Operating a CNC (Computer Numerical Control) machine requires a blend of technical knowledge and hands-on experience. These machines, essential in modern manufacturing, are used to create precision parts and components. This guide provides a comprehensive overview of how to operate a CNC machine, from initial setup to final production, ensuring you can make the most of this powerful technology.

Step 1: Understanding CNC Basics

- What is a CNC Machine?

- Definition: CNC machines are automated tools controlled by a computer program. They perform precise cutting, drilling, milling, and other operations on various materials.

- Types: Common types include CNC mills, lathes, routers, and plasma cutters.

- Components of a CNC Machine

- Control Panel: Interface for inputting commands and controlling the machine.

- Spindle: Rotates cutting tools or workpieces.

- Tool Changer: Automatically switches between different tools.

- Bed/Table: Surface where the workpiece is mounted.

- Axes: X, Y, and Z axes allow for three-dimensional movement.

Step 2: Safety Precautions

- Personal Protective Equipment (PPE)

- Safety Glasses: Protect your eyes from debris.

- Hearing Protection: CNC machines can be loud; use earplugs or earmuffs.

- Gloves and Aprons: Protect your hands and clothing.

- Machine Safety

- Emergency Stop: Know the location and operation of the emergency stop button.

- Machine Guarding: Ensure all guards are in place to prevent accidents.

- Work Area: Keep the area clean and free of obstructions.

Step 3: Preparing the CNC Machine

- Setting Up the Machine

- Power On: Turn on the machine and let it initialize.

- Home the Machine: Move the machine to its home position to ensure it knows its exact location.

- Loading the Tooling

- Select Tools: Choose the appropriate tools for the job.

- Tool Installation: Securely install tools in the spindle or tool holder.

- Tool Calibration: Use a tool setter or manually calibrate the tool height.

- Mounting the Workpiece

- Secure the Material: Use clamps, vises, or vacuum tables to hold the workpiece in place.

- Set Work Coordinates: Define the starting point (work zero) for the CNC program.

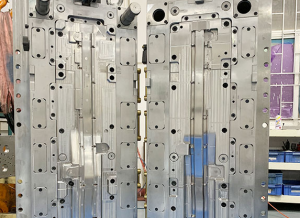

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Step 4: Creating and Loading the CNC Program

- CAD/CAM Software

- Design the Part: Use Computer-Aided Design (CAD) software to create a digital model of the part.

- Generate G-Code: Use Computer-Aided Manufacturing (CAM) software to convert the CAD model into G-code, the language CNC machines understand.

- Loading the Program

- Transfer the G-Code: Use a USB drive, network connection, or direct input to load the G-code into the CNC machine’s control panel.

- Program Verification: Run a simulation to verify the program’s accuracy and check for errors.

Step 5: Running the CNC Machine

- Dry Run

- Test Run: Perform a dry run without cutting material to ensure the machine follows the correct path.

- Adjustments: Make any necessary adjustments to the program or setup.

- Start the Machining Process

- Begin Cutting: Start the machine and monitor the cutting process.

- Feed Rate and Speed: Adjust the feed rate and spindle speed as needed for optimal performance.

- Monitoring

- Watch for Issues: Keep an eye on the machine for any signs of problems, such as unusual noises or tool wear.

- Coolant and Lubrication: Ensure the machine’s coolant and lubrication systems are functioning correctly.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Step 6: Finishing and Inspection

- Part Removal

- Stop the Machine: Ensure the machine is fully stopped before removing the part.

- Deburr and Clean: Remove any burrs or sharp edges from the part.

- Inspection

- Quality Control: Use measuring tools such as calipers, micrometers, and gauges to inspect the part for accuracy.

- Make Adjustments: If necessary, make adjustments to the program or setup for future runs.

Conclusion

Operating a CNC machine involves understanding its components, following safety protocols, preparing the machine and workpiece, creating and loading the CNC program, and carefully running and monitoring the machining process. With practice and attention to detail, you can efficiently operate a CNC machine and produce high-quality parts.

Related Conten: CNC Custom Molders Corp