Rubber Injection Molding Service

Rubber molding services specialize in producing custom rubber parts using various molding techniques, ensuring durability and precision for diverse applications.

Our Rubber Molding Services

At DTG, we specialize in a wide range of rubber molding services to meet your specific needs, including:

- Custom Molded Rubber: We create tailored rubber components based on your unique specifications, ensuring a perfect fit for your application.

- Injection Mold Rubber: Our advanced injection molding process allows us to produce high-quality rubber parts that are both durable and reliable.

- Liquid Silicone Rubber Injection Molding: We offer liquid silicone rubber (LSR) injection molding services, providing flexible, heat-resistant, and biocompatible solutions for a variety of industries.

Why Choose Us as Your Rubber Molding Manufacturers?

ISO9001

ISO 9001:2015 | ITAR Registered

Expertise

Our team has extensive experience in rubber molding, ensuring we deliver high-quality solutions that meet industry standards.

State-of-the-Art Equipment

We utilize the latest technology in rubber injection molding to ensure efficiency and accuracy in every project.

Quality Assurance

Our rigorous quality control processes guarantee that all rubber components are tested for durability and performance.

Competitive Pricing

We understand the importance of timely delivery and work diligently to meet your deadlines without compromising quality.

DTG Cooperation Process

01

Quote Phase

02

Samples & Tests

03

Production

04

Logistics & Delivery

Get a Quote Today

Data Privacy and Security:

We use your data files only for the purpose of product inquiry and not for any other purpose. Your data files will never be forwarded, sold or shared with other third parties.

What is Rubber Injection Molding?

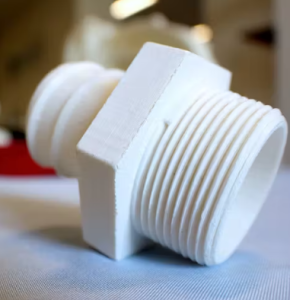

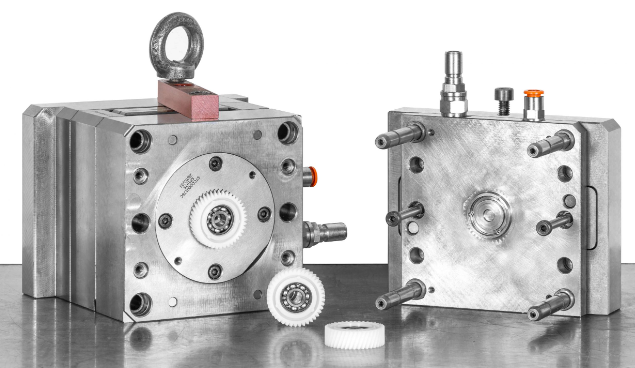

Rubber injection molding is a precise manufacturing process that involves injecting molten rubber into a mold to create custom rubber parts. This technique allows for the efficient production of complex shapes and designs while ensuring consistency and durability in the final product.

Benefits of Rubber Injection Molding

- Precision and Accuracy: Rubber injection molding provides high levels of precision, allowing for tight tolerances and consistent quality across all parts.

- Material Versatility: A variety of rubber materials can be used, including natural rubber, synthetic rubber, and liquid silicone rubber, catering to diverse application needs.

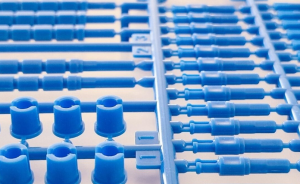

- Cost-Effective Production: Once the mold is created, the process is ideal for high-volume production, resulting in lower costs per part.

- Complex Geometries: This method enables the creation of intricate designs that may be difficult to achieve with other manufacturing processes.

Get Started with Our Rubber Injection Molding Services Today!

If you’re looking for reliable rubber molding services, DTG is here to assist you. Contact us today to discuss your project requirements and discover how our custom molded rubber solutions can meet your needs. Let us help you achieve excellence in your rubber component production.