Home » Case Products » Innovative 3D Printed Injection Mold Solutions

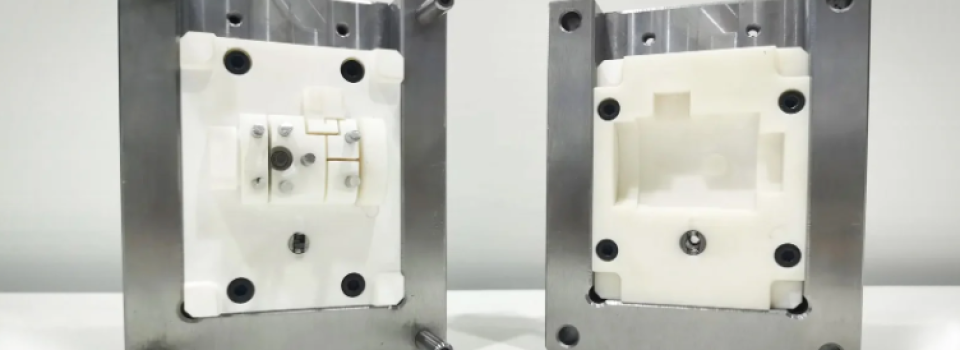

Innovative 3D Printed Injection Mold Solutions

At DTG Injection Molding, we are at the forefront of innovation, offering cutting-edge 3D printed injection mold solutions. By integrating advanced 3D printing technology with traditional injection molding, we provide our clients with faster, cost-effective, and highly customized mold solutions.

Why Choose 3D Printed Injection Molds?

- Rapid Prototyping: 3D printed injection molds significantly reduce lead times, allowing for rapid prototyping and quicker product development cycles.

- Cost-Effective: Lower tooling costs compared to traditional mold manufacturing, especially for small to medium production runs.

- Design Flexibility: Greater design flexibility and complexity can be achieved, enabling more intricate and detailed molds.

- Customization: Ideal for customized or low-volume production runs, providing tailored solutions that meet specific project requirements.

Our 3D Printed Injection Mold Capabilities

- Fast Turnaround: We leverage 3D printing to create injection molds quickly, reducing the overall production time.

- High Precision: Our advanced 3D printing technology ensures high precision and accuracy in mold creation.

- Material Versatility: We work with a variety of 3D printing materials to suit different injection molding applications.

- Prototyping and Production: Whether you need a prototype or a final production mold, our 3D printed injection molds are designed to deliver exceptional performance.

Applications of 3D Printed Injection Molds

Our 3D printed injection mold services are suitable for a wide range of industries and applications, including:

- Automotive: Custom parts and prototypes for automotive components.

- Consumer Electronics: Complex and detailed molds for electronic device housings.

- Medical Devices: Prototyping and small-scale production of medical components.

- Industrial Parts: Custom molds for specialized industrial equipment and machinery.

How to Get Started with Your 3D Printed Injection Mold Project

- Contact Us: Reach out to us via our online form, email, or phone to discuss your project requirements.

- Provide Specifications: Share your design files, material preferences, and expected quantity with our team.

- Receive a Quote: We will review your project details and provide a detailed, competitive quote within 24 hours.

- Project Execution: Upon approval, our team will begin the design and production process, ensuring timely and high-quality delivery.

Why Partner with DTG Injection Molding?

- Innovation and Expertise: Our team combines innovation with expertise to deliver top-notch 3D printed injection mold solutions.

- Quality Assurance: We adhere to strict quality control measures to ensure the highest standards of quality.

- Customer Focus: We prioritize customer satisfaction and work closely with our clients to ensure their needs are met and expectations exceeded.

Contact Us Today

Ready to revolutionize your injection molding process with 3D printed molds? Contact DTG Injection Molding today to discuss your requirements and receive a fast, accurate quote. Let us help you bring your vision to life with our innovative 3D printed injection mold services.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Customized Injection Molding ABS Plastic Product/Plug/Cover/Caps

Read more -

Enhance Your Products with Injection Molding Overmolding

Read more -

Plastic Cover, Cap Plastic Injection Molding

Read more -

Custom Metal Fabrication Prototype: Precision Prototyping for Advanced Product Development

Read more -

Soft Plastic Injection Molds Plastic Shrimp, Plastic Bug, Plastic Lures

Read more -

Discover Our Custom Plastic Cups – Plastic Injection Molding

Read more