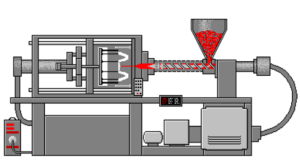

Clamping force in injection molding is the pressure applied by the injection molding machine to hold the two halves of the mold (the core and the cavity) together during the injection and cooling phases of the molding cycle. This force is critical to ensure that the mold remains closed and properly aligned while the molten plastic is injected into the mold cavity under high pressure.

Key Aspects of Clamping Force

- Function of Clamping Force

- Preventing Flash: Clamping force prevents flash, which is the leakage of molten plastic between the mold halves. Flash can occur if the mold is not clamped tightly enough, leading to material wastage and defects in the part.

- Maintaining Mold Integrity: Ensures that the mold remains closed and the two halves do not separate, maintaining the part’s dimensional accuracy and surface quality.

- Balancing Injection Pressure: Counteracts the high pressure exerted by the molten plastic as it is injected into the mold cavity. Proper clamping force ensures the mold stays closed despite this pressure.

- Calculating Clamping Force

- Part Area: The surface area of the part(s) being molded (projected area) is a key factor in determining the required clamping force.

- Injection Pressure: The pressure at which the molten plastic is injected into the mold also influences the necessary clamping force.

- Safety Factor: A safety factor is often included to account for variations in pressure and material flow.

- Formula: A common formula to estimate clamping force is: Clamping Force (tons)=Projected Area (in2)×Injection Pressure (psi)×Safety Factor Typically, a safety factor of 1.1 to 1.5 is used.

- Units of Measurement

- Clamping force is typically measured in tons (U.S. system) or metric tonnes (metric system).

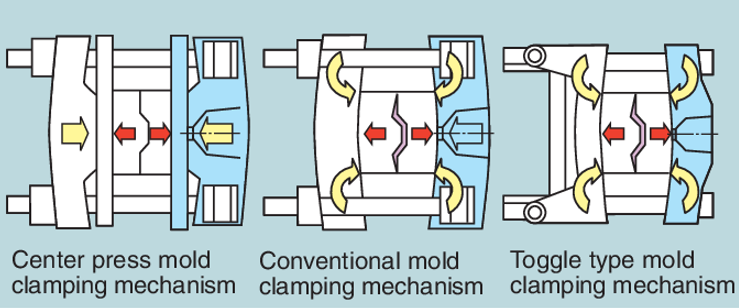

- Machine Specifications

- Injection molding machines are rated by their clamping force capacity, which can range from a few tons for small machines to several thousand tons for large machines.

Importance of Correct Clamping Force

- Part Quality

- Flash Prevention: Sufficient clamping force ensures that no molten plastic escapes the mold, preventing flash and ensuring clean edges on the molded parts.

- Dimensional Accuracy: Maintaining proper clamping force helps ensure that the mold closes evenly and the parts maintain their intended dimensions.

- Mold Protection

- Preventing Mold Damage: Excessive clamping force can damage the mold, leading to increased maintenance costs and potential downtime.

- Mold Life: Using the correct clamping force optimizes mold life by reducing wear and tear on the mold components.

- Process Efficiency

- Cycle Time: Correct clamping force contributes to consistent cycle times, which is crucial for maintaining production efficiency.

- Energy Consumption: Applying the optimal clamping force reduces the energy consumption of the machine, contributing to cost savings and environmental sustainability.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Adjusting Clamping Force

- Machine Settings: Most modern injection molding machines allow operators to set and adjust the clamping force through the machine’s control interface.

- Testing and Validation: Adjustments to clamping force should be validated through testing to ensure optimal part quality and process stability.

Summary

Clamping force is a critical parameter in the injection molding process, necessary for keeping the mold securely closed during injection and cooling. It prevents defects such as flash, ensures dimensional accuracy, and protects the mold from damage. Proper calculation and adjustment of clamping force are essential for achieving high-quality parts and efficient production.

Related Conten: https://www.m-dtg.com/service/prototype-injection-molding/