Injection molding is renowned for its high precision and ability to produce complex parts with tight tolerances. The precision of injection molding depends on various factors, including the quality of the mold, the material used, the machine specifications, and the control of processing parameters. Here’s a detailed look at the precision capabilities of injection molding:

Factors Affecting Precision in Injection Molding

- Mold Quality

- Machining Accuracy: The precision of the mold itself is critical. High-quality molds are manufactured using advanced CNC machining, EDM (Electrical Discharge Machining), and other techniques to achieve fine details and tight tolerances.

- Material of Mold: Using high-grade tool steel or aluminum can improve mold durability and maintain dimensional accuracy over long production runs.

- Material Properties

- Shrinkage Rates: Different materials have varying shrinkage rates, affecting the final part dimensions. Understanding and compensating for material shrinkage is crucial for precision.

- Consistency: Using high-quality, consistent materials reduces variability in the molding process.

- Machine Specifications

- Clamping Force: Adequate clamping force ensures the mold remains closed without flash during injection.

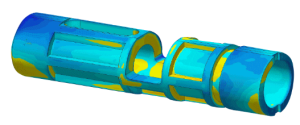

- Injection Pressure and Speed: Precise control of injection pressure and speed is necessary to fill the mold accurately and consistently.

- Temperature Control: Maintaining consistent temperatures in the barrel, nozzle, and mold helps ensure uniform material flow and solidification.

- Processing Parameters

- Cycle Time: Optimized cycle times ensure consistent cooling and solidification, reducing part variability.

- Injection Timing: Precise control of injection timing ensures the mold is filled correctly every cycle.

- Quality Control and Monitoring

- In-Process Monitoring: Using sensors and software to monitor and control the injection molding process in real time can detect and correct deviations immediately.

- Post-Process Inspection: Regular inspection of parts using techniques like coordinate measuring machines (CMMs) ensures that parts meet the required tolerances.

Typical Precision Levels

- Dimensional Tolerances: Injection molding can achieve dimensional tolerances within ±0.005 inches (±0.127 mm) for standard applications. High-precision molds and processes can achieve even tighter tolerances, such as ±0.001 inches (±0.025 mm) or better.

- Consistency: High-quality injection molding processes can produce parts with minimal variation from one cycle to the next, often achieving part-to-part consistency within a few microns.

Examples of High-Precision Injection Molding

- Medical Devices: Components for medical devices, such as syringes, implantable devices, and diagnostic equipment, often require extremely tight tolerances and high precision.

- Electronics: Housing and internal components for electronics need precise fits and minimal variability to ensure proper assembly and function.

- Automotive: Many automotive parts, especially those related to safety and engine performance, require high precision to meet stringent industry standards.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Achieving Precision in Injection Molding

- Design for Manufacturability (DFM)

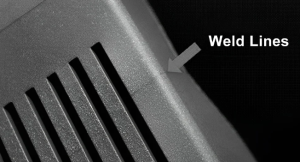

- Optimized Part Design: Design parts with uniform wall thicknesses, appropriate draft angles, and minimized undercuts to ensure better moldability and precision.

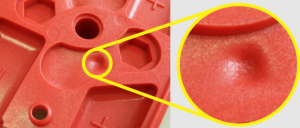

- Simulation Tools: Use software tools for mold flow analysis to predict and mitigate potential issues before production begins.

- Advanced Mold Making

- High-Precision Machining: Invest in high-quality machining processes and equipment to produce molds with precise dimensions and fine details.

- Regular Maintenance: Maintain and regularly inspect molds to ensure they remain within specified tolerances over their lifespan.

- Process Control

- Automated Systems: Utilize automated systems to control and monitor the injection molding process, ensuring consistent conditions and immediate correction of any deviations.

- Training and Expertise: Ensure operators and technicians are well-trained and knowledgeable about the process and equipment.

Conclusion

Injection molding is capable of producing highly precise parts with tight tolerances and consistent quality. Achieving this precision requires attention to mold design and construction, material selection, machine specifications, and meticulous control of processing parameters. When properly managed, injection molding can reliably produce parts for demanding applications in various industries, including medical, electronics, and automotive sectors.

Related Conten: Custom Molders Corp