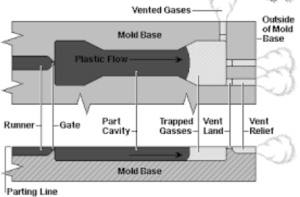

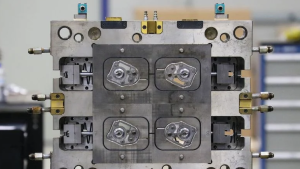

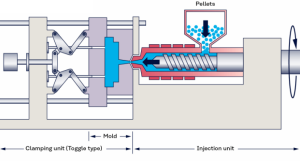

Injection molding is a manufacturing process that creates plastic components. It is a popular method for low-volume manufacturing, pilot-run, and prototyping of styles. Injection molding has 2 major sorts of mold styles: hot runner and chilly runner. A hot runner mold uses a heated jogger to transfer liquified polycarbonate or polymer to the mold and mildew dental caries where the final product takes on its shape. A cold jogger mold and mildew uses an unheated runner network to transfer the molten product from the device nozzle to the mold cavity.

While these 2 techniques both generate plastic components, warm jogger mold and cold jogger mold systems vary in regards to price, speed, and accuracy of the molded parts. Hot jogger mold and mildews are much more expensive to set up and preserve than their cool runner equivalents. However, hot runner mold and mildews create parts with a higher level of resistance and have a shorter lead time. A cool runner mold, on the other hand, is much more inexpensive and collaborates with a large variety of polycarbonate products including heat-sensitive types.

Warm Jogger Definition and Contrast to Cold Running Molds

A warm runner is a shot molding system that makes use of a manifold as the heating element. It was first produced and advertised by Mold-Masters Ltd in 1963. The runner, which is comprised of 2 plates, is warmed together with the molten polycarbonate. As the molten plastic moves with the runner, the manifold ensures harmony in the temperature level of the home heating cyndrical tube and the runner. The liquified plastic is fed to the nozzle, which in turn loads the mold and mildew cavity. Later, the molded plastic is expelled free of the jogger. Contrasted to the chilly runner mold and mildew, the warm jogger mold creates even more components each time. To read more, see our guide on What is a Warm Jogger.

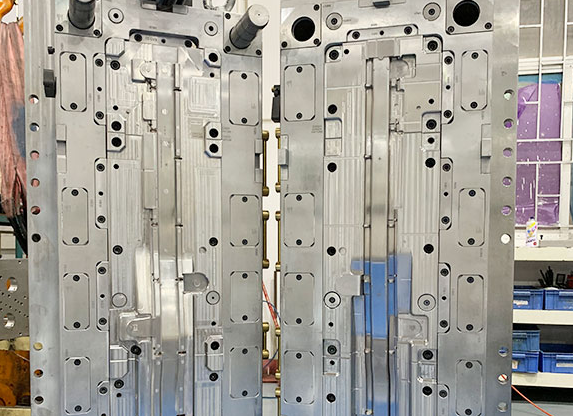

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

The Advantages and Negative Aspects of Hot Runner Compared to Cold Running Mold And Mildews

Some advantages of hot jogger vs. cold running molds are:

- Hot jogger molds do not require the help of robotics to separate the jogger from the mold, unlike the cool runner mold.

- The parts generated by warm jogger molds are much more exact in their measurements than those from cold runner mold and mildews.

- Larger quantities and dimensions of parts can be produced by warm runner molds.

Several of the disadvantages of hot runner vs. cold running are:

- Warm runner molds have greater upkeep costs contrasted to chilly running molds.

- Warm jogger molds do not match some heat-sensitive thermoplastic products compared to chilly running molds.

- It is difficult to make shade changes in hot jogger molds.

Cold Running Mold And Mildews Definition and Contrast to Hot Jogger

Cold running molds utilize unheated runners to convey liquified thermoplastic material from the nozzle to the mold or dental caries. These are made up of two or 3 plates, depending on the design. When the procedure is total, the runner comes out affixed to the molded part. A chilly running mold and mildew is often chosen over a warm jogger mold and mildew because of the low arrangement and maintenance price.

The Advantages and Drawbacks of Cold Running Mold And Mildews Contrasted to Hot Runners

Some benefits of chilly running mold and mildews contrasted to hot runner molds are:

- Cold running mold and mildews fit a variety of thermoplastics compared to hot jogger molds.

- Cold running molds are cost-effective compared to hot runner molds.

- Cold running mold and mildews permit quick modifications in style or shade.

The downsides of cold running molds contrasted to hot jogger molds are:

- Cold running molds produce even more waste than warm runner mold and mildews.

- Cold running mold and mildews produce get rid of lower resistances than those of warm runner mold and mildews.

- The production process of cold running mold and mildews is slower than hot jogger molds. Therefore a lower number of parts can be created by means of cool running molds.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Hot Jogger and Cold Jogger

The warm runner mold and mildew creates get rid of a tighter resistance than those of a chilly running mold and mildew. Nonetheless, when modifications in layout or shade are needed, a chilly running mold is the very best alternative.

Price Comparison

Warm runner mold and mildews have a greater configuration and upkeep expense. It is generally an extra pricey alternative to chilly jogger molds. Nevertheless, in some cases, the high price of waste manufacturing in cold runner molds counteracts any prospective price savings. The inappropriate monitoring of waste can raise the total expense of manufacturing.

Rate Contrast

A warm jogger mold generates even more components each of time than chilly jogger parts. This is since chilly runner mold and mildews require to separate the runner from the mold and grind and recycle the runner to prevent waste. On the other hand, hot jogger molds are not impacted by any one of these factors, so the lead time is much shorter.

Volume Contrast

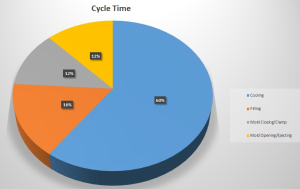

A bigger quantity of components can be generated with hot jogger mold and mildew than with cool runner molds, as the use of the warm runner removes the need to divide the jogger from the component. This minimizes the cycle time and allows for faster processing of products.

Products Contrast

When contrasting hot jogger vs. cold jogger when it come to the sorts of polycarbonate products used, it is helpful to recognize just how adversely hot jogger mold and mildews effect thermal-sensitive material or polymers. Materials that are especially conscious heat must not be made use of in this system. The elimination of the heating element in cool joggers makes them suitable with a lot of polymers or thermoplastics consisting of thermal-sensitive options.