One significant trademark that is helpful to comprehend with regards to plastic model creation and additionally plastic part fabricating is the qualification among thermoplastic and thermoset materials. To spare the nitty-gritty details, thermoplastic materials can be liquefied, restored (chilled off to such an extent that they become strong), dissolved once more, relieved once more, etc. There is a cutoff to the times this interaction can be continued relying upon the specifics of the given material yet the fact is that thermoplastic materials can be liquefied on numerous occasions without fundamentally debasing the material. Thermoset materials, by differentiation must be dissolved once. After a thermoset material fixes, endeavoring to warm it again to its softening point would make it consume (instead of liquefy) the material. It is valuable to consider a 2-section epoxy while attempting to figure out thermoset plastics. An epoxy, similar to a thermoset material, is fluid before setting. When the sap dries, be that as it may, it is preposterous to expect to liquefy it once more.

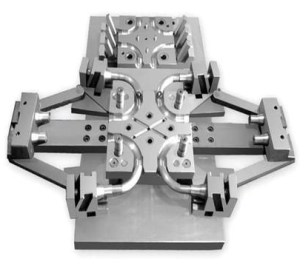

With regards to infusion forming misconception the importance of thermoset and thermoplastic materials is simple. First of all, both thermoset and thermoplastic polymers can be infusion formed. The essential contrast applies after the infusion form cycle (regularly a couple of moments in span) when the shaped plastic fixes (sets). During infusion forming plastic is warmed and afterward infused into a metal “device” (consider a 3D square with an inner hole looking like your last part). To truly get to the cavity the liquid plastic must initially go through a progression of passages and section focuses known as sprues, sprinters, and entryways. Plastic cools each cycle inside the shape cavity as well as inside these channels that lead to the pit. The material that sets in the sprues, sprinters, and entryways isn’t essential for the end result. It is basically squander.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

So what befalls this “squander” material during infusion forming?

- Thermoplastics:

If a thermoplastic material is being utilized for infusion shaping, it tends to be reused and utilized once more (periodically this happens right on the plant floor). Strong material left over after each cycle in the sprues, sprinters, and door areas can every now and again be joined with the natural substance that initially goes into the infusion shaping press. The equivalent is valid with material from dismissed parts or the flood material on the edges of parts where the form device was not 100 percent hermetically sealed. This plastic (called “regrind”) can be all ground up and reused once again into the start of the interaction. This all converts into higher effectiveness and eventually implies lower costs for the end buyer and a more serious or higher edge item for the maker. Of note, that doesn’t imply that an unequivocally planned shape device is superfluous for infusion shaping with thermoplastics. Running against the norm, customarily quality control estimates limit how much regrind that can be reused as a level of all out plastic to forestall likely debasement of material properties. - Thermosets:

If a thermoset material is being utilized, the strong material from the sprues, sprinters, and entryways is basically destined to be discarded as waste. That implies that any remaining things being equivalent (disclaimer: this is a terrible presumption) that the final result will cost more.

For what other reason does the differentiation among thermoplastics and thermoset materials matter?

As you would envision, similar qualities are pertinent toward the finish of a plastic part’s lifecycle when it comes time to either discard or reuse the material. Consider the plastic water bottles sold large number of times regular. The 500mL of water inside is polished off in no time while the container, whenever tossed into a landfill, would require many years to biodegrade. The quantity of plastic jugs in landfills in the long run turns into an ecological issue in the event that reusing isn’t a player simultaneously. Thusly most plastic jugs are made in entire or possibly to a limited extent from reused material. Investigate yourself. The pitch recognizable proof code on your plastic container is probably going to peruse “1” which distinguishes materials produced using polyethylene terephthalate (PET), a thermoplastic material.

All in all, thermoplastics give a few significant benefits to makers, customers, and society overall. The way that they can be handily reused implies that we are all the more mindfully managing our normal assets while the way that assembling waste can be reused (subsequently keeping it from becoming “squander” in any case) settles on them an ideal decision on the off chance that particular material properties aren’t solely accessible with a thermoset material.