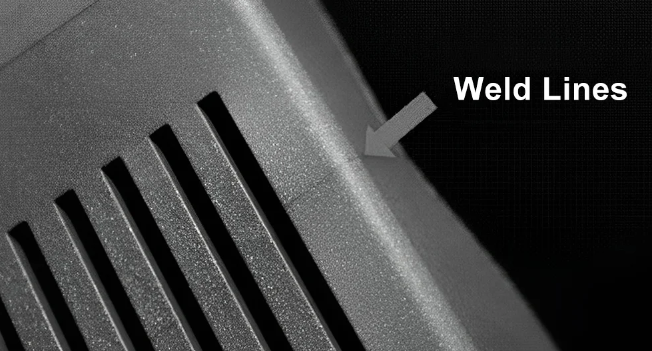

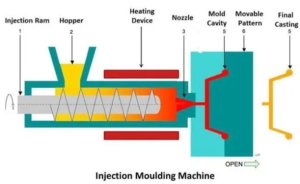

Injection molding is a sophisticated manufacturing process used to produce complex plastic parts with high precision. One common defect encountered in this process is the formation of weld lines. Weld lines, also known as knit lines or meld lines, occur when two or more flow fronts of molten plastic meet and solidify, resulting in a visible line or weak spot on the finished part. These lines can compromise both the aesthetic and structural integrity of the molded product. Understanding the causes of weld lines is essential for improving product quality and ensuring the reliability of molded parts.

Causes of Weld Lines in Injection Molding

1. Mold Design Issues

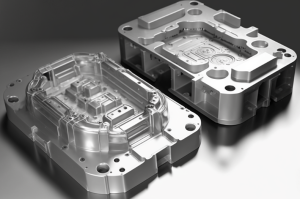

- Complex Geometry: Parts with complex shapes, multiple gates, or intricate features can cause multiple flow fronts to meet, resulting in weld lines.

- Gate Location: Improper gate placement can lead to uneven filling and the convergence of flow fronts, forming weld lines. Strategic gate placement is crucial for minimizing this defect.

- Inadequate Venting: Poor venting can trap air in the mold, causing interruptions in the flow of molten plastic and leading to the formation of weld lines.

2. Material Properties

- Viscosity of the Material: High-viscosity materials may not flow smoothly, increasing the likelihood of weld lines forming when flow fronts meet.

- Material Additives: Additives such as fillers or colorants can affect the flow characteristics of the molten plastic, contributing to weld line formation.

3. Processing Parameters

- Injection Speed: Slow injection speeds can cause the molten plastic to cool and solidify prematurely, leading to weld lines where flow fronts converge. Optimizing injection speed can help achieve a smooth flow.

- Injection Pressure: Low injection pressure can result in incomplete filling of the mold, causing flow fronts to meet and form weld lines. Maintaining appropriate injection pressure is important for preventing this defect.

- Melt Temperature: Inadequate melt temperature can cause the plastic to solidify too quickly, leading to weld lines. Ensuring the plastic is heated to the optimal temperature can help achieve a uniform flow.

4. Cooling Rate

- Uneven Cooling: Differential cooling rates within the mold can cause flow fronts to cool and solidify at different times, leading to the formation of weld lines.

- Mold Temperature: The temperature of the mold itself can affect how the plastic flows and cools. Uneven mold temperature can result in weld lines as different sections of the part solidify at different rates.

5. Flow Path and Material Flow

- Flow Front Convergence: When multiple flow fronts converge, the molten plastic may not fuse properly, leading to weld lines. This is particularly common in parts with multiple gates or complex geometries.

- Flow Interruption: Any interruption or obstruction in the flow of molten plastic can cause flow fronts to meet in a way that forms weld lines.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Solutions to Prevent Weld Lines

1. Optimize Mold Design

- Strategic Gate Placement: Position gates to ensure smooth and even filling of the mold cavity, minimizing the convergence of flow fronts.

- Improve Venting: Incorporate adequate venting to allow trapped air to escape and ensure uninterrupted flow of molten plastic.

- Simplify Geometry: Design parts with simpler geometries to reduce the likelihood of multiple flow fronts converging.

2. Control Material Properties

- Select Appropriate Materials: Choose materials with suitable flow characteristics to ensure smooth and even filling of the mold.

- Optimize Additives: Use additives that do not adversely affect the flow properties of the molten plastic.

3. Adjust Processing Parameters

- Increase Injection Speed: Set the injection speed to an optimal level to prevent premature solidification and ensure smooth flow.

- Maintain Injection Pressure: Ensure adequate injection pressure to achieve complete filling and minimize the formation of weld lines.

- Optimize Melt Temperature: Heat the plastic to the appropriate temperature to ensure it flows smoothly and does not solidify prematurely.

4. Control Cooling Rate

- Ensure Even Cooling: Maintain uniform cooling rates across the mold to prevent differential solidification and reduce the formation of weld lines.

- Control Mold Temperature: Keep the mold temperature consistent to promote even flow and cooling of the molten plastic.

5. Improve Flow Path and Material Flow

- Minimize Flow Front Convergence: Design parts and gates to reduce the likelihood of multiple flow fronts meeting.

- Ensure Uninterrupted Flow: Avoid interruptions or obstructions in the flow path of the molten plastic to prevent weld lines.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

Conclusion

Weld lines in injection molding can compromise both the aesthetic and structural quality of molded parts. By understanding the causes and implementing appropriate solutions, manufacturers can minimize the occurrence of weld lines and ensure high-quality, reliable products. Optimizing mold design, controlling material properties, adjusting processing parameters, ensuring even cooling rates, and improving the flow path are key steps to preventing weld lines. Addressing these factors not only enhances product quality but also improves overall manufacturing efficiency and consistency.

Related Conten: Custom Plastic Fabrication