In injection molding, a cam is a mechanical component used to create complex part geometries that include undercuts or side actions which are not aligned with the main opening and closing direction of the mold. Cams are an essential part of the mold design when standard two-part molds are insufficient to form the desired part features.

Functions and Importance of Cams in Injection Molding:

- Creating Undercuts:

- Undercuts are features that are recessed or protrude in such a way that they prevent the molded part from being ejected from the mold in a straight line. Cams allow for the creation and removal of these features by moving side actions or lifters that form the undercuts.

- Facilitating Side Actions:

- Side Actions are moving sections of the mold that create features on the side of the part. Cams control the movement of these side actions, which typically slide in and out perpendicular to the main mold opening direction.

- Enhancing Part Design Flexibility:

- Cams enable more complex and detailed part designs, including intricate shapes and internal features that would otherwise be impossible to mold with a standard two-part mold.

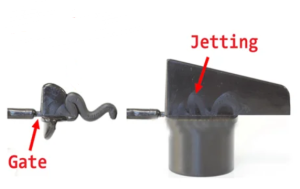

- Improving Part Quality:

- By allowing for proper formation and ejection of parts with complex geometries, cams help in maintaining high-quality standards and reducing defects such as drag marks, deformation, or incomplete part formation.

How Cams Work in Injection Molding:

- Cam Mechanism:

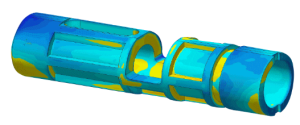

- A cam mechanism involves a cam pin or cam slide that moves laterally (sideways) relative to the mold’s primary opening and closing action. This movement is typically synchronized with the mold’s opening and closing cycle.

- Operation Sequence:

- Mold Closing: When the mold closes, the cam pin engages and moves the cam slide into position, forming the undercut or side feature on the part.

- Injection: Plastic is injected into the mold cavity, filling the space around the cam slide and creating the desired part features.

- Cooling: The part is allowed to cool and solidify in the mold.

- Mold Opening: As the mold begins to open, the cam pin disengages, causing the cam slide to retract and clear the undercut or side feature.

- Ejection: The part is then ejected from the mold without interference from the previously formed undercuts or side features.

Choose us for your custom injection molding needs and experience excellence in every detail. Our China-based factory provides innovative solutions, competitive pricing, and fast turnaround times. Get your custom quote now!

Example:

Consider a plastic part with a hook feature that protrudes sideways from the main body. Using a cam mechanism, the mold can include a cam slide that forms the hook. As the mold opens, the cam slide retracts, allowing the hook to be released from the mold without damage.

Conclusion:

Cams in injection molding are critical for enabling the production of parts with complex geometries that include undercuts or side actions. They provide the necessary movement to form and release these features, thereby enhancing the design flexibility, functionality, and quality of molded parts.

Related Conten: Prototype Injection Molding