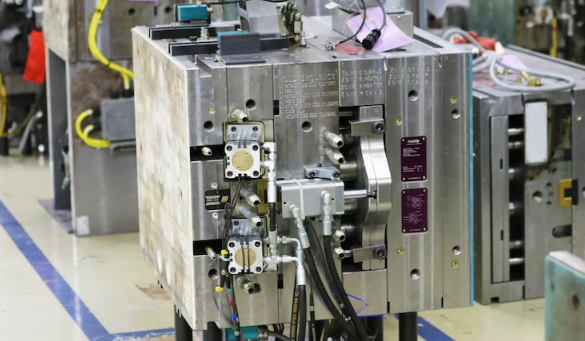

Changing an injection mold involves several steps to ensure a smooth transition from one mold to another while maintaining production…

Blogs

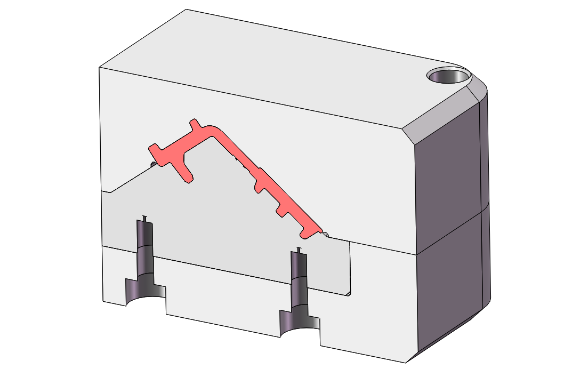

Avoiding undercuts in injection molding is crucial to ensure that parts can be ejected from the mold without damaging either…

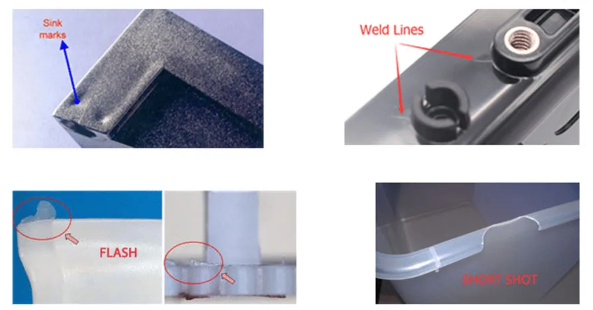

Avoiding sink marks in injection molding is crucial for achieving high-quality plastic parts with uniform surface appearance and dimensional accuracy….

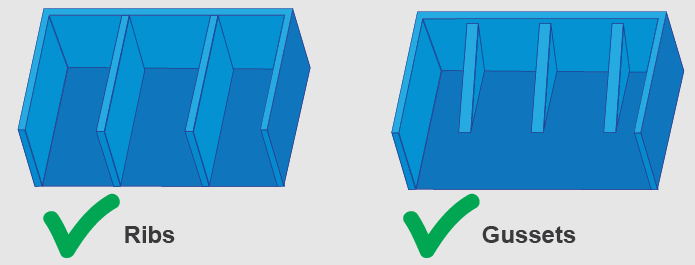

Overview Ribs in injection molding are thin, vertical structures added to the design of plastic parts to provide additional support…

Injection molding is a highly efficient manufacturing process, but it can be prone to various defects that affect the quality…

Plastic injection molds are made from a variety of materials, each chosen for its specific properties to ensure the mold’s…

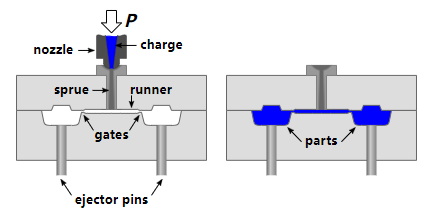

Understanding Injection Points In injection molding, the point where molten plastic enters the mold cavity is crucial for ensuring the…

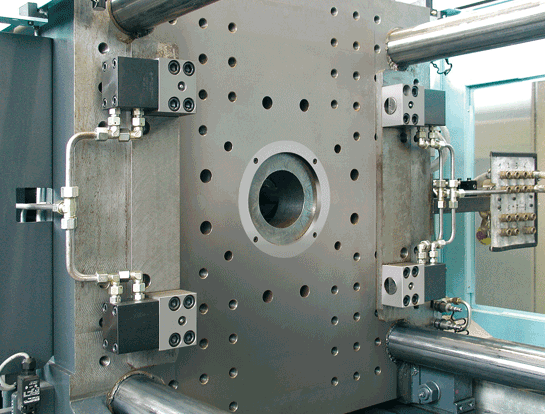

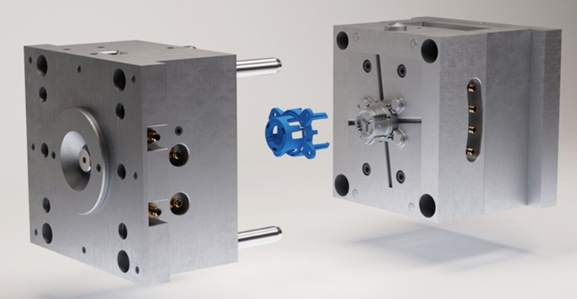

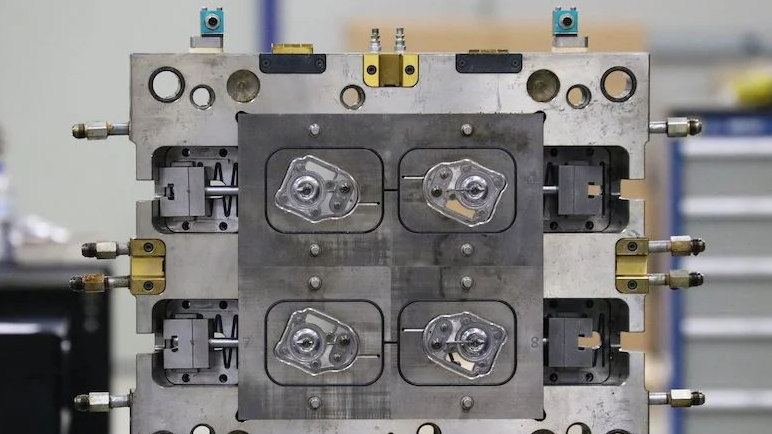

Injection molds are precision tools used in the injection molding process to shape molten plastic into desired forms. These molds…

Injection molding molds, also known as dies or tooling, are crucial components in the injection molding process. The choice of…

What are Injection Molding Machines? Injection molding machines are industrial devices used to manufacture plastic products by injecting molten plastic…