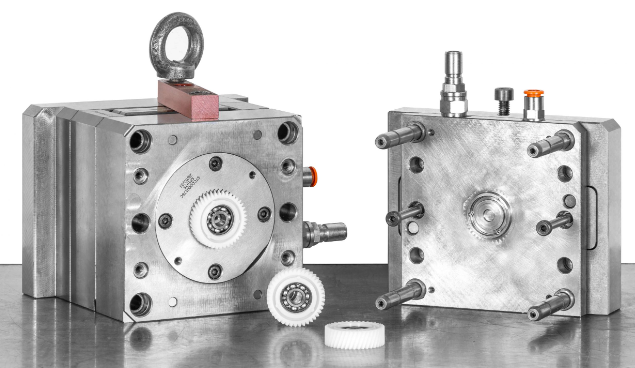

At DTG Plastic Molding, we specialize in providing custom insert injection molding solutions tailored to your specific needs. Our state-of-the-art technology and experienced team ensure high-quality production that meets the exact specifications of your project.

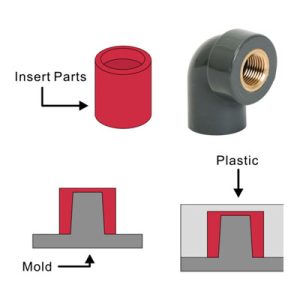

Insert injection molding is a specialized manufacturing process that combines traditional injection molding with the insertion of pre-formed components, such as metal parts or other materials, into a mold. This technique allows for the creation of complex parts with enhanced functionality, durability, and reduced assembly time.

The insert molding process involves several key steps:

This process not only streamlines production but also enhances the overall strength and integrity of the final product.

Data Privacy and Security:

We use your data files only for the purpose of product inquiry and not for any other purpose. Your data files will never be forwarded, sold or shared with other third parties.

ISO9001

ISO 9001:2015 | ITAR Registered

With years of experience in the industry, we understand the nuances of insert molding and can deliver exceptional results.

We offer Original Equipment Manufacturer (OEM) services, allowing you to create bespoke products designed to your specifications.

Our rigorous quality control processes guarantee that every part meets the highest standards of quality and performance.

Our manufacturing capabilities in China allow us to offer cost-effective solutions without compromising on quality.

01

02

03

04

If you’re looking for innovative insert molding solutions, DTG is here to help. Contact us today to discuss your project requirements, and let our team of experts guide you through the insert injection molding process. Together, we can create high-quality, durable parts that meet your specific needs.

DTG TECH CO., LTD.

Room 707, Yulong International Building 1, No.987, Anling Road, Xiamen 361006, Fujian, China

Trustpilot

Professional injection mold manufacturing, get accurate quotation in as fast as 60 minutes!

Data Privacy And Security:

We take the privacy and security of customer data very seriously. The product data files you upload will not be used for any other purpose. They will never be forwarded, sold or shared with other third parties.

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.