When it comes to manufacturing and material selection, two of the most commonly used plastics are ABS (Acrylonitrile Butadiene Styrene) and PS (Polystyrene). Both materials have their own strengths, weaknesses, and unique properties that make them ideal for different applications. Understanding the differences between ABS plastic and PS plastic can help in choosing the right material for your project. In this article, we’ll explore the characteristics of each plastic, compare them side by side, and examine their uses, advantages, and drawbacks.

What is ABS Plastic?

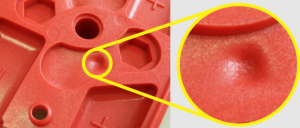

ABS plastic is a copolymer made from three monomers: Acrylonitrile, Butadiene, and Styrene. This blend of materials gives ABS its characteristic toughness, heat resistance, and impact resistance. ABS is widely used in applications requiring durability and impact resistance, such as automotive parts, toys, and appliances.

Key Properties of ABS:

- Toughness: Resistant to impact and shock.

- Heat Resistance: Can withstand higher temperatures without deforming.

- Stiffness: Provides rigidity and stability in solid forms.

- Surface Finish: Can be easily painted and finished, which makes it ideal for consumer products.

What is PS Plastic?

Polystyrene (PS) is a polymer made from the monomer styrene. It is one of the most common plastics, known for being rigid and easy to mold. PS plastic can be produced in two major forms: General Purpose Polystyrene (GPPS), which is clear and brittle, and High Impact Polystyrene (HIPS), which is modified to increase its toughness.

Key Properties of PS:

- Rigidity: PS is a hard, brittle plastic that does not offer much flexibility.

- Transparency: GPPS is often used in clear packaging or as a substitute for glass.

- Ease of Molding: PS is easy to mold into complex shapes.

- Cost-Effectiveness: Generally more affordable compared to other plastics like ABS.

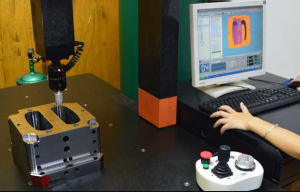

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

ABS Plastic vs. PS Plastic: Key Differences

| ABS Plastic | PS Plastic | |

| Strength and Durability | Known for its high impact resistance, ABS is tougher and more durable than PS. It’s a better option when strength and toughness are required, especially in automotive, electronics, and safety-related products. | PS is more brittle and prone to cracking under stress, making it less suitable for applications that require toughness. It’s ideal for packaging and lightweight uses, but not for structural parts. |

| Heat Resistance | It performs better in high temperatures, with a higher heat deflection temperature. | PS is less heat-resistant and can deform when exposed to moderate heat. |

| Flexibility | Offers a good balance of rigidity and slight flexibility, making it ideal for parts that need both strength and some resilience. | Generally rigid and brittle, lacking flexibility. |

| Surface Finish and Appearance | ABS plastic offers a smooth, high-quality finish and is easily painted. It’s ideal for visible consumer products such as home appliances, toys (like LEGO bricks), and automotive trim. | PS is often clear (in GPPS form) and can be made into transparent items like packaging, but the surface is not as smooth as ABS. |

Applications of ABS Plastic

ABS plastic is widely used in industries that require strong, durable materials:

- Automotive: Dashboard panels, bumpers, and trim.

- Consumer Electronics: Housings for electronic devices like printers, remote controls, and computers.

- Toys: Iconic products like LEGO bricks and action figures are made from ABS due to its strength and safety properties.

- Appliances: Used in the manufacture of kitchen appliances, vacuum cleaners, and hairdryers.

- 3D Printing: A common filament used in 3D printers due to its ease of use and durability.

Applications of PS Plastic

PS plastic, particularly in its general-purpose form, is used primarily in applications requiring rigidity but not necessarily strength:

- Packaging: Commonly used for food containers, disposable cutlery, and plastic cups.

- Toys and Models: Used for making low-cost models and figurines.

- Disposable Items: Cups, plates, and trays are often made from PS.

- Display Products: Due to its transparency, PS is used in point-of-purchase displays and packaging.

Advantages of ABS Plastic

- Impact Resistance: ABS is resistant to physical damage, making it ideal for high-stress environments.

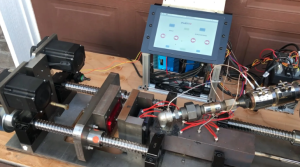

- Versatility: It can be easily processed via injection molding and is ideal for a wide range of products.

- High-Quality Finish: It has an excellent surface finish that is easy to paint and decorate.

- Temperature Resistance: ABS can withstand moderate to high temperatures without deforming.

Advantages of PS Plastic

- Cost-Effective: PS is one of the cheapest plastics to produce, making it ideal for low-cost products.

- Transparency: General-purpose polystyrene is clear, allowing for aesthetic or functional transparency.

- Ease of Processing: PS is easy to mold, making it perfect for complex shapes and detailed designs.

ABS Plastic vs. PS Plastic: Environmental Impact

Both ABS and PS plastics have environmental challenges:

- ABS: While ABS is durable and long-lasting, it is not biodegradable and can contribute to plastic waste. However, it is more likely to be recycled compared to PS.

- PS: PS is less environmentally friendly due to its brittleness, which makes it harder to recycle. It also contributes significantly to landfill waste, especially in disposable products like cups and packaging.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

How to Mold and Process ABS and PS Plastics

Both ABS and PS can be processed using injection molding and extrusion, though their processing temperatures vary:

- ABS: Requires a higher molding temperature (about 220-250°C) and is typically easier to process in thicker, more durable parts.

- PS: Requires a lower molding temperature (about 180-200°C) and is often used for thinner parts or parts that require transparency.

Cost Comparison: ABS vs. PS

- ABS: Generally more expensive than PS due to its tougher properties and more complex manufacturing process.

- PS: Much cheaper to produce and is often used in products where cost is a primary concern, such as disposable packaging.

Which Plastic Should You Choose?

The choice between ABS and PS depends on the requirements of the specific application:

- Choose ABS if you need durability, impact resistance, and temperature stability for long-lasting products.

- Choose PS if you need a cost-effective, rigid plastic for disposable products or clear packaging.

Conclusion

Both ABS plastic and PS plastic offer distinct advantages depending on the intended application. ABS is more durable, versatile, and heat-resistant, making it ideal for a wide range of consumer and industrial products. On the other hand, PS offers an affordable, easy-to-mold solution for low-cost, disposable, and clear products. Understanding the differences between these two plastics will help you make an informed decision based on your specific needs.