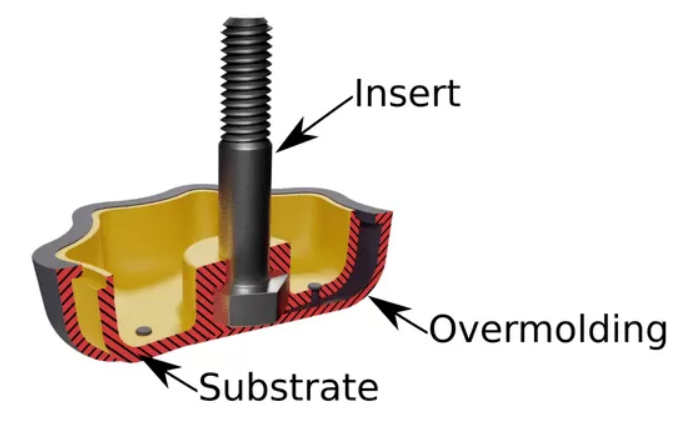

Overmolding is a specialized injection molding process used to create multi-material parts, combining two or more different materials into a single integrated component. This technique is widely used in various industries, including automotive, medical, electronics, and consumer products, to enhance functionality, improve aesthetics, and add value to the final product.

How Does Overmolding Work?

Overmolding involves two primary steps:

- Injection Molding of the Substrate: The process begins by creating the initial part, known as the substrate, using standard injection molding. The substrate is typically made of a rigid thermoplastic material.

- Overmolding the Substrate: The substrate is then placed into a second mold, where a different material is injected over it. This secondary material is often a softer thermoplastic or elastomer, which bonds to the substrate, forming a single cohesive unit.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Types of Overmolding

- Two-Shot Molding: Also known as multi-shot molding, this method involves two distinct injection molding cycles within the same machine. The first shot creates the substrate, and the second shot overmolds the additional material.

- Insert Molding: In this technique, the pre-formed substrate is manually or robotically placed into the mold, where it is overmolded with the secondary material.

Materials Used in Overmolding

- Substrate Materials: Typically, rigid thermoplastics such as polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polypropylene (PP).

- Overmold Materials: Generally, softer materials like thermoplastic elastomers (TPE), thermoplastic polyurethane (TPU), and silicone.

Benefits of Overmolding

- Enhanced Functionality: Overmolding allows for the combination of materials with different properties, creating parts with enhanced functionality. For example, a rigid plastic part overmolded with a soft elastomer can provide both structural integrity and ergonomic comfort.

- Improved Aesthetics: Overmolding can add color contrast, textures, and soft-touch surfaces, enhancing the visual and tactile appeal of the product.

- Reduced Assembly Time and Costs: By combining materials in a single molding process, overmolding reduces the need for secondary operations and assembly, lowering manufacturing costs and improving production efficiency.

- Increased Durability: Overmolded parts often exhibit better wear resistance and durability, as the overmolded layer can provide additional protection to the underlying substrate.

Applications of Overmolding

- Automotive Industry: Overmolding is used to create components such as grips, handles, and seals that require a combination of rigidity and softness.

- Medical Devices: Medical instruments and devices benefit from overmolding by combining hard and soft materials for improved grip, comfort, and functionality.

- Consumer Electronics: Overmolding is employed to produce housings, grips, and protective coverings for electronic devices, offering both aesthetic and functional benefits.

- Tools and Handles: Power tools and hand tools often feature overmolded handles to provide a comfortable, non-slip grip and reduce user fatigue.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Overmolding Process Considerations

- Material Compatibility: Ensuring that the substrate and overmold materials are compatible is crucial for achieving a strong bond. Chemical compatibility and adhesion properties must be evaluated.

- Mold Design: The mold design must accommodate the overmolding process, considering factors such as material flow, cooling, and ejection.

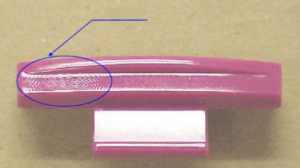

- Process Parameters: Precise control of process parameters, including temperature, pressure, and injection speed, is essential for achieving consistent results and preventing defects such as warping or delamination.

- Cycle Time: Overmolding can increase cycle time compared to standard injection molding, so process optimization is necessary to maintain efficiency.

Conclusion

Overmolding in injection molding is a versatile and valuable manufacturing technique that enables the creation of complex, multi-material components. By combining different materials in a single part, overmolding enhances functionality, aesthetics, and durability while reducing assembly time and costs. Its wide range of applications across various industries underscores its importance in modern manufacturing, making it a go-to solution for producing innovative and high-quality products.

Related Conten: Injection Molding Factory / Industrial Molds