We Are Proud to Share That Our Company Is Now ISO 9001 Certified

Customer-Centric Approach

Your resource center for the plastic injection molding industry, the "DTG" blog.

Home » Blog & Articles

Customer-Centric Approach

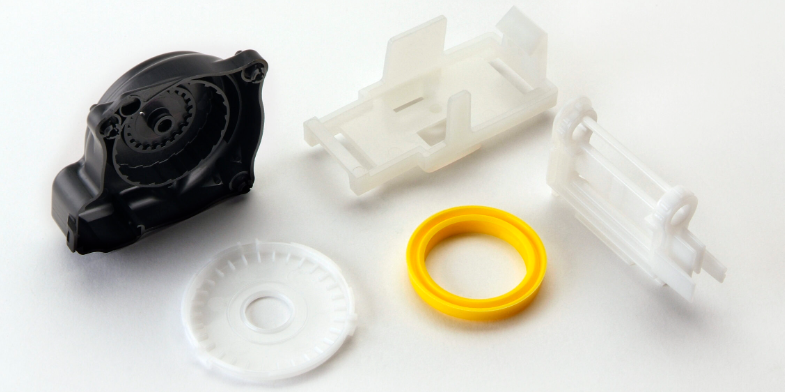

Introduction to PPE Injec

Understanding the Importa

Introduction to PPE Injec

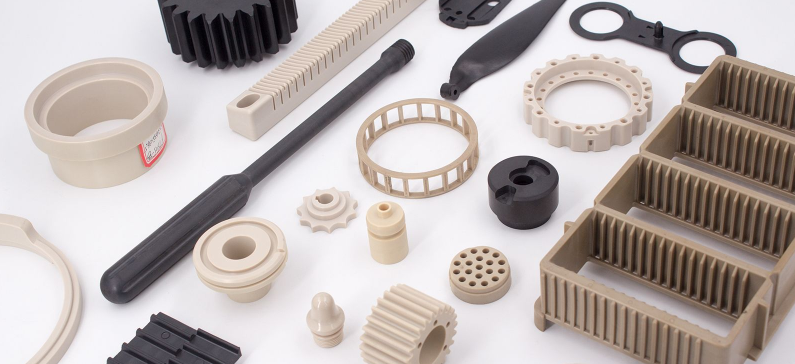

In the world of high-perf

How Does PPE Injection Mo

Why Is PPE Injection Mold

In today’s fast-evo

In the fast-evolving worl

Understanding the key ter

Hydraulic Plastic Injecti

Ensuring the safety of pl

One significant trademark

Introduction Polyethereth

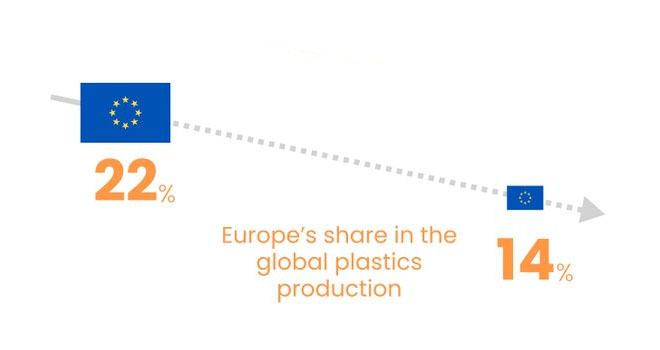

European plastics manufac

DTG TECH CO., LTD.

Room 707, Yulong International Building 1, No.987, Anling Road, Xiamen 361006, Fujian, China

Trustpilot

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

Professional injection mold manufacturing, get accurate quotation in as fast as 60 minutes!

Data Privacy And Security:

We take the privacy and security of customer data very seriously. The product data files you upload will not be used for any other purpose. They will never be forwarded, sold or shared with other third parties.