Yes, acrylic, also known as polymethyl methacrylate (PMMA), can be injection molded. It’s a popular thermoplastic material with excellent optical clarity, good impact strength, and high surface finish. Injection molding is a common manufacturing process for acrylic due to its ability to produce complex shapes with high precision. Here’s an overview of the injection molding process for acrylic:

Characteristics of Acrylic (PMMA)

- Optical Clarity: Acrylic offers excellent optical properties, making it a popular choice for transparent or translucent applications.

- Impact Resistance: PMMA has good impact resistance compared to glass.

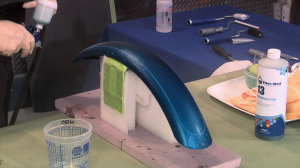

- Surface Finish: Acrylic can achieve a high-quality surface finish, which is important for applications requiring optical clarity.

- Chemical Resistance: It resists many chemicals, making it suitable for a wide range of applications.

Injection Molding Process for Acrylic

1. Material Preparation

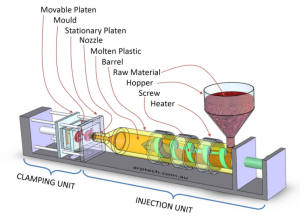

Drying: Acrylic is sensitive to moisture, so it needs to be properly dried before processing to prevent defects. The pellets are typically dried at temperatures between 70°C to 85°C (158°F to 185°F) for 2 to 4 hours.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

2. Machine Setup

Barrel Temperature: The barrel temperature for injection molding acrylic typically ranges from 180°C to 240°C (356°F to 464°F), depending on the grade of acrylic and the part requirements.

Mold Temperature: The mold temperature is critical for achieving high-quality, transparent parts. It typically ranges from 40°C to 80°C (104°F to 176°F), depending on the part design and thickness.

Injection Pressure: Acrylic requires moderate injection pressure, generally between 50 and 150 MPa (7250 to 21750 psi), depending on the part design and mold complexity.

3. Molding Process

Injection: Molten acrylic is injected into the mold cavity under high pressure. The injection speed and pressure must be controlled to ensure the mold is filled completely without voids or bubbles.

Cooling: Once injected, the acrylic needs to cool and solidify within the mold. The cooling time depends on the part thickness and complexity but typically ranges from 20 to 60 seconds.

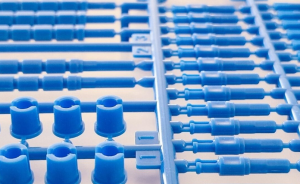

Ejection: After cooling, the mold opens, and the part is ejected. Care must be taken to ensure the part is not damaged during ejection.

Considerations for Molding Acrylic

- Shrinkage: Acrylic has a shrinkage rate of about 0.2% to 0.5%. Mold designs need to account for this to ensure accurate final dimensions.

- Optical Clarity: Maintaining the optical clarity of acrylic parts is crucial. Proper control of processing parameters, including temperature and pressure, is essential to minimize defects such as bubbles or haze.

- Mold Venting: Proper mold venting is important to prevent trapped air and reduce the risk of surface defects.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Applications of Injection Molded Acrylic

Due to its optical clarity and versatility, injection molded acrylic is used in various applications, including:

- Optical Components: Lenses, light guides, and optical windows.

- Consumer Products: Display cases, cosmetic packaging, and point-of-sale displays.

- Automotive: Headlamp lenses, taillight lenses, and interior trim components.

- Medical Devices: Laboratory equipment, cuvettes, and medical device housings.

- Electronic Enclosures: Covers, panels, and display screens.

Conclusion

Injection molding is a suitable process for producing high-quality acrylic parts with optical clarity and excellent surface finish. By carefully controlling the molding process parameters, manufacturers can produce durable and aesthetically pleasing parts suitable for a wide range of applications in various industries.

Related Conten: https://www.m-dtg.com/landing-page/high-quality-prototype-plastic-injection-molding/