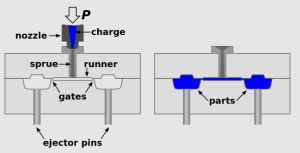

A family mold in injection molding refers to a single mold designed to produce multiple different parts simultaneously within one mold cycle. These parts are typically related and used together in the final assembly of a product. The use of family molds can be a cost-effective and efficient solution for manufacturing sets of parts that are intended to fit together or be assembled into a complete product.

Features of Family Molds

- Multiple Cavities for Different Parts:

- A family mold contains multiple cavities, each designed to produce a different part. These cavities are arranged in a single mold base, allowing the simultaneous production of various components.

- Single Mold Base:

- All the different cavities share the same mold base and are filled with molten plastic during a single injection cycle. This reduces the number of mold changes and improves production efficiency.

- Balanced Runner System:

- The mold design includes a runner system that ensures the molten plastic is evenly distributed to all cavities, providing uniform filling and minimizing variations between parts.

Advantages of Family Molds

- Cost Savings:

- Tooling Costs: Using a family mold can significantly reduce tooling costs because only one mold base is needed instead of multiple molds for each part.

- Production Costs: Producing multiple parts in a single cycle can lower production costs by reducing cycle times and increasing efficiency.

- Efficiency:

- Time Savings: Manufacturing multiple parts in one cycle reduces the total production time.

- Machine Utilization: Improved machine utilization as the injection molding machine produces several parts simultaneously.

- Consistency:

- Material Consistency: Since all parts are produced in the same cycle, they are subject to the same processing conditions, ensuring consistent material properties and quality across all parts.

Challenges of Family Molds

- Complex Design:

- Designing a family mold requires careful consideration to ensure that all cavities are properly balanced and that parts can be ejected without issues.

- Quality Control:

- Variations in part geometry and size can lead to differences in cooling rates and shrinkage, which need to be managed to maintain part quality.

- Injection Molding Process:

- Different parts might require slightly different processing conditions (e.g., pressure, temperature), which can be challenging to optimize in a single cycle.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Applications of Family Molds

Family molds are commonly used in industries where multiple parts are needed for a single product assembly. Examples include:

- Automotive Industry:

- Producing various interior components such as clips, fasteners, and decorative trims simultaneously.

- Consumer Electronics:

- Manufacturing different housing components, buttons, and connectors for devices like smartphones and remote controls.

- Household Appliances:

- Creating multiple plastic parts for appliances such as kitchen gadgets, vacuum cleaners, and other small electronics.

- Toys and Games:

- Producing different parts of a toy set, such as action figure components or building blocks.

Example:

Consider the production of a toy car. A family mold could be designed to simultaneously produce the car body, wheels, and other small parts in a single injection molding cycle. This approach ensures all components are made together, maintaining consistent quality and reducing overall production time and costs.

Conclusion

A family mold in injection molding is a valuable tool for producing multiple related parts in one mold cycle. By leveraging a single mold base with multiple cavities, manufacturers can achieve cost savings, improved efficiency, and consistent part quality. However, the design and optimization of family molds require careful consideration to balance the needs of different parts and ensure successful production.

Related Conten: Plastic Blow Molding