better than our original prototypes. This tool hasn’t just increased our capacity; it has given us the reliability to build stronger relationships with our retailers. The cost advantage and speed we gained have been fundamental to our recent growth.”

– Michael R., Chief Operations Officer, Aollerfilery

Frequently Asked Questions (FAQ)

Q: Is a multi-cavity mold only suitable for huge companies?

A: Not at all. We recommend that any brand planning for growth or producing a best-selling item consider a multi-cavity solution. The efficiency gains quickly offset the initial tooling investment. We work with companies of all sizes, providing tailored solutions that match their current machine capabilities and future goals.

Q: How do you ensure a multi-cavity mold will work with our specific injection molding machine?

A: This is a crucial part of our design process. Before finalizing the mold design, we review your machine’s specifications—clamp tonnage, shot size, platen size, etc. We engineer the mold to operate reliably within your machine’s parameters, ensuring a seamless integration into your existing production line.

Q: What about the lead time for a complex mold like this?

A: For a 6-cavity steel mold of this complexity, a typical lead time is 5-7 weeks. In our experience, clear communication and a finalized design upfront are key to maintaining schedule. We provide a detailed project timeline from the outset and stick to it with disciplined project management, a core part of our ISO-certified service promise.

Conclusion: Scale Your Success with Confidence

We can conclude that the bridge between a great product and a great business is often built on precision manufacturing. Aollerfilery’s story is a powerful example of how strategic investment in professional tooling unlocks scalability, consistency, and profitability.

At DTG TECH, we specialize in being that bridge for ambitious brands. Our expertise in creating high-performance, multi-cavity bait molds is backed by a commitment to quality, on-time delivery, and a partnership approach that reduces your total cost and risk.

Ready to Transform Your Production?

Does your brand face similar bottlenecks? Are you ready to transition from slow, manual methods to efficient, high-volume lure production?

Your success story starts with a conversation. Our engineering team is ready to analyze your specific needs and provide a solution that will help you scale with confidence.

Explore Our Soft Plastic Injection Mold Portfolio

or

Contact Us Directly for a Free Project Consultation

Let’s discuss how a custom, high-precision mold can become the engine for your brand’s next phase of growth.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|