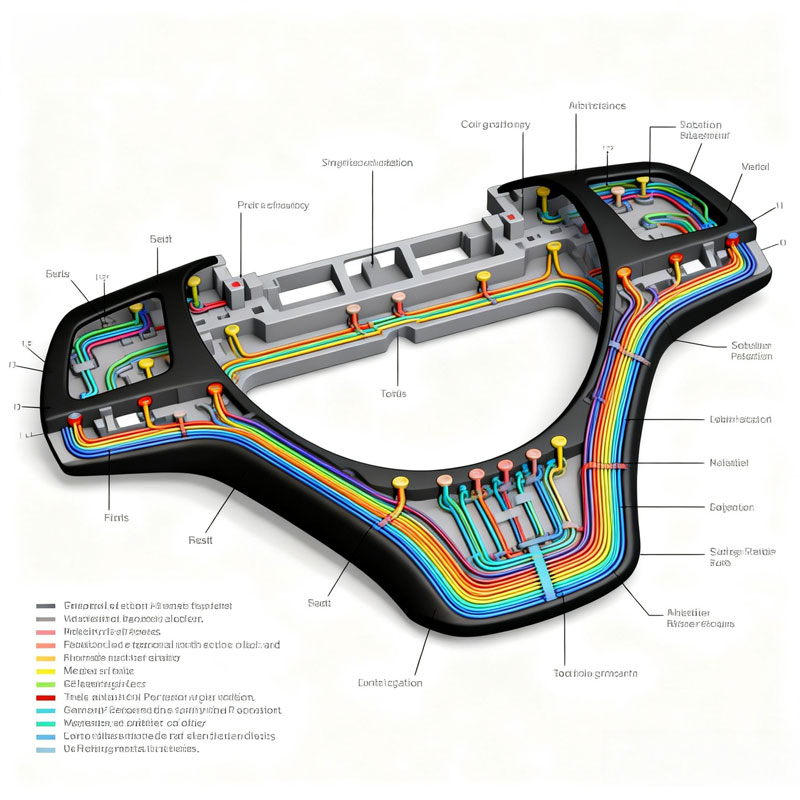

Auto Steering Wheel Trim Plate – Injection Molding Automotive Parts for Interior Applications

Product Overview

The Auto Steering Wheel Trim Plate – Custom Injection Molding is a precision-engineered component designed specifically for injection molding automotive parts used in modern vehicle interiors. Typically manufactured using durable and lightweight materials such as ABS, PC+ABS, or reinforced Nylon, this component is optimized for strength, aesthetic consistency, and long-term reliability.

In our experience, automotive interior components must balance appearance with performance. Therefore, this trim plate is widely used in passenger cars, electric vehicles, and commercial vehicles where consistent quality and ergonomic design are essential. From our perspective, automotive injection molding remains the most cost-effective and scalable solution for producing complex interior parts with tight tolerances.

Pain Points

- Inconsistent dimensions causing assembly difficulties in steering wheel modules

- Poor material selection leading to cracking, deformation, or heat resistance issues

- Warping, shrinkage, or sink marks affecting appearance and functionality

- Uneven surface finishing, weak coating adhesion, or color inconsistency

It is evident that many buyers struggle when sourcing injection molding car parts due to unstable quality and lack of technical support from inexperienced suppliers.

Our Solutions

- Comprehensive DFM analysis to minimize warpage and shrinkage

- Material engineering support to select ABS, PC+ABS, PA6, or PA66 depending on performance needs

- Optimized gate design and cooling systems for stable and consistent molding

- Industry-standard QC inspections including CMM, visual checks, and functional testing

- Multiple surface finishing options such as texture, painting, polishing, and laser engraving

We believe that proactive engineering involvement significantly improves product consistency. Consequently, our approach ensures reliable results compared with conventional automotive injection molding companies.

Manufacturing Capabilities

- Plastic Injection Molding for automotive interior components

- In-house Mold Design & Fabrication

- Insert Molding and Overmolding solutions

- Ultrasonic Welding and mechanical assembly

- Surface finishing including painting, plating, and laser marking

Industry practice indicates that vertical integration is crucial for maintaining quality. As one of the experienced automotive injection molding suppliers, we consistently control every stage of production.

Industries Served

- Automotive Interior Components

- Smart Home Devices

- Consumer Electronics

- Home Appliances

- Medical Device Housings

Notably, plastic injection molding automotive parts like steering wheel trim plates are especially suitable for applications requiring durability, precision, and aesthetic appeal.

Technical Specifications

Materials

- ABS, PC/ABS, PP, PC, POM, Nylon 6/66, PMMA, ASA, PVC, TPE, TPU, PPS, PEI, PSU

Surface Finishing

- Matte, Texture, Polishing, Painting, Plating, Laser Engraving, Printing

Mold Material

- S136H, 718H, NAK80, P20, H13

Drawing Format

- .stp / .step / .igs / .stl / .dwg / .pdf

Color

- All PMS colors available

Tolerance

- According to SJ/T10628-1995 standards, Class 3 or per customer request

Mold Life

- 100,000 – 500,000 shots

Packaging

- Bulk, Poly Bag, Bubble Bag, Carton, Custom Packaging

Why Choose Us

- 20+ years of experience in automotive injection molding

- ISO 9001:2015 certified manufacturing facility

- Complete in-house mold making workshop

- Strict QC system: IQC → IPQC → FQC → OQC

- Fast lead time: samples in 7–10 days, mass production in 15–25 days

- Flexible MOQ supporting both low and high-volume projects

From our perspective, reliability and transparency are what truly differentiate leading automotive injection molding companies from the rest.

Production Flow

- DFM Analysis

- Mold Design

- Mold Manufacturing

- T1 Sample Testing

- Mold Optimization

- Mass Production

- QC Inspection

- Packing & Shipping

Internal Links

Learn more about our services:

Plastic Injection Molding

Explore our manufacturing experience:

Case Studies

Understand our cooperation steps:

Trade Process

Call to Action

Ready to Start Your Custom Automotive Injection Molding Project?

It makes sense to work with a proven partner who understands real-world injection moulding examples in the automotive industry. Contact us today to receive a fast, accurate quotation.

FAQ

What tolerance can you achieve for automotive injection molding parts?

Typically ±0.05mm. For precision steering wheel trim components, tolerance can reach ±0.02mm depending on part geometry and material.

Which material is best for steering wheel trim plates?

PC+ABS is commonly used due to its impact resistance, heat stability, and excellent surface finish. However, material selection depends on performance and cost requirements.

How long does mold manufacturing take?

Normally 25–35 days, depending on mold complexity and surface finishing requirements.

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|