Bubbles in injection molded parts are a common defect that can compromise the appearance and structural integrity of the final product. Understanding the causes of bubbles and implementing corrective actions can help eliminate this issue. Here are the primary causes of bubbles in injection molding and how to address them:

Causes of Bubbles in Injection Molding

- Moisture in the Material

- Cause: Hygroscopic materials (e.g., nylon, polycarbonate) absorb moisture from the air. During molding, this moisture can vaporize, forming bubbles.

- Solution: Properly dry the plastic resin before molding using a drying system. Ensure that the drying parameters (time, temperature, and airflow) are appropriate for the specific material.

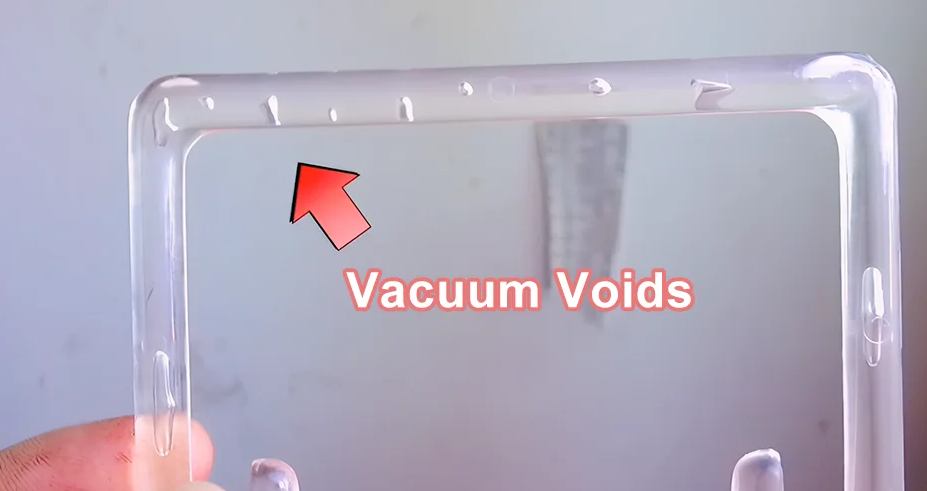

- Air Entrapment

- Cause: Air can get trapped in the mold cavity if the mold is not vented properly or if the injection speed is too high, preventing air from escaping.

- Solution: Improve mold venting by adding or enlarging vents in the mold cavity. Optimize the injection speed and pressure to allow air to escape before the cavity is filled.

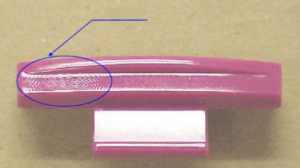

- Incorrect Injection Molding Parameters

- Injection Speed: Too high injection speed can trap air, while too low speed might not pack the material properly.

- Injection Pressure: Insufficient pressure may not adequately pack the material, leading to bubbles.

- Solution: Adjust injection speed and pressure settings to ensure proper filling and packing of the mold cavity.

- Material Degradation

- Cause: Excessive heat or prolonged residence time in the barrel can degrade the material, causing it to release gases that form bubbles.

- Solution: Set appropriate barrel temperatures to prevent overheating and reduce the residence time of the material in the barrel.

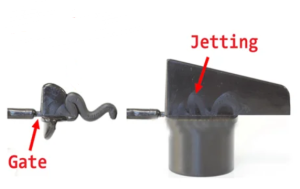

- Mold Design Issues

- Thick Sections: Thicker areas in the part can cool slowly, trapping gas and forming bubbles.

- Improper Gate Location: Poorly located gates can lead to uneven filling and air entrapment.

- Solution: Design parts with uniform wall thickness and avoid thick sections. Optimize gate location and design to ensure even filling and air escape.

- Contamination

- Cause: Contaminants in the material, such as dirt, oil, or other foreign substances, can lead to bubble formation.

- Solution: Ensure the material is clean and free from contaminants. Regularly clean the hopper, barrel, and other equipment parts that come in contact with the material.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Troubleshooting and Corrective Actions

- Dry the Material Properly

- Use a desiccant dryer to dry the material to the manufacturer’s recommended moisture level.

- Check and maintain the dryer regularly to ensure it is functioning correctly.

- Optimize Molding Parameters

- Injection Speed: Reduce the injection speed to prevent air entrapment. Use a multi-stage injection profile if necessary.

- Injection Pressure: Increase the injection pressure to ensure the mold cavity is fully packed.

- Back Pressure: Adjust the back pressure during screw recovery to ensure uniform material consistency.

- Improve Mold Venting

- Add or enlarge vents in critical areas of the mold to allow trapped air to escape.

- Ensure that the vents are clean and free from blockages.

- Use Vacuum Assist

- For parts with complex geometries or high likelihood of air entrapment, consider using vacuum-assisted molding to remove air from the mold cavity before injection.

- Monitor and Adjust Barrel Temperatures

- Ensure that the barrel temperatures are set according to the material specifications to prevent overheating and degradation.

- Monitor the temperature profiles regularly and make adjustments as needed.

- Modify Part and Mold Design

- Redesign parts to have uniform wall thickness and avoid thick sections where possible.

- Optimize gate locations to ensure even filling and reduce the risk of air entrapment.

Summary of Actions

| Issue | Cause | Solution |

|---|---|---|

| Moisture | Hygroscopic materials absorbing moisture | Properly dry the resin before molding |

| Air Entrapment | Insufficient venting, high injection speed | Improve mold venting, optimize injection speed and pressure |

| Molding Parameters | Incorrect speed, pressure, back pressure | Adjust injection speed, pressure, and back pressure |

| Material Degradation | Excessive heat, long residence time | Set appropriate barrel temperatures, reduce residence time |

| Mold Design | Thick sections, improper gate location | Redesign part for uniform thickness, optimize gate location |

| Contamination | Foreign substances in material | Clean material and equipment, ensure material purity |

Conclusion

Bubbles in injection molded parts can be caused by a variety of factors, including moisture in the material, air entrapment, incorrect molding parameters, material degradation, mold design issues, and contamination. By addressing these issues through proper drying, optimizing molding parameters, improving mold venting, monitoring temperatures, and ensuring clean materials and equipment, you can effectively reduce or eliminate bubbles in injection molded parts.

Related Conten: https://www.m-dtg.com/service/plastic-assembly-decoration/