Home » Case Products » Prototype Sheet Metal Parts: Precision Engineering for Custom Metal Components

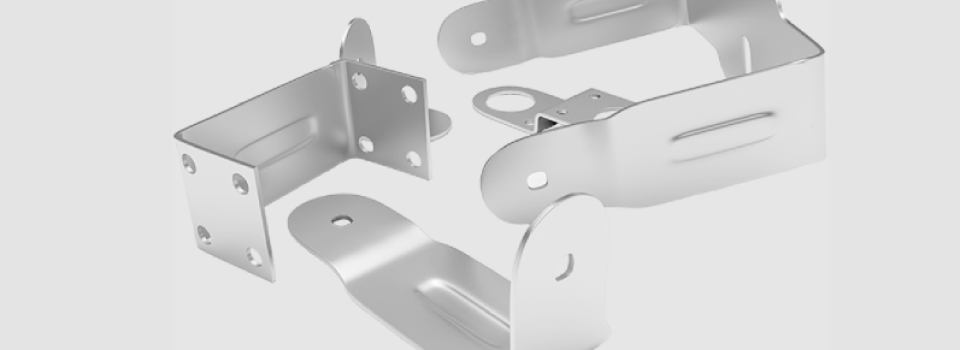

Prototype Sheet Metal Parts: Precision Engineering for Custom Metal Components

Bring your designs to life with our prototype sheet metal parts services, offering high-quality, precision-engineered metal components tailored to your specific needs. Whether you’re in the automotive, aerospace, or industrial equipment industry, our sheet metal prototyping services allow you to test and refine your designs before full-scale production, ensuring the highest standards of quality and functionality.

Why choose our prototype sheet metal parts services?

- High Precision: Achieve accurate and detailed prototypes with advanced sheet metal fabrication techniques, ensuring your parts meet exact specifications.

- Custom Solutions: Tailored prototyping services to match your unique design and material requirements, from simple brackets to complex enclosures.

- Rapid Turnaround: Speed up your product development with fast and efficient prototyping, reducing time-to-market and enabling quicker iterations.

- Versatile Applications: Ideal for a wide range of industries, including automotive, aerospace, electronics, and industrial equipment, providing the flexibility to create parts for various applications.

- Cost-Effective Development: Minimize production costs by validating and refining your designs early in the process, reducing the need for costly revisions later on.

Optimize your product development with our expert prototype sheet metal parts services. Contact us today to learn how we can help you create high-quality, functional prototypes that drive your project toward successful production.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

OEM Custom Sensor Housing – PA66 Plastic Injection Molding

Read more -

PVC Injection Molding

Read more -

Prototype Printing: Precision and Speed for High-Quality Prototypes

Read more -

Plastic Shell Electronic Plastic Accessories Factory Custom ABS Plastic Mold Processing

Read more -

Get Your Injection Molding Quote Today – Fast, Accurate, and Competitive

Read more -

Precision Injection Molding Tolerances at DTG Injection Molding

Read more