Yes, acrylic, also known as polymethyl methacrylate (PMMA), can be injection molded. Acrylic is a popular material in various applications due to its clarity, strength, and ease of processing. Here’s an in-depth look at the process, challenges, and applications of injection molding acrylic:

Properties of Acrylic (PMMA)

- Clarity:

- Acrylic is highly transparent, allowing up to 92% of light to pass through, making it an excellent alternative to glass.

- Strength:

- Although not as strong as polycarbonate, acrylic is much stronger than glass and has good impact resistance.

- Weather Resistance:

- Acrylic is resistant to weathering and UV light, making it suitable for outdoor applications.

- Chemical Resistance:

- It resists many chemicals but can be attacked by certain solvents and alcohols.

- Ease of Processing:

- Acrylic is relatively easy to mold and can be fabricated into complex shapes.

Injection Molding Process for Acrylic

- Material Preparation:

- Acrylic should be dried thoroughly before molding to remove any moisture that could cause defects. Typical drying conditions are 80°C to 90°C (176°F to 194°F) for 2-4 hours.

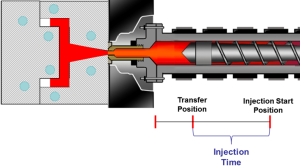

- Injection Molding Machine Setup:

- Temperature Control: Barrel temperatures typically range from 200°C to 250°C (392°F to 482°F), and the mold temperature should be between 40°C to 80°C (104°F to 176°F).

- Injection Pressure: Medium to high injection pressure is required to fill the mold cavity properly.

- Injection Speed: Moderate injection speed helps in avoiding defects like flow lines and air bubbles.

- Molding Cycle:

- Injection: The molten acrylic is injected into the mold cavity.

- Packing: Additional material is packed into the mold to compensate for shrinkage as the part cools.

- Cooling: The part is allowed to cool and solidify in the mold. Proper cooling time is essential to ensure dimensional accuracy and surface finish.

- Ejection: The solidified part is ejected from the mold.

- Post-Processing:

- Parts may require trimming to remove any flash. Polishing and surface treatments can enhance the clarity and appearance.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Challenges in Injection Molding Acrylic

- Moisture Sensitivity:

- Acrylic is hygroscopic and absorbs moisture from the air, which can cause defects during molding if not properly dried.

- Brittleness:

- Although strong, acrylic can be brittle and may crack or shatter under high impact or stress.

- Thermal Sensitivity:

- Acrylic has a relatively narrow processing window, and care must be taken to avoid thermal degradation.

- Surface Defects:

- Defects such as flow lines, air bubbles, and sink marks can occur if the processing parameters are not carefully controlled.

Applications of Injection Molded Acrylic

- Automotive:

- Tail lights, instrument clusters, and interior components.

- Lighting:

- Light covers, lenses, and diffusers.

- Consumer Goods:

- Display cases, picture frames, and household items.

- Medical Devices:

- Transparent components, covers, and housings.

- Signage and Displays:

- Indoor and outdoor signs, point-of-sale displays, and exhibition stands.

Benefits of Injection Molding Acrylic

- Optical Clarity: Ideal for applications requiring high transparency.

- Weather Resistance: Suitable for outdoor use and applications exposed to UV light.

- Versatility: Can be molded into complex shapes and designs.

- Surface Finish: Capable of achieving smooth, glossy surfaces without additional finishing.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Considerations

- Material Handling:

- Ensure acrylic is properly dried and handled to prevent moisture-related defects.

- Mold Design:

- Proper mold design, including smooth flow paths and adequate venting, is crucial to prevent defects and ensure quality.

- Processing Parameters:

- Precise control of temperature, pressure, and cooling time is essential for producing high-quality parts.

- Quality Control:

- Regular inspection and testing to ensure parts meet the required specifications and standards.

Conclusion

Acrylic is a versatile and widely used material that can be successfully injection molded into a variety of shapes and applications. By understanding and addressing the unique challenges associated with acrylic, manufacturers can produce high-quality, transparent, and durable parts for a wide range of industries. Proper drying, precise control of processing parameters, and careful mold design are essential for successful injection molding of acrylic.

Related Conten: Prototype Injection Molding