Introduction

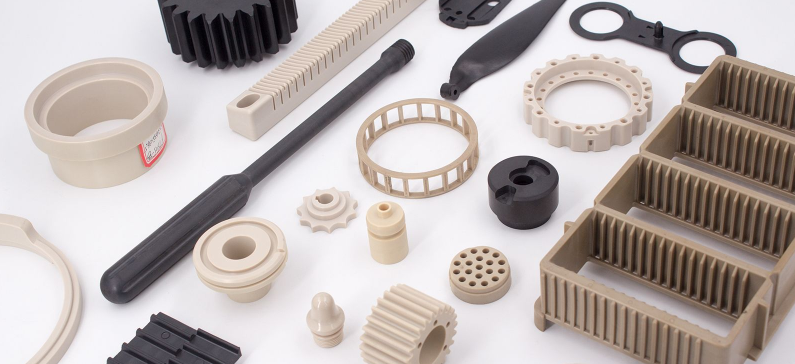

Polyetheretherketone (PEEK) is a high-performance thermoplastic that has revolutionized the world of engineering and manufacturing. Its exceptional properties—ranging from high thermal stability to excellent chemical resistance—have made it indispensable across multiple industries. On the other hand, plastic injection molding has become a cornerstone of modern manufacturing, allowing the efficient production of complex plastic components.

In this article, we’ll dive deep into the world of PEEK material and explore its synergy with plastic injection molding. By the end, you’ll understand why PEEK is a game-changer for manufacturing and how injection molding brings out its full potential.

Understanding PEEK

Key Properties of PEEK

PEEK is prized for its superior mechanical and chemical properties. These include:

- High Thermal Resistance: PEEK maintains stability at temperatures exceeding 250°C (482°F).

- Exceptional Strength and Durability: It withstands heavy mechanical stress without deforming.

- Chemical Resistance: PEEK is resistant to acids, bases, and solvents.

- Biocompatibility: It’s safe for medical implants and devices.

Chemical Composition and Structure

PEEK belongs to the polyaryletherketone (PAEK) family, characterized by repeating units of ketones and ethers. This molecular structure lends PEEK its remarkable stability and resistance to degradation.

Comparison with Other Plastics

Compared to other engineering plastics like polycarbonate (PC) and acrylonitrile butadiene styrene (ABS), PEEK offers unmatched performance in extreme conditions, though at a higher cost.

Applications of PEEK Material

Aerospace and Automotive

PEEK is extensively used in aerospace for components like bushings, bearings, and cable insulation due to its lightweight and heat-resistant nature. In automotive, it replaces metal parts in engines, reducing weight and improving fuel efficiency.

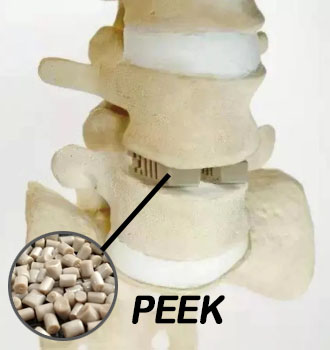

Medical and Healthcare

PEEK’s biocompatibility makes it ideal for spinal implants, dental components, and surgical instruments.

Industrial Applications

Industries like oil and gas rely on PEEK for parts like seals and valves that endure high pressure and corrosive environments.

Benefits of PEEK in Injection Molding

Durability and Strength

PEEK components are long-lasting and can endure extreme environments, reducing the need for frequent replacements.

High Heat Resistance

Injection-molded PEEK parts maintain dimensional stability even in high-temperature applications.

Biocompatibility

PEEK is safe for human contact, making it a top choice for medical devices.

Plastic Injection Molding Overview

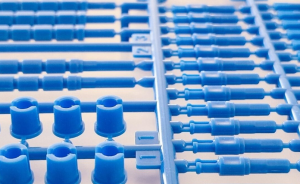

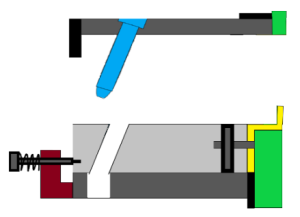

Process Explained Step-by-Step

- Material Preparation: PEEK pellets are pre-heated to remove moisture.

