Home » Case Products » Elevate Your Products with Thermoplastic Polyurethane Injection Molding

Elevate Your Products with Thermoplastic Polyurethane Injection Molding

Thermoplastic Polyurethane (TPU) injection molding is a versatile and highly effective process for producing durable, flexible, and high-performance parts. At DTG Injection Molding, we leverage advanced TPU injection molding techniques to deliver superior components that meet the diverse needs of various industries.

What is Thermoplastic Polyurethane (TPU)?

Thermoplastic Polyurethane (TPU) is a unique material known for its elasticity, transparency, and resistance to oil, grease, and abrasion. These properties make TPU an ideal choice for creating parts that require flexibility, durability, and high performance.

Benefits of TPU Injection Molding

- Superior Flexibility and Elasticity

- Overview: TPU offers exceptional flexibility and elasticity.

- Benefits: Ideal for applications requiring parts that can bend, stretch, and flex without losing their shape.

- High Durability and Resistance

- Overview: TPU is resistant to oil, grease, chemicals, and abrasion.

- Benefits: Ensures long-lasting performance in harsh environments and demanding applications.

- Transparency and Aesthetic Appeal

- Overview: TPU can be produced with a high degree of transparency.

- Benefits: Perfect for products that require a clear, attractive appearance.

- Versatile Applications

- Overview: TPU can be used in a wide range of industries and applications.

- Benefits: Provides a versatile solution for automotive, medical, consumer electronics, and more.

Applications of TPU Injection Molding

Automotive Components

TPU injection molding is widely used in the automotive industry to produce parts that require flexibility and durability, such as seals, gaskets, and protective covers. These components benefit from TPU’s resistance to oil, grease, and abrasion, ensuring long-lasting performance in demanding automotive environments.

Medical Devices

In the medical field, TPU is utilized to manufacture components that require flexibility, biocompatibility, and transparency. Examples include tubing, catheters, and medical device housings. TPU’s properties make it an excellent choice for medical applications that demand high performance and reliability.

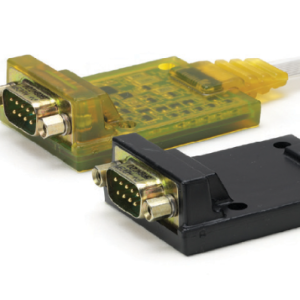

Consumer Electronics

TPU injection molding is ideal for creating protective cases, flexible connectors, and other components in consumer electronics. The material’s flexibility, durability, and aesthetic appeal make it a popular choice for products such as smartphone cases, wearable device bands, and flexible keyboards.

Why Choose DTG for TPU Injection Molding?

Advanced Technology and Expertise

At DTG Injection Molding, we utilize state-of-the-art TPU injection molding technology and our team’s extensive expertise to deliver exceptional results. Our commitment to innovation ensures that we stay at the forefront of industry advancements, providing you with the best solutions for your projects.

Customized Solutions

Every project is unique, and we provide customized TPU injection molding solutions tailored to your specific needs. Our team works closely with you to understand your requirements and deliver parts that meet your exact specifications, ensuring optimal performance and satisfaction.

Quality Assurance

We adhere to rigorous quality control measures throughout the production process. From material selection to final inspection, we ensure that each part meets the highest standards of quality and performance, giving you confidence in the reliability of your products.

Our TPU Injection Molding Process

- Initial Consultation

- Overview: Discuss your project requirements and objectives with our experts.

- Benefits: Gain a clear understanding of your needs for tailored solutions.

- Design and Engineering

- Overview: Develop detailed designs and engineering plans.

- Benefits: Ensure optimal part performance and functionality.

- Material Selection

- Overview: Choose the best TPU materials for your application.

- Benefits: Enhance the durability and performance of the final parts.

- Prototype Development

- Overview: Create and test prototypes to validate designs.

- Benefits: Refine and optimize parts before full-scale production.

- Production and Quality Control

- Overview: Use advanced TPU injection molding technology for precise and efficient production.

- Benefits: Produce high-quality parts that meet all specifications and standards.

Contact DTG Injection Molding Today

Ready to explore the benefits of TPU injection molding for your next project? Contact DTG Injection Molding to learn more about our services and how we can help you achieve superior results with our advanced TPU capabilities.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Drive Innovation with Injection Molding Automotive Parts

Read more -

Custom Frosted Plastic Cups

Read more -

Custom Plastic Injection Molding for Auto Courtesy Light Warning Lamps

Read more -

Low Pressure Injection Molding Solutions

Read more -

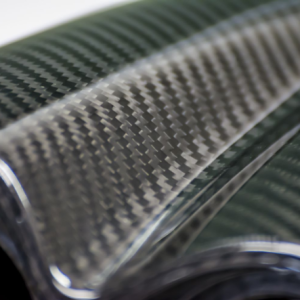

Carbon Fiber Injection Molding

Read more -

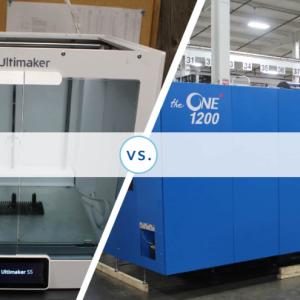

3D Printing vs Injection Molding: Which is Right for Your Project?

Read more