Home » Case Products » Painting Injection Molded Plastic

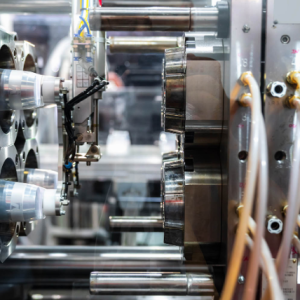

Painting Injection Molded Plastic

We offer high-quality painting solutions to enhance the appearance, durability, and functionality of your plastic parts. Whether you need custom colors, textures, or finishes, our painting process ensures a flawless surface that meets your exact specifications.

Our Process:

- Surface Preparation: We begin by thoroughly cleaning and preparing the surface of the injection molded plastic parts to remove any contaminants or residues that may affect adhesion.

- Priming: A specialized primer is applied to the surface of the plastic parts to promote adhesion and improve paint durability. The primer also helps to fill in any small imperfections in the surface, ensuring a smooth finish.

- Paint Application: We use high-quality paints that are specifically formulated for use on plastic surfaces. Our skilled painters apply the paint evenly and precisely to achieve the desired color, texture, and finish.

- Curing: After painting, the parts are cured in a controlled environment to ensure proper drying and bonding of the paint to the plastic surface. Curing may involve heat, UV light, or chemical processes, depending on the type of paint used.

- Quality Inspection: Each painted part undergoes rigorous quality inspection to ensure that the finish meets our strict standards for adhesion, color accuracy, and surface quality.

Key Features:

- Customization: Our painting process allows for complete customization of colors, textures, and finishes to match your branding or design requirements.

- Durability: We use high-quality paints and primers that are resistant to chipping, scratching, and fading, ensuring long-lasting durability even in demanding environments.

- Enhanced Appearance: Painting injection molded plastic parts can enhance their appearance and create a more professional and aesthetically pleasing finish.

- Protection: Paint provides an additional layer of protection to plastic parts, helping to shield them from environmental factors such as UV exposure, moisture, and chemicals.

Applications:

Our painting services for injection molded plastic components are suitable for a wide range of industries and applications, including:

- Automotive interiors and exteriors

- Consumer electronics

- Medical devices

- Industrial equipment

- Consumer goods

- Household appliances

Why Choose Us?

- Expertise: With years of experience in plastic painting, we have the knowledge and skills to deliver exceptional results that meet your specific requirements.

- Quality Assurance: We adhere to strict quality control standards throughout the painting process to ensure that every part meets the highest standards of quality and durability.

- Custom Solutions: We work closely with our clients to understand their needs and provide customized painting solutions that meet their unique specifications and budget.

Contact Us:

Partner with us for your painting needs for injection molded plastic components, and let us help you achieve the perfect finish for your parts. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Metal Injection Molding in China: Precision and Efficiency for Your Metal Parts

Read more -

Silicone Plastic Injection Molding

Read more -

Leading Injection Mold Companies: Your Partner in Precision Manufacturing

Read more -

Precision Injection Molding: Achieve Exceptional Accuracy with DTG Injection Molding

Read more -

Understanding the Rubber Injection Molding Process: A Comprehensive Guide

Read more -

Injection Molding Threaded Inserts

Read more