Injection molding is one of the most widely used manufacturing processes for producing high-precision parts in large volumes. However, there are situations where producing a large number of parts is not practical or cost-effective. This is where short run injection molding comes in.

Short run injection molding refers to the production of relatively small quantities of plastic parts, typically ranging from a few hundred to several thousand units. It’s often used for prototyping, limited production runs, and other applications where large-scale manufacturing is unnecessary or impractical.

What Is Short Run Injection Molding?

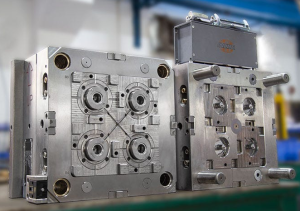

Short run injection molding involves using an injection molding machine to produce a limited quantity of parts. Unlike traditional injection molding, which is designed for high-volume production, short run molding is ideal for situations where fewer units are required or when a quick turnaround is needed. The process follows the same principles of injection molding, where plastic material is injected into a mold under high pressure, forming the desired shape.

The key difference lies in the scale:

- Traditional molding is aimed at mass production (often tens of thousands or more).

- Short run molding is designed to produce fewer units, making it more affordable for smaller quantities.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Benefits of Short Run Injection Molding

- Lower Initial Investment Costs

- In traditional injection molding, the cost of creating a mold can be prohibitively high. Short run molding uses simpler molds or even prototype molds, which significantly reduce initial costs. This makes it more accessible for smaller businesses or startups.

- Faster Turnaround Time

- Since short run injection molding involves fewer parts, the production time is often much faster than traditional manufacturing. This can be particularly beneficial for industries where speed is critical, such as medical devices or custom consumer products.

- Flexibility in Design Changes

- With short run molding, it’s easier and less expensive to modify the design or tooling for small batches. This flexibility is ideal for companies that may want to test different designs or iterate quickly based on feedback before committing to large-scale production.

- Lower Risk

- When producing a small number of units, the financial risk is much lower. If the design or material doesn’t meet expectations, it’s easier to adjust the process or design without incurring significant losses. It’s a safer approach for new product development or when entering new markets.

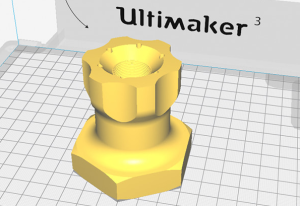

- Ideal for Prototyping and Testing

- Short run injection molding is commonly used for prototyping, as it provides a quick and cost-effective way to produce functional parts. This allows companies to test designs, materials, and manufacturing processes before committing to a full production run.

- Reduced Inventory and Storage Costs

- Since short run molding produces fewer parts, companies only need to manufacture the exact quantity they need. This reduces the need for large inventories and can significantly lower storage costs.

- Material Variety

- Short run molding allows for the use of a wide range of materials, including thermoplastics, elastomers, and composites. This gives designers and engineers the flexibility to choose the best material for their part’s requirements without being locked into large volumes of material.

- Better Quality Control

- Since fewer parts are being produced, manufacturers can focus more on the quality of each part. It’s easier to identify and address any issues early in the process, leading to higher-quality final products.

Use Cases for Short Run Injection Molding

- Prototyping and Product Development

- Short run injection molding is ideal for producing functional prototypes. These prototypes can be used for testing, validation, and obtaining customer or stakeholder feedback before mass production. This is particularly useful in industries like automotive, aerospace, and consumer electronics.

- Custom and Low-Volume Production

- Some products require custom, low-volume production due to their niche market. For example, custom parts for limited edition vehicles, machinery, or medical devices may be produced using short run injection molding.

- Market Testing and Consumer Products

- Before launching a product on a large scale, manufacturers often want to gauge market interest with a small production run. Short run molding allows them to quickly produce a limited batch of products for testing, reducing the risk of overproduction and excess inventory.

- Replacement Parts

- In industries like automotive or industrial machinery, there is often a demand for replacement parts that are no longer mass-produced. Short run injection molding can be used to create small batches of obsolete or custom replacement parts.

- Medical Device Manufacturing

- Medical devices often require small, precise runs of parts for regulatory testing, pilot studies, or initial market entry. Short run molding provides a fast and cost-effective solution for producing small quantities of specialized medical components that meet strict quality standards.

- Consumer Electronics

- Short run injection molding is commonly used for producing custom enclosures, housing parts, and other components for consumer electronics. It allows manufacturers to quickly iterate on designs and bring new products to market faster.

- Specialty Packaging

- Custom packaging for unique products—such as cosmetics, luxury items, or limited-edition goods—can benefit from short run molding. This allows brands to create unique packaging designs for specific market segments without the need for large-scale production.

- Educational or Promotional Items

- Companies often use short run injection molding to create promotional or educational items in small batches. This is perfect for custom giveaways, product samples, or unique corporate gifts.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

When to Choose Short Run Injection Molding

While short run injection molding offers many advantages, it is not always the best choice for every situation. Here are a few scenarios where short run molding is ideal:

- Low-Volume Production Needs: If you need a small number of parts (e.g., hundreds to a few thousand), short run molding provides a cost-effective solution without the high setup costs of traditional molding.

- Prototyping and Iterative Design: If you are in the early stages of product development or require frequent design changes, short run molding allows you to test different designs before committing to large-scale manufacturing.

- Custom Parts for Niche Markets: For industries where customized or specialized parts are needed in small quantities (e.g., medical, automotive, or aerospace), short run molding is an efficient and affordable option.

Conclusion

Short run injection molding offers a practical solution for manufacturers looking to produce small quantities of high-quality, custom parts quickly and affordably. Whether it’s for prototyping, limited edition products, or custom components, this process provides a way to reduce costs, lower risks, and speed up time-to-market. Its versatility across various industries makes it an invaluable tool for businesses looking to innovate without the high investment required for large-scale production runs.