Yes, you can CT scan metal injection molded (MIM) components. Computed tomography (CT) scanning is a valuable non-destructive testing (NDT) technique used to inspect and analyze the internal and external features of MIM parts. Here’s how it works and its benefits:

How CT Scanning Works

- Imaging Process:

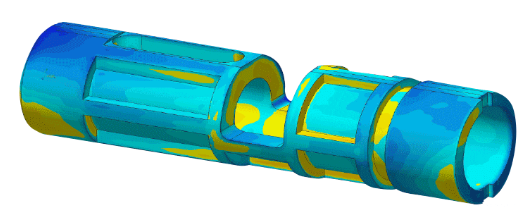

- A CT scanner uses X-rays to create cross-sectional images of the part from multiple angles.

- These images are then reconstructed by a computer to form a 3D model of the internal and external structure of the component.

- Data Analysis:

- The 3D model can be analyzed to detect defects such as porosity, cracks, voids, and inclusions.

- Dimensional measurements can be taken to verify the part against the original CAD model.

Benefits of CT Scanning for MIM Components

1. Non-Destructive Testing:

- CT scanning is non-destructive, meaning the part is not damaged during inspection.

- This is crucial for high-value or complex parts where destructive testing would be impractical or costly.

2. Internal and External Inspection:

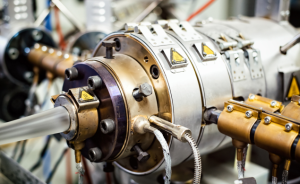

- CT scanning allows for the inspection of internal features that are not accessible by traditional inspection methods.

- Both the external geometry and internal structure can be evaluated in a single scan.

3. Detection of Defects:

- CT scanning can detect and quantify internal defects such as porosity, voids, and inclusions that may affect the part’s performance.

- Early detection of defects helps in improving the quality and reliability of MIM components.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

4. Dimensional Analysis:

- The 3D data obtained from CT scans can be used for precise dimensional analysis.

- This helps in verifying the part dimensions against the design specifications and ensuring compliance with tolerances.

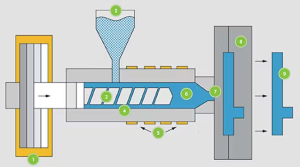

5. Process Optimization:

- By identifying and analyzing defects and dimensional deviations, manufacturers can optimize the MIM process.

- This leads to improved part quality and reduced scrap rates.

Applications in Various Industries

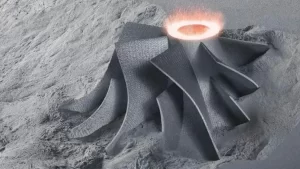

1. Automotive:

- Inspection of complex MIM parts used in engines, transmissions, and fuel systems for defects and dimensional accuracy.

2. Medical Devices:

- Ensuring the integrity and precision of critical components like surgical instruments and implants.

3. Aerospace:

- Verifying the quality of high-strength, lightweight components used in aerospace applications.

4. Consumer Electronics:

- Inspecting intricate parts used in electronic devices for internal defects and dimensional conformance.

As a leading mold injection manufacturer in China, we deliver superior molds for various industries. Our state-of-the-art facilities and expert team ensure top-notch quality and timely delivery. Contact us now for a competitive quote!

References

- Zeiss: Discusses the use of CT scanning for quality control in MIM parts.

- Volume Graphics: Provides insights into the benefits of CT scanning for MIM components.

- Yxlon: Offers information on how CT scanning is applied in the inspection of metal parts.

CT scanning is an effective method for inspecting MIM components, offering detailed insights into both internal and external features, which is crucial for ensuring high-quality and reliable parts.

Related Conten: https://www.m-dtg.com/landing-page/high-quality-prototype-plastic-injection-molding/