Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, earning a strong following among engineers, machinists, and hobbyists alike. This technology allows for precise, efficient, and repeatable production of complex parts, making it a cornerstone in modern manufacturing. In this article, we will delve into the reasons why people like CNC machining, highlighting its numerous advantages and widespread appeal.

Precision and Accuracy

- High Precision

- Tight Tolerances: CNC machines can achieve incredibly tight tolerances, ensuring that parts are manufactured to exact specifications. This is critical in industries where precision is paramount, such as aerospace, medical, and automotive.

- Consistent Quality: The automated nature of CNC machining eliminates human error, providing consistent quality across multiple parts and production runs.

- Complex Geometries

- Intricate Designs: CNC machines can create complex shapes and intricate details that would be difficult or impossible to achieve with manual machining.

- Multi-Axis Machining: Advanced CNC machines can operate on multiple axes simultaneously, allowing for the creation of sophisticated and highly detailed components.

Efficiency and Productivity

- Automated Processes

- Reduced Manual Labor: CNC machining automates many of the manual tasks involved in traditional machining, freeing up operators to focus on other tasks.

- Increased Speed: Automated processes mean faster production times, enabling manufacturers to meet tight deadlines and increase output.

- High Repeatability

- Consistent Output: Once a CNC machine is programmed, it can produce identical parts repeatedly with minimal variation. This repeatability is essential for mass production and quality control.

- Quick Setup: CNC machines can be quickly reprogrammed for different tasks, reducing downtime between production runs and increasing overall efficiency.

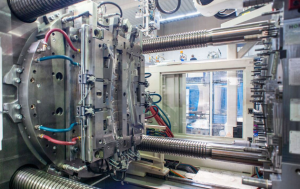

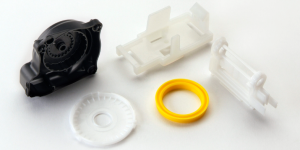

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Versatility and Flexibility

- Wide Range of Materials

- Material Compatibility: CNC machines can work with a variety of materials, including metals, plastics, wood, and composites, making them versatile tools for many applications.

- Custom Materials: The ability to machine custom materials allows for innovative product development and the use of advanced materials in manufacturing.

- Customization and Prototyping

- Rapid Prototyping: CNC machining is ideal for rapid prototyping, allowing designers to quickly produce and test prototypes before committing to full-scale production.

- Personalization: CNC machines enable the customization of products to meet specific customer needs, offering a level of personalization that is difficult to achieve with traditional manufacturing methods.

Cost-Effectiveness

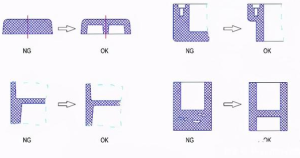

- Reduced Waste

- Material Efficiency: CNC machines are highly efficient in material usage, minimizing waste and reducing costs associated with excess material.

- Precision Cutting: The precise nature of CNC machining means less material is wasted during the cutting process, further reducing costs.

- Lower Labor Costs

- Automated Operations: The automation of CNC machines reduces the need for manual labor, lowering labor costs and increasing productivity.

- Long-Term Savings: Although the initial investment in CNC machinery can be high, the long-term savings in labor and material costs make it a cost-effective solution for many manufacturers.

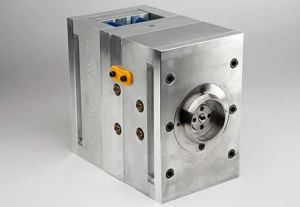

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Technological Advancements

- Integration with CAD/CAM

- Seamless Design to Production: CNC machines integrate seamlessly with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, streamlining the transition from design to production.

- Digital Twins: Advanced CNC systems can create digital twins of parts, allowing for precise simulations and optimizations before actual machining.

- Industry 4.0 and IoT

- Smart Manufacturing: CNC machines are increasingly connected to the Internet of Things (IoT), enabling real-time monitoring, data collection, and predictive maintenance.

- Enhanced Productivity: Industry 4.0 technologies enhance the capabilities of CNC machines, improving productivity, efficiency, and overall manufacturing intelligence.

Conclusion

People like CNC machining for its precision, efficiency, versatility, cost-effectiveness, and technological advancements. Whether in a large-scale industrial setting or a small workshop, CNC technology provides unparalleled benefits that enhance the manufacturing process. As CNC machining continues to evolve, its appeal will only grow, solidifying its place as an essential tool in modern manufacturing.

Related Conten: Injection Mold Manufacturing