Custom Plastic Mold Manufacturing — Precision, Innovation, and Reliability

At DTG Plastic Mold Manufacturing, we specialize in ultra-precision custom mold making with a proven reputation for excellence across multiple industries. As a trusted injection molding company based in China, we deliver high-quality, multi-cavity, and complex molds designed to meet the most demanding standards.

Certified under ISO 9001:2015, AS9100D, and ITAR, DTG combines advanced technology, state-of-the-art machinery, and cutting-edge design software to ensure the highest level of precision and consistency. Our expert engineering team and systematic production processes guarantee reliable performance and cost efficiency in every project.

We proudly serve industries such as pharmaceuticals, medical devices, healthcare, nutrition and food packaging, information technology, office automation, automotive, and consumer electronics. Whether you need precision molds for medical applications or intricate tooling for automotive components, DTG delivers innovative, durable, and cost-effective manufacturing solutions to help your business grow.

👉 Trusted Custom Mold Making Service — Get a Quote in Just One Days!

DTG Mold Manufacturing Process

01

Mold 2D/3D Design

Mold 2D/3D Design involves creating, simulating, and testing a mold design using CAD software for efficient and accurate manufacturing.

02

Mould Production

Mould Production involves mould design, material selection, machining, assembly, and testing for mass production.

03

Mould Trial

The Mould Trial tests injection molds, producing and inspecting parts to ensure design specifications and quality before full-scale production.

04

Mould Delivery

Sample Inspection involves examining prototypes and initial production samples for design accuracy, quality control, and continuous improvement.

Equipments & Process

In the world of mold manufacturing, equipment and processes are critical, and DTG understands this, which is why we continually invest in advanced manufacturing equipment and process technology, and ensure that our team is always up-to-date on the latest manufacturing methods and skills.

CNC

Milling Center

AQ360-550

Wire Cutting Equipment

1370CNC

EDM(Electrical Discharge Machining)

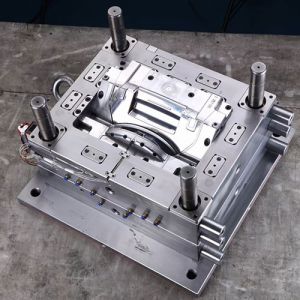

Case Studies

Manufactured through DTG

Why Choose DTG Injection Molding Services ?

ISO Certified

ISO Certified

Expertise

Advanced Equipment

Fast delivery

Customer Focus

Our Mold Design Process

For simple parts, product lead times can be reduced to as little as 3 days.Upload your part to see if it qualifies.

01

Requirement Analysis

We start by thoroughly understanding the project requirements, including the part geometry, material properties, production volume, and budget constraints. This initial phase involves close collaboration with the client to gather all necessary information and establish clear design objectives.

02

Conceptual Design

Our team of skilled designers and engineers utilizes advanced CAD software to create conceptual designs based on the project requirements. This phase involves brainstorming innovative solutions and exploring various design options to achieve the desired functionality and manufacturability.

03

Detailed Design

Once the conceptual design is approved, we proceed to the detailed design phase. This stage involves refining the 3D model to incorporate all essential features, such as parting lines, gating systems, cooling channels, and ejection mechanisms. Our designers pay meticulous attention to detail to optimize the mold design for efficiency and performance.04

Simulation & Analysis

Once the conceptual design is approved, we proceed to the detailed design phase. This stage involves refining the 3D model to incorporate all essential features, such as parting lines, gating systems, cooling channels, and ejection mechanisms. Our designers pay meticulous attention to detail to optimize the mold design for efficiency and performance.

05

Design Review & Optimization

The design undergoes thorough review by our team of experts, where potential issues or areas for improvement are identified and addressed. We collaborate closely with the client to incorporate feedback and make any necessary adjustments to optimize the mold design for manufacturability and functionality.

06

Prototype Development

Upon finalizing the design, we proceed to prototype development to validate the mold’s functionality and performance. This stage involves manufacturing prototype molds and conducting rigorous testing to ensure they meet the client’s requirements and quality standards.

07

Finalization & Production Release

Once the prototypes are successfully tested and approved by the client, we finalize the mold design and release it for full-scale production. Our team closely monitors the manufacturing process to ensure the molds are fabricated to the highest standards and deliver consistent, high-quality parts.

08

Continuous Improvement

At Omni, we are committed to continuous improvement and innovation. We regularly evaluate our mold design process to incorporate the latest technologies, best practices, and customer feedback, ensuring we deliver exceptional results with every project.