Yes, acetone can melt or dissolve certain types of plastic, depending on the material. Acetone is a powerful solvent that interacts with plastics differently based on their chemical composition. Here’s a detailed explanation:

Plastics Affected by Acetone

Some plastics are highly susceptible to acetone and can be melted, softened, or even completely dissolved upon contact. These include:

- Polystyrene (PS):

Acetone dissolves polystyrene very quickly, turning it into a gooey substance. This property is often used in demonstrations, such as dissolving Styrofoam (expanded polystyrene). - Acrylic (PMMA):

Acetone can soften or melt acrylic, leading to damage or structural weakening. - PVC (Polyvinyl Chloride):

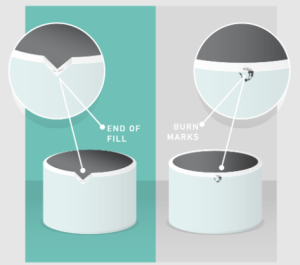

PVC can become slightly soft or deformed when exposed to acetone. - ABS (Acrylonitrile Butadiene Styrene):

ABS plastic is partially soluble in acetone and may soften or deform if exposed for extended periods.

Plastics Resistant to Acetone

Some plastics are resistant to acetone and will not melt or dissolve easily:

- Polyethylene (PE):

Commonly used in containers and plastic bags, PE is resistant to acetone. - Polypropylene (PP):

Found in bottle caps and other durable products, PP is similarly unaffected by acetone. - PTFE (Teflon):

Highly resistant to solvents, PTFE remains unchanged by acetone exposure.

Why Acetone Melts Certain Plastics

Acetone works by breaking down the polymer chains in susceptible plastics. It reduces the intermolecular forces holding the plastic together, causing it to lose its rigidity and dissolve or deform.

Applications of Acetone’s Effect on Plastic

- Cleaning:

Acetone is commonly used to remove adhesives or clean surfaces, but care must be taken to avoid damage to plastic components. - Crafting:

Acetone’s ability to dissolve polystyrene is sometimes used for DIY projects and repairs. - Recycling and Modeling:

In some cases, acetone is used to smooth or reshape 3D-printed ABS plastic objects.

Precautions When Using Acetone Around Plastics

- Test First: Always test acetone on a small, inconspicuous area of plastic to determine its effect.

- Ventilation: Use acetone in a well-ventilated area to avoid inhaling fumes.

- Avoid Extended Contact: Limit the duration of exposure to prevent unintentional melting or damage.

By understanding how acetone interacts with different plastics, you can use it effectively without risking damage to unintended surfaces.