Home » Case Products » Multi Shot Plastic Injection Molding

Multi Shot Plastic Injection Molding

We specialize in producing high-quality, complex plastic components with multiple materials or colors in a single molding cycle. Our advanced multi-shot molding technology enables us to achieve precise geometries, intricate designs, and superior functionality, catering to diverse industry needs.

Our Expertise:

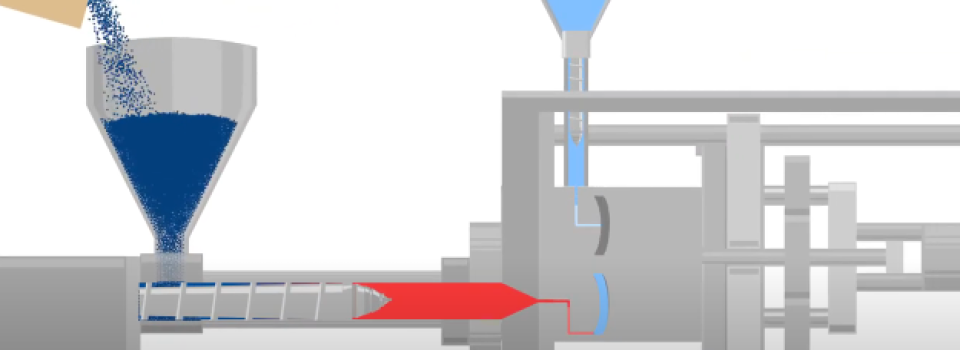

- Advanced Technology: We leverage state-of-the-art multi-shot injection molding machines equipped with rotating or indexing molds to produce parts with multiple materials or colors in one seamless process.

- Material Compatibility: Our extensive knowledge of various thermoplastics allows us to combine compatible materials with different properties, such as hardness, flexibility, and transparency, to meet your specific requirements.

- Design Optimization: Our experienced engineering team collaborates closely with clients to optimize part design for multi-shot molding, ensuring seamless material transitions, minimal waste, and enhanced part performance.

Key Features:

- Multiple Materials: Our multi-shot molding capabilities allow us to integrate different materials, such as rigid and flexible plastics, elastomers, or even metal inserts, within a single part, expanding design possibilities and functionality.

- Color Variation: We can achieve precise color matching and intricate color patterns by injecting different pigments or dyes into designated areas of the mold, enhancing aesthetics and brand identity.

- Complex Geometries: Multi-shot molding enables the production of parts with complex geometries, including overmolded grips, soft-touch surfaces, and integrated seals, without the need for secondary assembly processes.

Applications:

Our Multi-Shot Plastic Injection Molding solutions find applications across various industries, including:

- Automotive: Interior trim components, steering wheel grips, and sensor housings with integrated seals.

- Consumer Electronics: Keyboards, remote controls, and electronic device casings with soft-touch buttons or grips.

- Medical Devices: Surgical instruments, drug delivery devices, and wearable medical devices with biocompatible overmolded components.

- Packaging: Cosmetic packaging, closures, and dispensers with custom color accents and ergonomic features.

Benefits:

- Enhanced Design Flexibility: Multi-shot molding allows for the integration of multiple materials or colors in a single part, opening up new design possibilities and enhancing product aesthetics.

- Improved Product Performance: By combining materials with complementary properties, such as rigidity and flexibility or hardness and softness, multi-shot molding can improve product functionality, durability, and user experience.

- Streamlined Production: Consolidating multiple manufacturing steps into a single molding cycle reduces lead times, assembly costs, and material waste, resulting in a more efficient and cost-effective production process.

Why Choose Us?

- Technical Expertise: With extensive experience in multi-shot injection molding, we have the knowledge, skills, and resources to tackle complex projects and deliver superior results.

- Advanced Equipment: Our state-of-the-art injection molding machines and tooling are equipped with the latest multi-shot technology, allowing us to achieve precise material placement and exceptional part quality.

- Quality Assurance: We maintain strict quality control measures throughout the manufacturing process to ensure that every multi-shot molded part meets the highest standards of performance, consistency, and reliability.

Partner with us for your multi-shot plastic injection molding needs, and let us help you bring your innovative designs to life. Contact us today to discuss your project requirements or request a quote. We look forward to collaborating with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Custom Prototypes: Tailored Solutions for Innovative Product Development

Read more -

Optimize Your Designs with Injection Molding Ribs

Read more -

Rapid CNC Prototyping: Accelerate Your Product Development with Precision Machining

Read more -

EVA Injection Molding Solutions

Read more -

Thin Wall Injection Molding

Read more -

OEM Custom Rubber PA66 Plastic Service Plastic Rapid Prototyping Parts

Read more