Yes, vents are indeed used in injection molding. Vents play a crucial role in the injection molding process by allowing trapped air and gases to escape from the mold cavity as the molten plastic is injected. Here’s a detailed explanation of their importance and how they function:

Importance of Vents in Injection Molding

1. Preventing Defects

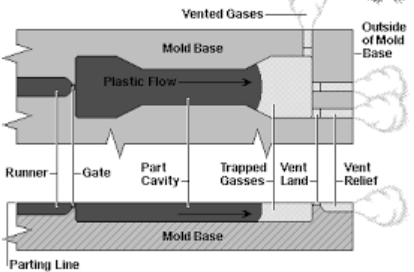

- Air Trapping: During the injection molding process, air trapped in the mold cavity can lead to defects such as burn marks, incomplete filling, or air bubbles in the finished part.

- Gas Release: Vents allow not only air but also gases generated by the heating of the plastic to escape, which is essential for maintaining the quality of the molded part.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

2. Ensuring Complete Filling

- Smooth Flow: Vents help ensure that the molten plastic fills the entire mold cavity smoothly and evenly, which is particularly important for complex or intricate designs.

- Pressure Management: By allowing trapped air to escape, vents help maintain the necessary pressure within the mold cavity to ensure complete and accurate filling.

3. Improving Part Quality

- Surface Finish: Proper venting reduces the likelihood of surface imperfections and enhances the overall appearance of the molded part.

- Structural Integrity: Venting helps prevent internal stresses and weaknesses, resulting in stronger, more durable parts.

How Vents Function in Injection Molding

1. Location and Design

- Strategic Placement: Vents are strategically placed at the end of the flow path or in areas where air is likely to be trapped. This placement ensures efficient venting without compromising the part’s structural integrity.

- Size and Shape: Vents are typically very narrow (often just a few thousandths of an inch wide) and can be designed as shallow channels, pins, or porous inserts.

2. Types of Vents

- Edge Vents: Located along the parting line of the mold, these are the most common type of vents.

- Pin Vents: Used in deeper areas of the mold where air may be trapped, pin vents are small, cylindrical passages that allow air to escape.

- Porous Vents: Made from materials like sintered metal, porous vents allow air to escape through tiny interconnected pores while preventing the escape of molten plastic.

3. Maintenance and Optimization

- Regular Cleaning: Vents must be regularly cleaned to prevent blockages that can impede their function.

- Optimization: The design and placement of vents can be optimized using simulation software to predict airflow and potential trapping points within the mold cavity.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Sources and Further Reading

For more detailed information on the role of vents in injection molding, you can refer to resources such as:

- Plastics Technology

- Injection Molding Resources

- Scientific Molding

These sources provide in-depth explanations and practical guidelines on the design, implementation, and maintenance of vents in the injection molding process.

Related Conten: Quick Turn Injection Molding