- Injection: The molten PEEK is injected into a mold cavity.

- Cooling: The part solidifies as it cools.

- Ejection: The finished part is removed from the mold.

- Finishing: Any additional trimming or polishing is done.

Types of Injection Molding Machines

- Hydraulic Machines: Cost-effective but less precise.

- Electric Machines: High precision with better energy efficiency.

- Hybrid Machines: Combines the benefits of hydraulic and electric systems.

Common Materials Used

Beyond PEEK, materials like polycarbonate, polypropylene, and nylon are frequently used.

Why Use PEEK in Injection Molding?

PEEK offers unique advantages that make it ideal for injection molding:

- Superior Performance: It delivers better strength and heat resistance than most other plastics.

- Design Flexibility: PEEK can be molded into intricate shapes with high precision.

- Longevity: Its resistance to wear ensures a longer lifespan for molded parts.

Process of Injection Molding PEEK

Pre-Heating and Melting Considerations

PEEK requires high processing temperatures of around 370–400°C (698–752°F). Proper pre-heating prevents defects like bubbles or uneven textures.

Mold Design Challenges

PEEK’s high melting point necessitates molds made of hardened steel to withstand wear.

Cooling and Finishing

Efficient cooling systems ensure uniform solidification. Post-molding, parts may need trimming or polishing.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Challenges with PEEK Injection Molding

- High Processing Temperatures: Specialized equipment is needed to handle PEEK’s high melting point.

- Material Cost: PEEK is more expensive than other thermoplastics, increasing upfront costs.

- Complex Mold Design: PEEK’s unique properties require precision mold design.

How to Overcome Challenges

- Proper Mold Design Tips: Use high-quality steel molds with polished cavities.

- Advanced Equipment Solutions: Invest in injection molding machines designed for high-performance materials.

- Skilled Workforce Requirements: Train operators to handle PEEK-specific challenges.

Case Studies

Successful Applications in Aerospace

A major aerospace company reduced aircraft weight by replacing metal components with PEEK.

Lessons from Medical Manufacturing

A healthcare company successfully used PEEK for spinal implants, improving patient outcomes.

Environmental Considerations

Recycling PEEK

Although challenging, PEEK can be recycled into lower-grade applications, reducing waste.

Sustainability in Manufacturing

Using PEEK in injection molding aligns with sustainability goals by producing durable, long-lasting parts.

Cost Analysis

Initial Setup Costs

The cost of PEEK material and specialized equipment can be high.

Long-Term Cost Benefits

However, the durability and reliability of PEEK parts often offset these initial expenses.

Future of PEEK and Injection Molding

Innovations in PEEK Technology

Researchers are developing composite forms of PEEK for enhanced performance.

Future Trends in Injection Molding

Automation and AI are set to revolutionize injection molding processes, improving efficiency and precision.

Tips for Choosing a Manufacturer

- Ask About Experience: Ensure the manufacturer has experience with PEEK injection molding.

- Check Certifications: Look for ISO certifications for quality assurance.

- Inquire About Equipment: Confirm they use advanced machinery suited for PEEK.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

FAQs

- What is PEEK used for?

PEEK is used in industries like aerospace, medical, and automotive for its durability and heat resistance. - Why is PEEK expensive?

Its superior properties and high processing temperatures contribute to its cost. - Can PEEK be injection molded?

Yes, PEEK is ideal for injection molding when handled with the right equipment and expertise. - Is PEEK eco-friendly?

PEEK is not biodegradable but can be recycled into secondary applications. - What makes PEEK better than other plastics?

PEEK offers unmatched thermal stability, strength, and chemical resistance. - How do I find a PEEK injection molding manufacturer?

Look for a company with relevant experience, certifications, and advanced equipment.

Conclusion

PEEK material, when combined with plastic injection molding, opens new frontiers in engineering and manufacturing. Its high performance, coupled with the versatility of injection molding, makes it an invaluable resource for industries seeking durability and precision.