Home » Case Products » Short Run Injection Molding

Short Run Injection Molding

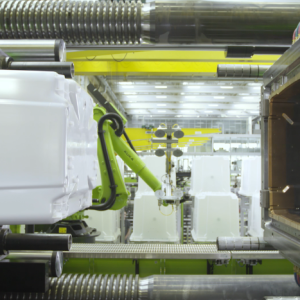

Our Short Run Injection Molding services, where we specialize in providing high-quality, cost-effective solutions for low volume production. Short run injection molding is ideal for projects that require a limited quantity of parts, offering flexibility, rapid turnaround, and reduced tooling costs. Our expertise ensures the production of precise and durable components tailored to your specific needs.

Key Features:

- Flexibility: Short run injection molding allows for the production of small quantities, ranging from a few dozen to a few thousand parts, providing flexibility for prototyping, market testing, and limited-edition products.

- Rapid Turnaround: Our efficient processes and advanced machinery enable quick setup and fast production cycles, ensuring rapid delivery of your parts.

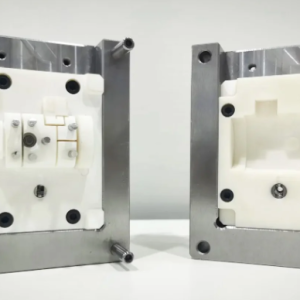

- Reduced Tooling Costs: We use cost-effective tooling options, such as aluminum molds or modular mold inserts, to minimize initial investment and reduce overall production costs.

- Customization: We offer tailored solutions, including custom part design, material selection, and surface finishes, to meet your unique requirements.

Applications:

Our Short Run Injection Molding solutions cater to a wide range of industries and applications, including:

- Prototyping: Creating functional prototypes for product development and testing, allowing for design validation and iteration before full-scale production.

- Market Testing: Producing limited quantities of parts for market trials, enabling businesses to gather customer feedback and assess demand.

- Custom and Limited-Edition Products: Manufacturing specialized or limited-edition parts for niche markets, promotional items, or customized products.

- Bridge Production: Providing interim production solutions while long-term production tooling is being developed, ensuring continuous supply of parts.

Benefits:

- Cost-Effective Production: Short run injection molding minimizes initial investment and overall production costs, making it an economical choice for low volume projects.

- Fast Turnaround: Quick setup and efficient production processes ensure rapid delivery of parts, meeting tight deadlines and project timelines.

- Design Flexibility: Short run injection molding allows for design changes and iterations, providing flexibility in product development and customization.

- Quality Assurance: Our stringent quality control protocols ensure that every part meets the highest standards of precision and durability, even in low volume production.

Why Choose Us?

- Expertise: With extensive experience in short run injection molding, we possess the technical knowledge and practical skills to deliver high-quality components that meet your specific requirements.

- Advanced Technology: Our state-of-the-art injection molding machines and tooling are optimized for low volume production, ensuring precision, consistency, and efficiency in every run.

- Quality Assurance: We implement stringent quality control protocols throughout the manufacturing process, from material selection to final inspection, ensuring that every part meets the highest standards of quality.

- Customer-Centric Approach: We work closely with our clients to understand their unique requirements and provide tailored solutions that enhance the functionality, performance, and marketability of their products.

Partner with Us:

Partner with us for your Short Run Injection Molding needs, and let us help you create high-quality, cost-effective components that excel in your industry. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Large Part Injection Molding Solutions

Read more -

Elevate Your Products with Expert Appliance Injection Molding Services

Read more -

Top Injection Mold Manufacturers: Your Partner for Precision and Quality

Read more -

Medical Injection Molding Companies: Precision Solutions for Healthcare Innovations

Read more -

China Mould Maker Custom Automobile Plastic Parts

Read more -

Innovative 3D Printed Injection Mold Solutions

Read more