Injection Molding: Providing Efficient and Custom Solutions for Your Products

In modern manufacturing, injection molding is widely used across industries, from electronics and automotive components to medical devices. As a precise and efficient manufacturing process, injection molding can meet the demands of large-scale production while ensuring the accuracy and consistency of each part. As an injection molding manufacturer, we have deep expertise in this field and are committed to providing top-notch injection molding services to customers around the world. This article will introduce the advantages of our custom injection molding company and how we help you bring your products to market faster and more efficiently through innovative manufacturing processes.

What is Injection Molding?

Injection molding is a manufacturing process where melted materials, such as plastics, metals, or rubber, are injected into molds and then cooled and solidified to form the final part. Due to its high efficiency and precision, injection molding is widely used for mass production. Whether making small electronic parts or large automotive components, injection molding offers high production efficiency and exceptional precision.

Why Choose Our Injection Molding Manufacturing Company?

As an ISO 9001:2015 certified and ITAR-registered injection molding company, our production processes strictly follow international standards to ensure the quality and compliance of every product. From the design of the first mold to mass production, we pay attention to every detail and strive for perfection. We not only focus on production efficiency but also prioritize the flawless presentation of each part. Below are several core advantages of our injection molding services:

- Precise Injection Molding Process

We employ advanced injection molding techniques to ensure every part maintains consistency and flawless quality. Through strict tolerance control, we ensure all products precisely match the client’s needs and design vision. Whether it’s complex geometries or minute size tolerances, we can provide perfect solutions. - Fast Prototyping and Flexible Production Capabilities

As a custom injection molding company, we offer flexible production models to support varying needs, from rapid prototyping to large-scale production. With our high-output systems, you can enter the market faster and shorten the product development cycle. Whether you need short-term production or millions of units, we can offer scalable production capabilities to grow with your business. - Cost Reduction and Increased Efficiency

Our injection molding manufacturing process focuses not only on quality but also on optimizing material usage, reducing waste, and lowering the cost per part. With innovative manufacturing processes and advanced equipment, we can accelerate cycle times while maintaining part quality, providing cost-effective solutions. This makes us a reliable injection molding company partner, helping you stand out in a competitive market. - Wide Material Selection

At our injection molding company, we offer a wide range of thermoplastics, including common materials like ABS and polypropylene, as well as high-performance polymers to ensure your product achieves the perfect balance of durability, flexibility, and aesthetics. Whether your product requires high strength, heat resistance, or chemical corrosion resistance, we can provide tailored material solutions.

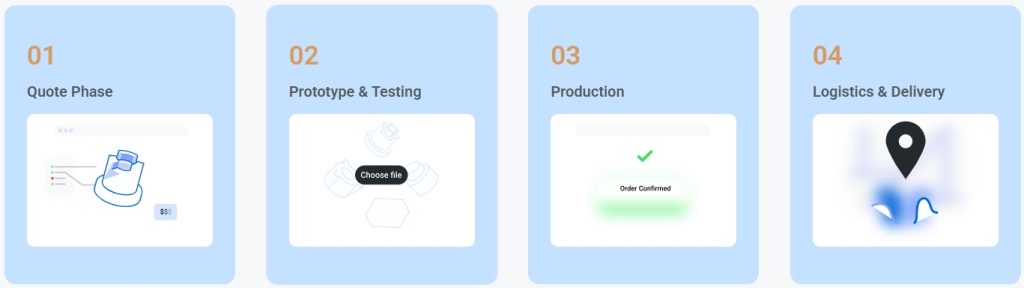

Injection Molding Production Process

To ensure each product meets the highest standards, our injection molding production process is divided into several key stages, each of which is strictly controlled and optimized:

- Quotation Phase

During this stage, we evaluate the design and requirements provided by the client, ensuring the quotation accurately reflects the project’s complexity and scale. Our team will provide a clear and transparent quotation, ensuring no hidden costs, allowing you to make a confident decision. - Prototyping and Testing

Before formal production begins, we create prototypes based on design requirements and conduct a series of rigorous tests. This step is designed to verify that the design meets expectations, ensuring potential issues are identified and resolved before large-scale production. - Production

Once the prototype passes testing, we proceed to formal production. Using advanced injection molding technology, we achieve mass production while ensuring precision. We promise timely delivery to ensure your product is smoothly brought to market. - Logistics and Delivery

After production is completed, we partner with reliable logistics providers to deliver the finished products to your designated location. Whether you require domestic delivery or international shipping, we offer efficient and economical logistics solutions.

Why Choose Us?

- Professional Experience and Expertise

With over 15 years of industry experience, we have accumulated extensive knowledge and practical experience in injection molding. We are committed to technological innovation, using the latest equipment and software to ensure each step of the production process is in optimal condition. - Sustainability and Environmental Practices

We focus not only on production efficiency but also on environmental responsibility. By optimizing the production process, we significantly reduce material waste and lower carbon emissions, offering sustainable manufacturing solutions to clients. - End-to-End Services

From design to delivery, we provide comprehensive injection molding services. Our team offers professional support throughout every stage of production to ensure your needs are fully met. - Customized Solutions

Every client’s needs are unique, and we provide customized solutions to help clients create tailor-made injection molding products. Whether you require mass production or small-batch custom work, we offer the most suitable services for your needs.

What Factors Should Be Considered When Choosing a Supplier?

Question: What factors should I consider when selecting a supplier?

Answer: When choosing a supplier, it’s essential to evaluate their qualifications, experience, and production capabilities. Ensure the supplier has relevant certifications (e.g., ISO 9001) and extensive injection molding experience. Additionally, check if their production equipment is advanced enough to meet your requirements. Past collaboration cases are also valuable in assessing the supplier’s capabilities.

How to Ensure the Quality of Raw Materials?

Question: How do I ensure the raw materials used in injection molding meet quality standards?

Answer: To ensure raw material quality, select reliable suppliers who provide materials that meet industry standards and quality requirements. You can request certifications and inspection reports from the supplier and perform sample testing. It’s also important to confirm the supplier’s material supply stability to avoid production delays due to shortages.

What is “Design for Manufacturability” (DFM) and Why Is It Important?

Question: What is “Design for Manufacturability” and why is it important in injection molding procurement?

Answer: Design for Manufacturability (DFM) refers to designing products in a way that aligns with injection molding processes to enable efficient production. This concept is crucial because designs that do not meet injection molding requirements can lead to production difficulties, increased costs, or product defects. Therefore, before procurement, product designs must undergo engineer review to ensure they are suitable for injection molding.

How to Ensure Timely Delivery?

Question: How can I ensure that the supplier delivers on time?

Answer: First, clearly define the delivery timeline with the supplier and include penalties for delays in the contract. Then, maintain regular communication with the supplier to track production progress and address potential issues. Additionally, consider setting up inventory alerts to handle unexpected order demands and production delays.

Conclusion

Choosing a reliable injection molding manufacturer is critical for any manufacturing business. We provide everything custom injection molding companies need, from precise manufacturing techniques to efficient production capabilities, helping you reduce costs and increase market competitiveness. If you are looking for a company to meet your injection molding needs, we are undoubtedly your best partner. Whether your needs involve rapid prototyping or mass production, we can offer the ideal solution.

Contact us to learn more about our injection molding manufacturing company and let us lay the foundation for the success of your product!

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|