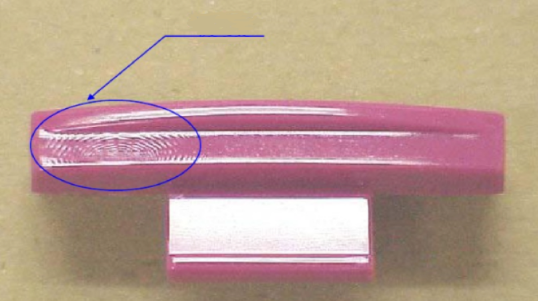

Splay, also known as silver streaks or flow lines, is a common defect in injection molded parts that appears as streaks or lines on the surface of the molded part. These imperfections are typically lighter in color and can significantly impact the aesthetic and structural integrity of the part. Understanding the causes of splay and how to prevent it is crucial for producing high-quality injection molded parts.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Primary Causes of Splay in Injection Molding

- Moisture in the Material:

- One of the most common causes of splay is the presence of moisture in the plastic material. When the material is heated, moisture turns into steam, which causes streaks on the surface of the part.

- High Melt Temperature:

- Excessive melt temperature can degrade the material, causing splay. Degraded material can release gases that result in splay on the surface of the part.

- Contaminated Material:

- Contamination of the material with foreign substances such as dust, dirt, or incompatible plastics can cause splay.

- Improper Drying:

- Many plastics, especially hygroscopic ones, require proper drying before processing. Inadequate drying can leave residual moisture, leading to splay.

- Poor Venting in the Mold:

- Inadequate venting can trap air and gases inside the mold cavity, causing splay as these gases are forced out during injection.

- High Injection Speed:

- High injection speeds can cause turbulence and trap air in the material flow, leading to splay.

- Inconsistent Material Flow:

- Irregular flow of material due to inconsistent heating or mechanical issues in the injection molding machine can cause splay.

- Degraded Resin:

- Using recycled or degraded resin can introduce contaminants and gases that cause splay.

Preventing Splay in Injection Molding

- Proper Material Drying:

- Ensure materials are adequately dried according to manufacturer specifications before processing. Use dehumidifying dryers for hygroscopic materials.

- Control Melt Temperature:

- Optimize melt temperature to avoid overheating and degradation of the plastic material.

- Clean Material Handling:

- Maintain clean handling and storage practices to prevent contamination of the plastic material.

- Optimize Venting:

- Ensure that the mold has adequate venting to allow trapped air and gases to escape during injection.

- Adjust Injection Speed:

- Reduce injection speed to minimize turbulence and air entrapment in the material flow.

- Regular Maintenance:

- Perform regular maintenance on the injection molding machine and mold to ensure consistent material flow and prevent mechanical issues.

- Use High-Quality Resin:

- Use high-quality, virgin resin whenever possible to minimize the risk of contamination and degradation.

- Monitor Processing Conditions:

- Continuously monitor and adjust processing conditions to ensure optimal performance and prevent splay.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Conclusion

Splay in injection molded parts can significantly impact the quality and appearance of the final product. By understanding the primary causes of splay, such as moisture in the material, high melt temperature, and poor venting, manufacturers can take proactive steps to prevent this defect. Implementing proper drying techniques, controlling melt temperature, ensuring clean material handling, optimizing venting, adjusting injection speeds, and using high-quality resin are essential strategies for minimizing splay and producing high-quality injection molded parts. Regular maintenance and monitoring of processing conditions further contribute to preventing splay and ensuring consistent production quality.

Related Conten: Quick Turn Injection Molding