Home » Case Products » Premium Quality Injection Molding Mold Parts for Precision Manufacturing

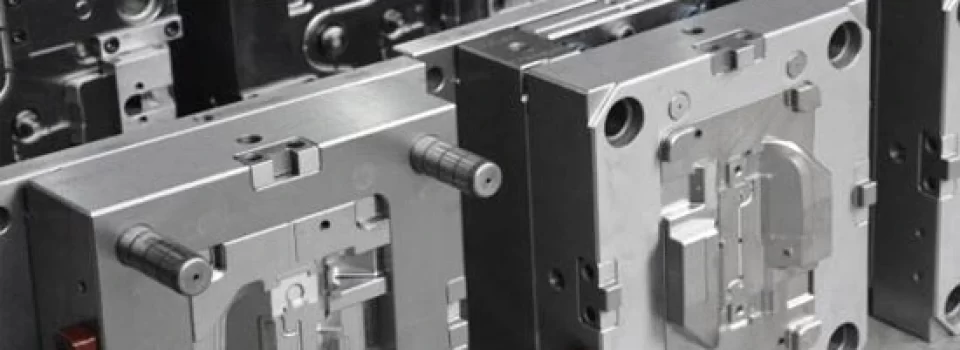

Premium Quality Injection Molding Mold Parts for Precision Manufacturing

For industries that rely on precise and efficient production, high-quality injection molding mold parts are crucial. At DTG injection molding, we specialize in providing top-tier mold components that ensure the success of your injection molding processes. Discover the benefits of partnering with us for all your mold part needs.

Why Choose Our Injection Molding Mold Parts?

- Superior Materials: Our mold parts are manufactured using high-grade materials, including hardened tool steel, stainless steel, and high-performance alloys. This ensures durability, strength, and longevity in even the most demanding applications.

- Precision Engineering: We utilize advanced manufacturing technologies and rigorous quality control processes to produce mold parts with exceptional accuracy. Our precision-engineered components guarantee optimal performance and minimal downtime.

- Customization: We offer custom mold part solutions tailored to your specific requirements. Whether you need standard components or specialized parts, our team can design and manufacture mold parts that meet your exact specifications.

- Comprehensive Range: Our product lineup includes a wide variety of injection molding mold parts, such as ejector pins, mold bases, core pins, cavity inserts, and guide components. We provide everything you need to maintain and optimize your injection molds.

- Expert Support: Our experienced engineers and technicians are available to provide technical support and guidance. We work closely with our clients to ensure they receive the best solutions for their injection molding operations.

Our Injection Molding Mold Parts

- Ejector Pins: High-quality ejector pins designed for reliable performance and extended service life.

- Mold Bases: Durable and precisely machined mold bases to support a variety of molding applications.

- Core Pins: Customizable core pins with exceptional hardness and wear resistance.

- Cavity Inserts: Precisely engineered cavity inserts for accurate molding and easy replacement.

- Guide Components: Comprehensive selection of guide pins, bushings, and other guide components for smooth mold operation.

Industries We Serve

- Automotive: Mold parts for producing high-precision components such as engine parts, interior trim, and safety features.

- Medical: Components for medical devices, surgical instruments, and diagnostic equipment requiring stringent quality standards.

- Consumer Goods: Durable and high-quality mold parts for a variety of consumer products, including electronics and household items.

- Aerospace: Lightweight and robust mold parts for aerospace applications that demand high performance and reliability.

Contact Us for High-Quality Injection Molding Mold Parts

Ready to enhance your injection molding processes with premium mold parts? Contact us today to discuss your needs and receive a personalized quote. Our team is dedicated to delivering top-notch products and exceptional service.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Glass Injection Molding

Read more -

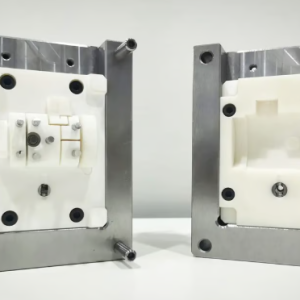

Revolutionize Your Manufacturing with 3D Printed Injection Molds

Read more -

PTFE Injection Molding Solutions

Read more -

Thin Wall Injection Molding

Read more -

Auto Steering Wheel Trim Plate – Custom Injection Molding

Read more -

Plastic Cover, Cap Plastic Injection Molding

Read more