Maximize the durability and performance of your products with our PEEK injection molding services, providing high-precision molding of Polyether Ether Ketone (PEEK) components for industries such as aerospace, medical, automotive, and electronics. Known for its exceptional strength, heat resistance, and chemical stability, PEEK is ideal for demanding applications where standard plastics fall short.

Why choose our PEEK injection molding services?

- High-Performance Material: PEEK offers superior thermal stability, chemical resistance, and mechanical strength, making it perfect for high-stress environments such as medical implants, aerospace components, and automotive parts.

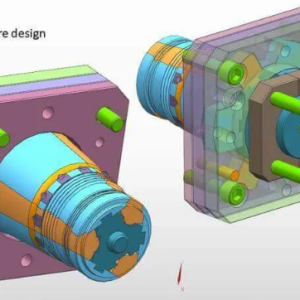

- Precision Molding: Our advanced injection molding processes ensure that PEEK components are manufactured with tight tolerances and exceptional detail, guaranteeing consistent, high-quality results.

- Custom Solutions: We work closely with you to create tailored PEEK injection molding solutions that meet your specific design, material, and performance needs.

- Cost-Effective Production: By using PEEK in injection molding, you achieve long-lasting, high-performance parts that reduce maintenance and replacement costs in critical applications.

- Fast Turnaround: Our streamlined manufacturing process ensures quick delivery of PEEK components, helping you speed up your product development cycle and get to market faster.

Experience the benefits of high-performance polymer components with our PEEK injection molding services. Contact us today to learn how we can deliver durable, precise, and reliable PEEK parts for your most demanding applications.