Yes, PEEK (Polyether Ether Ketone) can be injection molded. PEEK is a high-performance engineering thermoplastic known for its excellent mechanical properties, chemical resistance, and thermal stability. It is used in demanding applications across various industries, including aerospace, automotive, medical, and electronics. Here’s a detailed look at PEEK injection molding:

Properties of PEEK

- High Strength and Stiffness:

- PEEK exhibits excellent tensile strength and stiffness, making it suitable for high-stress applications.

- Thermal Stability:

- PEEK can withstand high temperatures up to 250°C (482°F) continuously and short-term exposure up to 300°C (572°F).

- Chemical Resistance:

- Resistant to a wide range of chemicals, including acids, bases, and organic solvents.

- Wear and Abrasion Resistance:

- Offers superior wear resistance, making it ideal for applications involving sliding or moving parts.

- Low Flammability:

- PEEK has a high ignition temperature and low smoke emission, making it suitable for applications requiring flame resistance.

- Biocompatibility:

- Suitable for medical applications due to its biocompatibility and sterilizability.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

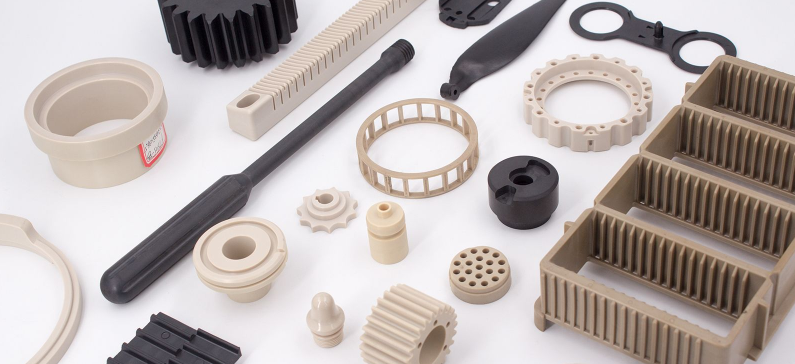

Applications of PEEK Injection Molding

- Aerospace:

- Components such as brackets, clips, and insulators that require high strength and thermal stability.

- Automotive:

- Parts like bearings, seals, and transmission components subjected to high temperatures and wear.

- Medical:

- Surgical instruments, implants, and dental devices due to its biocompatibility and sterilization capability.

- Electronics:

- Connectors, housings, and insulation parts requiring thermal and chemical resistance.

- Industrial:

- Pump components, valves, and gears for high-performance and chemically aggressive environments.

Injection Molding Process for PEEK

- Material Preparation:

- PEEK pellets must be thoroughly dried before processing to prevent moisture-related defects. Typical drying conditions are 150°C (302°F) for 3-4 hours.

- Injection Molding Machine Setup:

- Temperature Settings: Barrel temperatures are usually set between 350°C to 400°C (662°F to 752°F), with mold temperatures between 160°C to 200°C (320°F to 392°F).

- Injection Pressure: Typically ranges from 1000 to 2000 psi, depending on part geometry and material viscosity.

- Cooling Time: Adequate cooling time is essential to ensure part stability and prevent warpage.

- Molding Cycle:

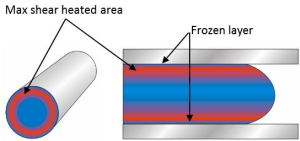

- Injection: Molten PEEK is injected into the mold cavity under high pressure.

- Cooling: The part cools and solidifies in the mold. Cooling time depends on part thickness and mold temperature.

- Ejection: Once solidified, the part is ejected from the mold.

- Post-Processing:

- Parts may require trimming to remove excess material or flash.

- Additional finishing processes, such as machining, annealing, or surface treatment, may be applied to achieve desired properties and dimensions.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Benefits of Using PEEK in Injection Molding

- High Performance: Excellent mechanical properties and thermal stability make PEEK suitable for demanding applications.

- Chemical Resistance: Resistant to many harsh chemicals, expanding its application range.

- Durability: High wear and abrasion resistance ensure long service life for components.

- Precision: Capable of producing high-precision parts with tight tolerances.

Considerations

- Processing Conditions:

- Consistent and precise processing conditions are crucial to prevent defects and ensure high-quality parts.

- Mold Design:

- Proper mold design, including adequate venting, cooling, and ejection systems, is essential to avoid defects and ensure part quality.

- Shrinkage:

- PEEK exhibits relatively low shrinkage, but design considerations must account for this to ensure dimensional accuracy.

- Cost:

- PEEK is a high-cost material, and its processing requires specialized equipment and conditions, making it suitable for high-value applications where performance justifies the cost.

Conclusion

PEEK is an exceptional material for injection molding, offering unparalleled mechanical properties, thermal stability, and chemical resistance. Its use is justified in high-performance and demanding applications across various industries. Proper material preparation, machine setup, and mold design are critical to achieving high-quality PEEK injection-molded parts. By carefully managing these factors, manufacturers can fully exploit PEEK’s benefits to produce durable and reliable components.

Related Conten: Rapid Injection Molding