Your Professional Industrial Mold Manufacturer Partner

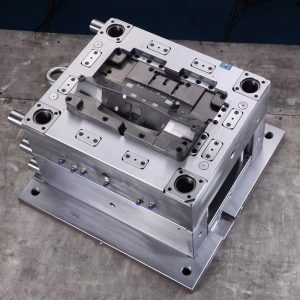

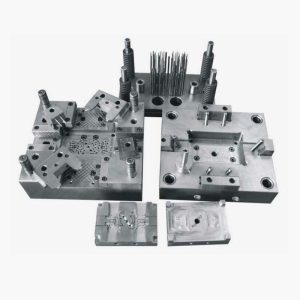

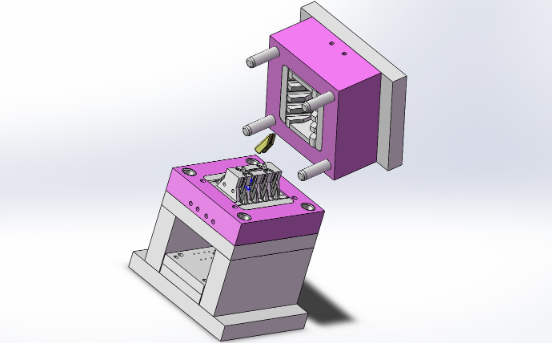

We provide high-quality, manufacturer plastic injection mold server, covering injection molding, die-casting, stamping and other industries, and are committed to providing customers with reliable and efficient mold solutions.

Our Production Workshop

DTG Cooperation Process

For simple parts, product lead times can be reduced to as little as 3 days.Upload your part to see if it qualifies.

01

Quote Phase

02

Mode Design & Creation

03

Production

04

Logistics & Delivery

Why Choose DTG Industrial Molds Services ?

ISO9001

ISO 9001:2015 | ITAR Registered | 5S - Lean Manufacturing

ISO Certified

DTG because we are an ISO9001:2015 certified manufacturer who embraces the principles of 5S management; whether you need customized design, precision manufacturing, or strict quality control, DTG can meet your needs and exceed your expectations.

Expertise

With years of experience in electronic component injection molding, we have the knowledge and skills to deliver exceptional results.

Innovation

We are dedicated to staying ahead of industry trends and technological advancements, allowing us to offer innovative solutions that meet the evolving needs of our clients.

Advanced Equipment

Equipped with the latest injection molding machines and technology, we ensure the highest level of precision and consistency in every project. From small-scale prototypes to large-scale production runs, we have the capabilities to meet your demands.

Fast delivery

We have efficient production processes and advanced equipment, which can complete orders in the shortest time and deliver them on time. We understand that time is of the essence to your business, so we are committed to providing fast and reliable delivery services.

Customer Focus

Your satisfaction is our priority. We strive to exceed your expectations at every step of the process, building lasting relationships based on trust and reliability.

Contact Us For A Injection Mold Quote

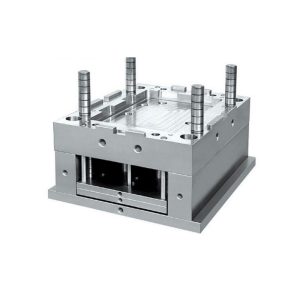

Our Equipment

Our Mold Design equipment uses the most advanced technology and facilities to provide customers with efficient and precise production solutions to meet the manufacturing needs of various complex parts.

Wire Cutting Equipment

DTG - Industrial Mold Manufacturing Services

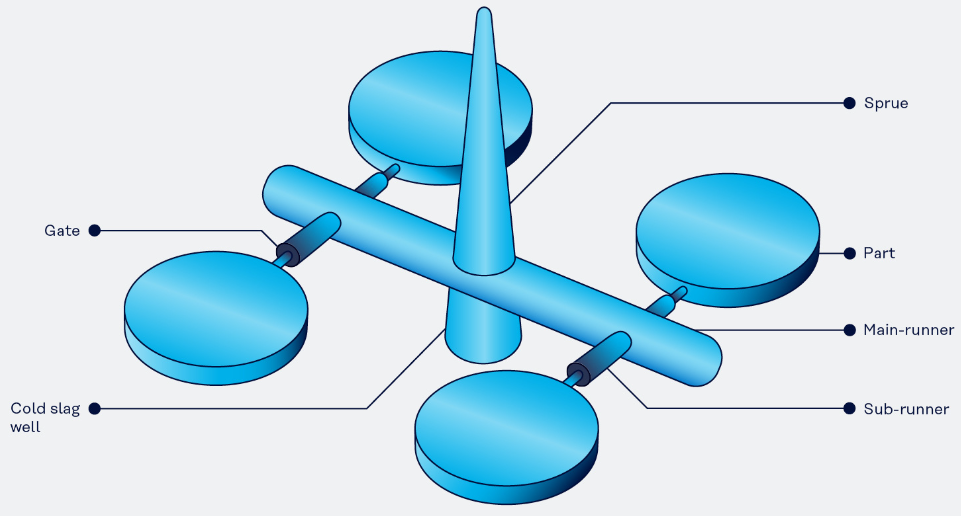

1. Molding Molds: Our products are widely used in the manufacturing of molding molds, including injection molds, die-casting molds, blow molding molds, and so on. These molds are key equipment in industrial production and are used to produce various parts and products made of plastic, metal and other materials.

2. Stamping Molds: Our products are also used in the manufacture of stamping molds, which are used to perform stamping and forming operations on sheet metal to produce various metal parts and components. These molds are highly accurate and durable to meet the processing needs of complex parts.

3. Die Casting Molds: Our products play a key role in the manufacturing of die casting molds, which are used to produce a variety of metal parts and products, such as automotive parts and industrial equipment accessories. Our molds have high precision and durability to meet the high requirements of die casting processing needs.

4. Plastic Extrusion Molds: Our products are also used in the manufacture of plastic extrusion molds, which are used to produce a variety of plastic products, such as pipes, plates, profiles and so on. Our molds have excellent fluidity and molding performance, and can achieve a variety of complex shapes of plastic products processing.

customized Manufacturing

What’s New at GTG

Unveiling Epoxy: An In-Depth Guide to Its Definition, Properties, and Applications

Epoxy, a vital thermosett