What is Low-Volume Plastic Molding?

Low-volume plastic molding, also known as short run injection molding or small run injection molding, is a manufacturing process designed for producing plastic parts in small quantities, usually ranging from tens to a few thousand units. Unlike traditional mass production molding, low-volume plastic molding is ideal for businesses that need rapid prototypes, custom parts, or small batch production runs.

This method is widely used in industries such as consumer electronics, medical devices, automotive parts, and home goods, where customization and speed are essential. Whether you’re testing a new product design or need parts for a limited release, low volume plastic molding ensures that you can produce high-quality components without the high costs associated with large-scale manufacturing.

The Principle Behind Low-Volume Injection Molding

The principle behind low-volume plastic molding shares similarities with traditional injection molding, but it focuses on smaller batch sizes, making it more cost-effective for low-run production. Here’s a brief overview of how the process works:

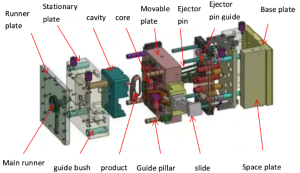

- Mold Design and Manufacturing: For short run injection molding, the mold designs are typically less complex, which reduces costs and lead times. These molds are often made from simpler materials compared to the ones used in mass production.

- Plastic Material Heating: Plastic pellets are fed into an injection molding machine, where they are melted to a liquid state.

- Injection and Cooling: The molten plastic is injected into the mold cavity and cooled to solidify into the desired shape.

- Part Removal and Finishing: After cooling, the parts are removed from the mold, and any additional finishing steps, such as trimming, polishing, or painting, are performed.

This process makes small run injection molding ideal for producing high-quality, customized plastic parts with fast turnaround times and low upfront costs.

Benefits of Low-Volume Injection Molding

Low-volume injection molding offers a range of benefits that make it the go-to choice for many industries looking for custom, small-batch production. Here are some of the top advantages:

1. Cost-Effectiveness

Compared to large-scale production, low-volume plastic molding allows businesses to save on costs. The mold designs are simpler, which reduces manufacturing expenses, making it an ideal solution for companies with smaller budgets or limited product quantities. Additionally, this method helps reduce waste, further improving cost efficiency.

2. Fast Turnaround Time

One of the key benefits of short run injection molding is the rapid production cycle. Since the molds are simpler and smaller quantities are being produced, the production time is significantly shorter than mass production. This allows businesses to move quickly from concept to prototype and to finalize products faster.

3. Flexibility in Production

Low-volume molding provides greater flexibility than traditional mass production. If you need to modify your design or try different materials, small run injection molding allows for quick adjustments. This flexibility is particularly useful for companies testing new products in the market or experimenting with new designs.

4. Low Risk for Market Testing

With low-volume plastic molding, businesses can test new product designs in the market without the high investment associated with mass production. Small batches allow you to gather feedback from customers, identify potential issues, and refine the product before scaling up production.

5. High-Precision Quality

Despite the smaller production runs, short run injection molding can produce high-precision parts. With advanced technology and high-quality molds, you can expect components that meet strict specifications with minimal defects.

Real-World Case: Successful Collaboration in Consumer Electronics

Country: United States

Company: XYZ Consumer Electronics

Procurement Need: XYZ Consumer Electronics needed a solution for producing small-batch, custom enclosures for a new smart home product line.

Challenge: XYZ required precise, high-quality plastic parts for their new product, but they only needed a small number for their initial release. Mass production was not a feasible option, and they needed a partner who could deliver both quality and speed at a reduced cost.

Solution: By choosing low-volume plastic molding with our services, XYZ was able to create precise, custom enclosures within their budget and timeline. Our team worked closely with XYZ to optimize the design and ensure that the molds were efficient for short run injection molding.

Outcome: The custom enclosures exceeded XYZ’s expectations in both quality and production speed. The products were delivered on time, at a lower cost, and with minimal design adjustments. XYZ was able to meet its product launch deadlines, and customer feedback has been overwhelmingly positive.

FAQ

Q1: What is the difference between low-volume and mass production injection molding?

Low-volume injection molding focuses on producing small quantities, typically from a few dozen to a few thousand units. This is ideal for prototypes or testing new products. Mass production involves large-scale runs where the process is optimized for cost savings at high volume, usually with higher upfront investments.

Q2: Can low-volume plastic molding be used for functional prototypes?

Yes, small run injection molding is perfect for producing functional prototypes. This allows businesses to test product designs with high-quality, production-grade components before committing to mass manufacturing.

Q3: Is short run injection molding suitable for medical device manufacturing?

Yes, low-volume plastic molding is widely used in the medical device industry, where high precision and quality are required. It is ideal for creating custom medical components that need to meet stringent regulatory requirements.

Q4: How do you ensure the quality of parts produced in small run injection molding?

We ensure high-quality standards through precise mold designs, selecting appropriate materials, and conducting rigorous quality control processes. The low-volume nature of the production ensures that defects are minimized, and adjustments can be made quickly.

Conclusion: Maximize Efficiency with Low-Volume Plastic Molding

Whether you’re working on short run injection molding for prototypes or producing small run injection molding for custom products, this method offers significant advantages. It’s cost-effective, fast, flexible, and capable of producing high-quality parts that meet precise specifications.

If you’re looking for a reliable and efficient solution for your small-batch production needs, DTG is here to help. Contact us today to discuss how low-volume plastic molding can streamline your product development process and help you bring your products to market faster and more affordably.