Blog

Your resource center for the plastic injection molding industry, the "DTG" blog.

Home » Industry Knowledge

Industry Knowledge

How to Tell if Your Plastic Products Are Safe for Babies and Toddlers

Ensuring the safety of pl

Leo.Liu

1 2 月, 2025

没有评论

Industry Knowledge

The Importance of Thermoplastics To Product Development & Material Efficiency

One significant trademark

Leo.Liu

4 1 月, 2025

没有评论

Industry Knowledge

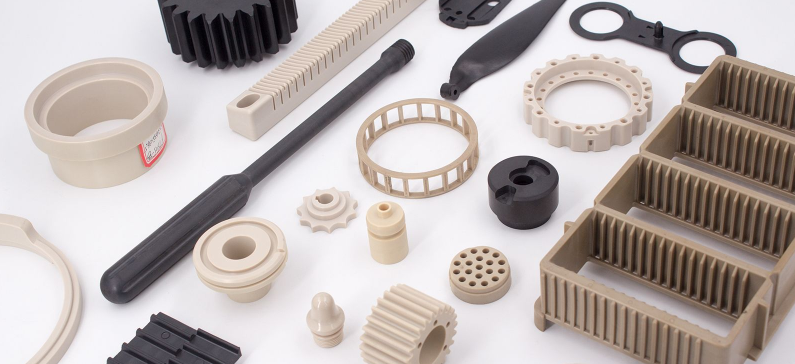

Peek Material and Plastic Injection Molding: A Comprehensive Guide

Introduction Polyethereth

Leo.Liu

24 12 月, 2024

没有评论