Introduction to Low-Volume Plastic Injection Molding

In today’s fast-paced market, businesses need manufacturing solutions that are not only cost-effective but also capable of delivering high-quality products in a timely manner. Low-volume plastic injection molding offers a perfect balance of affordability, efficiency, and precision, especially for companies requiring small-scale production. It is a flexible, reliable solution for companies needing high-quality plastic components in quantities that don’t justify full-scale manufacturing.

This method is ideal for producing small batches of plastic parts, often used for product prototypes, limited-run items, or niche applications. Whether for consumer electronics, medical devices, or automotive parts, low-volume injection molding provides custom solutions tailored to specific needs while ensuring fast production times, lower costs, and superior quality.

Why Choose Low-Volume Plastic Injection Molding?

Cost-Effectiveness Without Compromising Quality

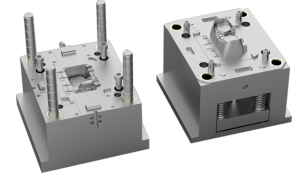

For companies aiming to reduce overall manufacturing costs, low-volume plastic molding presents an excellent opportunity. Traditional large-scale manufacturing involves significant investments in tooling, machinery, and labor. However, short-run injection molding dramatically lowers initial costs by using simpler, more cost-efficient molds.

Furthermore, as opposed to high-volume manufacturing, this process eliminates the need for mass inventory and storage, reducing unnecessary overhead costs. Companies benefit from producing only what they need when they need it, which directly reduces overall production expenses.

Timely Delivery – Meeting Tight Deadlines

An essential concern for businesses is meeting deadlines. With small-run injection molding, production times are significantly shorter, making it ideal for companies that require fast delivery and want to bring products to market quickly. Rapid prototyping, small batch production, and efficient turnaround times ensure that businesses can meet their schedules without delay.

Moreover, the flexibility of plastic injection molding means it’s possible to adjust production schedules quickly, accommodating urgent requirements or last-minute changes. This ensures your supply chain remains stable, even under tight timelines.

Case Study: Successful Collaboration with an African Beverage Company

To demonstrate the practical advantages of low-volume plastic molding, let’s consider a real-world example of a recent collaboration with a beverage company in Nigeria. The company, ABC Beverages, sought a reliable supplier for custom plastic bottle caps. They faced challenges such as frequent quality issues with their previous suppliers, long lead times, and higher-than-expected costs.

DTG stepped in with an effective solution. We provided custom plastic injection molding services, meeting their specific requirements for bottle caps, including high durability, precision, and a custom design to match their branding. The production volume was relatively small, but our ability to deliver high-quality results was key.

Key benefits achieved:

- Quality Assurance: Our molds met stringent EU and US standards, ensuring the final product was durable and fit for purpose.

- On-Time Delivery: Despite initial concerns, we were able to deliver the caps on schedule, significantly reducing downtime for the beverage company.

- Cost Reduction: By utilizing low-volume production, ABC Beverages saved on tooling and material costs, helping them maintain budget control.

- Customer Satisfaction: The product quality exceeded their expectations, and they praised our efficient communication and project management, which included English-language support for ease of collaboration.

Key Advantages of Low-Volume Plastic Injection Molding

1. High Precision and Customization

One of the most significant benefits of low-volume plastic injection molding is its ability to produce high-precision parts that meet your unique specifications. The process allows for the customization of parts in terms of design, material choice, and functionality. This is especially valuable in industries like medical devices, consumer electronics, and automotive where precision and reliability are paramount.

2. Reduced Risk and Flexibility

Low-volume molding is ideal for companies wishing to test new products or prototypes before committing to large-scale manufacturing. This gives businesses the flexibility to make adjustments based on real-world feedback, helping to avoid costly mistakes and minimize financial risks.

3. Scalability

If demand for a product increases, small-run injection molding can easily scale up to accommodate larger production volumes. As your business grows, you can expand your production while maintaining high quality and consistency.

FAQs about Low-Volume Plastic Injection Molding

Q1: What industries can benefit from low-volume plastic molding?

A1: Low-volume plastic molding is highly adaptable and can be used across various industries, including consumer electronics, automotive, medical devices, packaging, and household products. It is particularly beneficial for businesses that require high-precision components in small quantities or those looking to prototype or test a new product.

Q2: How does low-volume molding compare to high-volume molding in terms of cost?

A2: While low-volume molding typically involves a higher per-unit cost than high-volume molding, the overall cost is lower due to reduced tooling expenses, less material waste, and the absence of long-term inventory storage. It is a more cost-effective solution for small batches or prototypes.

Q3: How long does it take to produce parts using low-volume injection molding?

A3: The production timeline for low-volume plastic injection molding is significantly shorter than large-scale manufacturing. The time required can vary depending on the complexity of the parts and the mold design, but typically, parts can be produced in a matter of days to a few weeks, allowing for faster product launches.

Conclusion: Unlock the Benefits of Low-Volume Plastic Molding for Your Business

In conclusion, low-volume plastic injection molding offers businesses the opportunity to produce high-quality, custom parts with shorter lead times, lower costs, and greater flexibility. Whether you are looking to prototype a new product, produce a limited run, or enter a new market, this method provides a cost-effective and reliable solution.

To learn more about how our plastic injection molding services can benefit your business, reach out today and discuss how we can meet your unique production needs.