Aluminum itself cannot be injection molded in the traditional sense used for thermoplastics. Injection molding typically involves melting a material and injecting it into a mold where it cools and solidifies. Aluminum, being a metal with a much higher melting point and different flow characteristics compared to plastics, does not lend itself to this process. However, there are alternative methods for molding aluminum that achieve similar results for creating complex shapes and high-precision parts. These methods include:

1. Die Casting

Overview: Die casting is the most common method used to mold aluminum into specific shapes. In this process, molten aluminum is injected into a steel mold (die) under high pressure.

Process:

- Melting: Aluminum ingots are melted in a furnace.

- Injection: The molten aluminum is injected into a steel die under high pressure.

- Cooling: The aluminum solidifies quickly within the die.

- Ejection: The die opens, and the solid aluminum part is ejected.

Applications: Automotive parts, housings, engine components, and other complex metal parts.

[elementor-template id=”4330″]

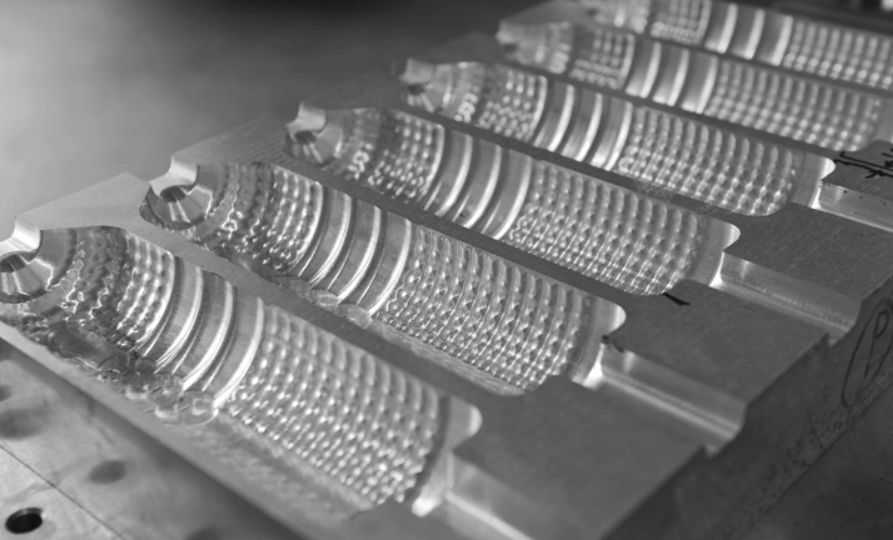

2. Aluminum Injection Molding for Tooling (Aluminum Molds for Plastic Injection)

Overview: Aluminum can be used to make molds for plastic injection molding. These molds are preferred for prototyping and low to medium volume production due to their lower cost and ease of machining compared to steel molds.

Advantages:

- Cost-Effective: Lower cost and faster machining compared to steel molds.

- Thermal Conductivity: Excellent thermal conductivity, leading to faster cycle times.

- Lightweight: Easier to handle and change out in the injection molding machine.

3. Thixomolding (Semi-Solid Metal Injection Molding)

Overview: Thixomolding is a process similar to injection molding but is used for metals, including aluminum and magnesium alloys. It involves injecting semi-solid metal into a mold.

Process:

- Material Preparation: Aluminum alloy is heated to a semi-solid state.

- Injection: The semi-solid metal is injected into a mold under high pressure.

- Cooling and Solidification: The metal cools and solidifies in the mold.

- Ejection: The part is ejected from the mold.

Applications: Lightweight structural components, electronic housings, and other precision parts.

Comparison of Methods

| Method | Material State | Temperature | Pressure | Applications |

|---|---|---|---|---|

| Die Casting | Molten | High | High | Automotive parts, housings, engine components |

| Aluminum Molds | Solid (for plastics) | Room temperature | Low to medium | Prototyping, low to medium volume plastic parts |

| Thixomolding | Semi-solid | Moderate | High | Lightweight structural components, electronic housings |

[elementor-template id=”4331″]

Conclusion

While aluminum cannot be injection molded in the same manner as plastics, alternative processes such as die casting, using aluminum for plastic injection molds, and thixomolding enable the production of complex and high-precision aluminum parts. Each method has its specific advantages and applications, making it essential to choose the right process based on the requirements of the part being produced.

Related Conten: https://www.m-dtg.com/landing-page/injection-molding-factory/

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|