Injection blow molding (IBM) is a manufacturing process used to produce hollow plastic parts, such as bottles and containers, in a high-volume and cost-effective manner. This process combines the principles of injection molding and blow molding, making it particularly suitable for creating small, precise, and high-quality hollow objects.

Key Stages of Injection Blow Molding

- Injection Molding Stage

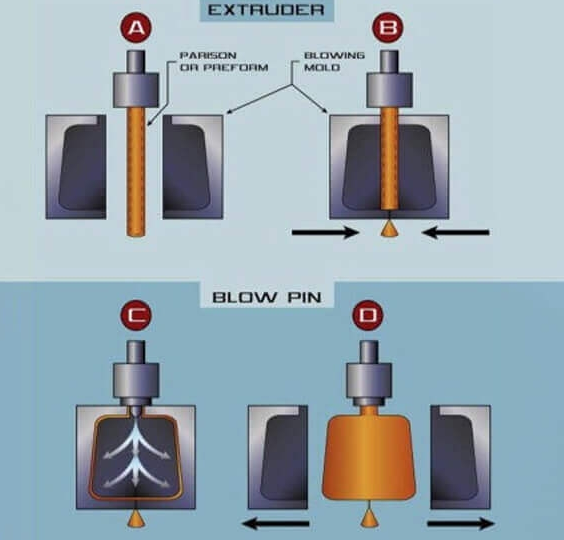

- Preform Creation: In this initial stage, a preform (or parison) is created by injecting molten plastic into a multi-cavity mold. The preform resembles a test tube with a threaded neck and is precisely formed to have the correct shape and material distribution for the final product.

- Blow Molding Stage

- Transfer to Blow Mold: The preforms are transferred (often while still warm) to a blow mold.

- Blowing: Air is blown into the preform, causing it to expand and conform to the shape of the blow mold cavity. This forms the final hollow product, ensuring uniform wall thickness and precise dimensions.

- Cooling and Ejection

- Cooling: The blown product is cooled within the mold to solidify its shape.

- Ejection: The finished product is ejected from the blow mold, ready for any post-processing or assembly.

[elementor-template id=”4330″]

Key Components of Injection Blow Molding Equipment

- Injection Mold

- Contains cavities for forming the preforms, usually designed to accommodate multiple preforms per cycle to increase efficiency.

- Blow Mold

- Contains cavities that shape the final product by inflating the preform. This mold is typically designed for optimal cooling and precise shaping.

- Injection Blow Molding Machine

- A specialized machine that integrates both injection molding and blow molding processes. It typically includes injection units, blow molding stations, and a transfer system to move preforms between these stages.

Advantages of Injection Blow Molding

- Precision and Consistency

- IBM produces high-quality parts with consistent wall thickness and precise dimensions, making it ideal for products requiring tight tolerances.

- Material Efficiency

- The process minimizes waste by efficiently using material, especially compared to traditional blow molding methods that might involve more trimming and excess plastic.

- High Production Rates

- IBM is suitable for large-scale production runs, offering high throughput and repeatability.

- Smooth Surface Finish

- The parts produced have excellent surface finishes, often eliminating the need for secondary finishing processes.

Applications of Injection Blow Molding

- Pharmaceutical Containers

- Production of small, precise bottles for medications, eyedrops, and other pharmaceutical applications.

- Cosmetic Containers

- Manufacturing of high-quality bottles and jars for cosmetics, perfumes, and personal care products.

- Food and Beverage Packaging

- Production of containers for beverages, condiments, and other food products that require precise, hygienic, and aesthetically pleasing packaging.

- Household and Industrial Products

- Creation of containers and bottles for cleaning products, oils, and other household or industrial liquids.

[elementor-template id=”4331″]

Example of Injection Blow Molding Process

Consider the production of plastic bottles for a pharmaceutical company:

- Injection Molding Stage:

- Molten plastic, such as PET or HDPE, is injected into a mold to create preforms. These preforms are precisely shaped with the required neck finish for the final bottle.

- Transfer to Blow Mold:

- The preforms are transferred, often via a rotating wheel or robotic arm, to the blow mold cavities.

- Blow Molding Stage:

- Air is injected into the preforms, causing them to expand and take the shape of the blow mold cavities, forming the final bottle shape.

- Cooling and Ejection:

- The bottles are cooled within the blow mold, ensuring they retain their shape and structural integrity. The finished bottles are then ejected and moved to packaging or further processing.

Conclusion

Injection blow molding is a versatile and efficient process for producing high-quality, precise, and consistent hollow plastic parts. By combining injection molding and blow molding techniques, IBM offers significant advantages in terms of material efficiency, surface finish, and production rates, making it ideal for applications in the pharmaceutical, cosmetic, food and beverage, and household product industries. Properly designed molds and machines are crucial to maximizing the benefits of this process and ensuring the production of top-quality parts.

Related Conten: Plastic Injection Molding / Prototype Manufacturing

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|