What is acrylic molding?

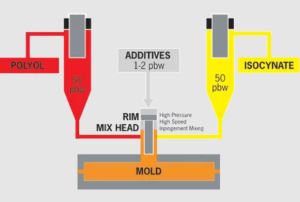

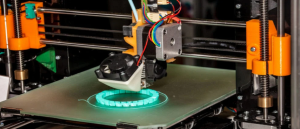

Acrylic molding is a process for producing plastic components from acrylic products. It involves melting acrylic pellets and infusing them right into a mold to form specific shapes. This technique is commonly made use of in different sectors because of acrylic’s flexibility and clarity.

5 Advantages of Polymer Injection Molding

1. Calls For Much Less Power

Polymer injection molding is energy-efficient. It requires less power compared to various other molding processes, making it an affordable alternative for suppliers. This effectiveness also adds to a lower ecological influence.

2. Environmentally Resistant

Polymer is highly resistant to ecological variables. It can withstand harsh weather conditions, consisting of UV exposure, without breaking down. This makes it ideal for outside applications and items that need to keep their look with time.

3. Immune to Chemicals

An additional advantage is that it generates parts that are immune to several chemicals. This chemical resistance is critical for applications in automobile, medical, and consumer goods industries, where direct exposure to numerous compounds is common.

4. Lightweight & Transparent

In the world of injection molding, acrylic is recognized for its light-weight homes and superb transparency. These features make it a prominent choice for products that call for a clear view, such as display cases, lenses, and safety barriers, while likewise being simple to take care of and set up.

5. Recyclable

Lastly, acrylic is a recyclable material which lines up with lasting production techniques. Parts made from this product can be recycled and repurposed, reducing waste and adding to a round economic climate.

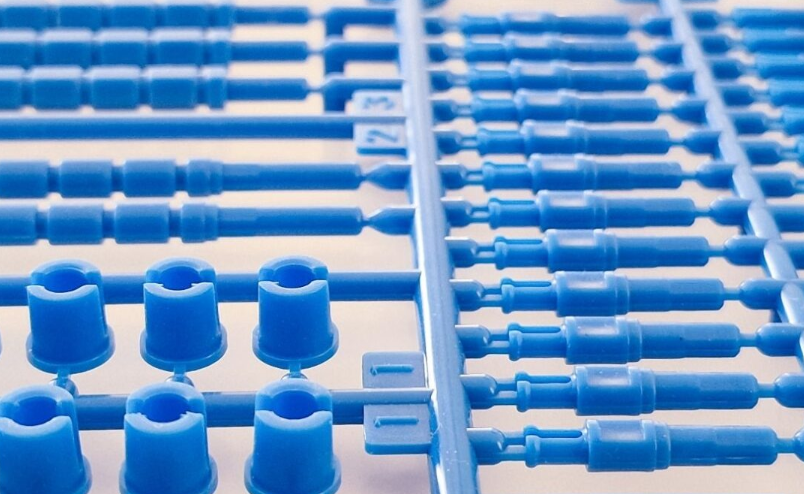

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Drawbacks

Despite its lots of benefits, acrylic does have some downsides. It can be more susceptible to damaging contrasted to various other plastics, and it might not be as solid as some alternatives like polycarbonate. Furthermore, the preliminary price of acrylic products can be higher, which might influence the overall cost-effectiveness for sure tasks.

What jobs are acrylic shot molding best for?

Acrylic molding is finest suited for tasks that call for clearness, lightweight residential properties, and ecological resistance. Illumination fixtures, vehicle parts, medical devices, and consumer electronic devices are all usual usages for acrylic. Acrylic’s adaptability and visual allure make it an excellent selection for a wide variety of applications. Whatever mold seems right for you, call us for a quote today!