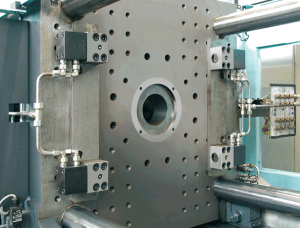

Hiding screws in an injection molded part can improve the aesthetic appeal and functionality of the product. Here are some common techniques used to achieve this:

- Snap-Fit Connections:

- Use snap-fit connections instead of screws. These are integrated into the design of the part and allow for easy assembly and disassembly without visible fasteners.

- Covers and Caps:

- Design the part with covers or caps that can be snapped or slid into place over the screws after assembly.

- Plug Inserts:

- Use matching plugs or inserts that fit into the screw holes, hiding the screws from view. These can be designed to blend seamlessly with the surface of the part.

- Recessed Screw Holes:

- Create recessed areas where the screws are installed. These recessed areas can then be filled with a matching material or a separate cap to conceal the screws.

- Sonic Welding or Heat Staking:

- Use ultrasonic welding or heat staking to join parts together. This method eliminates the need for screws altogether.

- Screw Boss Design:

- Design the screw bosses so that the screws are hidden from view. This can be achieved by placing the bosses inside the part or behind other features.

- Living Hinges:

- Utilize living hinges to create doors or flaps that can hide screws. These hinges are integrated into the part and can be opened and closed as needed.

- Adhesive Bonding:

- Use adhesives instead of screws for assembly. This can provide a clean look with no visible fasteners.

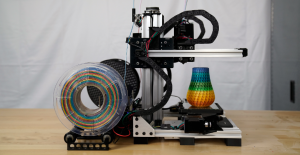

- Two-Shot Molding:

- Use two-shot molding to create parts with built-in covers that can be snapped into place to hide screws.

Your Partner in Custom Injection Molding

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

By carefully considering the design and assembly process, you can effectively hide screws in your injection molded parts, enhancing both the functionality and appearance of your product.

Related Conten: Custom Molders Corp